FOULING-IMMUNE MEMBRANE TECHNOLOGY FOR

Meat & Poultry

Forget everything you know about membranes in the meat and poultry industry. With ZwitterCo, plants can eliminate or reduce inline DAF chemical dosing while meeting discharge limits, reuse up to 95% of their water, reduce costs for functional protein concentration, and improve RO polishing.

ZwitterCo Membrane Filtration Results:

Left: Raw Wastewater

Middle: Permeate

Right: Reject/Concentrate

Edison Award

ZwitterCo superfiltration membranes received a Bronze award for innovation in the Water Treatment & Testing category at the 2024 Edison Awards.

This award highlights their impact on the meat and poultry industry, enabling > 99% removal of FOG and TSS.

Featured in US Poultry

Little Blurb about US Poultry Feature and a link to it.

Read More

Fouling-Immune Membrane Technology is Finally Ready for Meat & Poultry.

ZwitterCo developed an award-winning, entirely new class of membrane technologies that solve the number one problem with membranes: fouling. Our zwitterionic technology is the foundation for fouling-resistant membranes that clean the most challenging wastewaters and surface waters – faster and easier than any membrane in history. ZwitterCo membranes can operate for years in environments that would ruin traditional membranes in days or weeks.

Meat & Poultry Solutions

What Challenges Can ZwitterCo Technology Solve For You?

Meet Discharge Limits

Achieve over 99% FOG and TSS removal from wastewater, eliminate or reduce inline DAF chemical dosing, and ensure discharge compliance.

Reuse Water & Intervention Chemicals

ZwitterCo pretreatment can offset the rising cost of water and chemicals. This helps to achieve over 95% water reuse and recover over 90% of intervention chemistries in protein process applications.

Functional Protein Concentration

ZwitterCo membranes provide easier, shorter cleanings that require less chemicals which allows for safe land application and valorization opportunities.

ROWaterPurification

ZwitterCo RO membranes are perfect for existing reverse osmosis systems treating MBR effluent that are struggling with frequent high pH cleaning.

SOLUTION #1

Meet Your Wastewater Discharge Limits

Replace or Augment Infrastructure for Wastewater Treatment & Reduce OPEX

ZwitterCo superfiltration (SF) membranes can replace DAF entirely or improve operations by converting your DAF to air only, which would lower overall costs of ownership by eliminating the need for DAF polymer and coagulants and reducing cleaning frequency.

- Greenfield expansion capacity with compact footprint

- Eliminate DAF polymer and coagulants

- Reduce cleaning frequency

- Valorize concentrate for pet food, fertilizers, etc.

Reduce Maintenance Downtime & Plant Upsets

ZwitterCo membranes support automated operations, reducing the need for human intervention and minimizing frustrations that come with other wastewater systems such as air flotation, lagoons, etc.

ZwitterCo SF membranes are immune to irreversible fouling, reducing the frequency and duration of downtime associated with traditional system maintenance and plant upsets.

- Immune to irreversible fouling

- Reduce downtime

- Increased automated operations

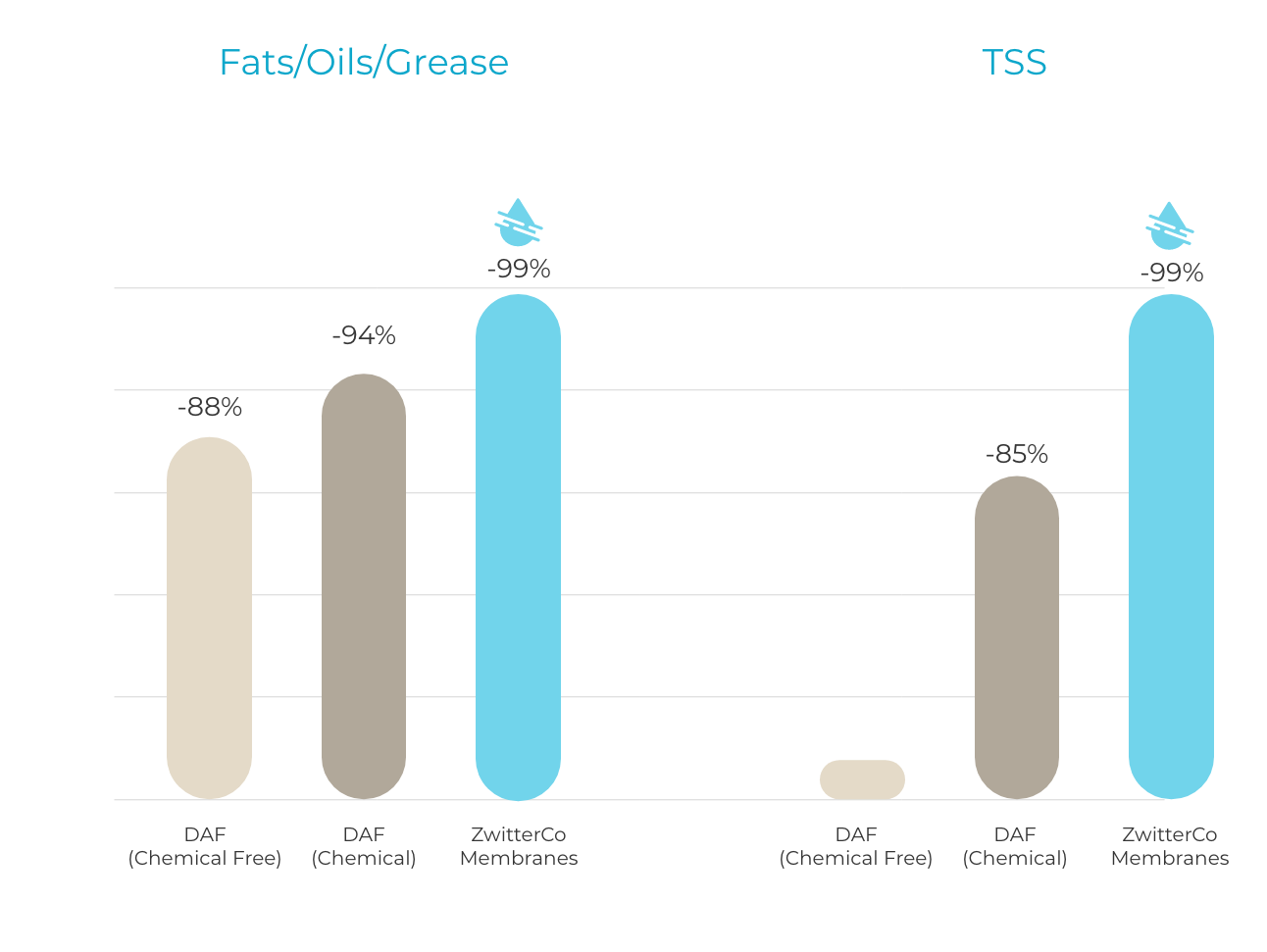

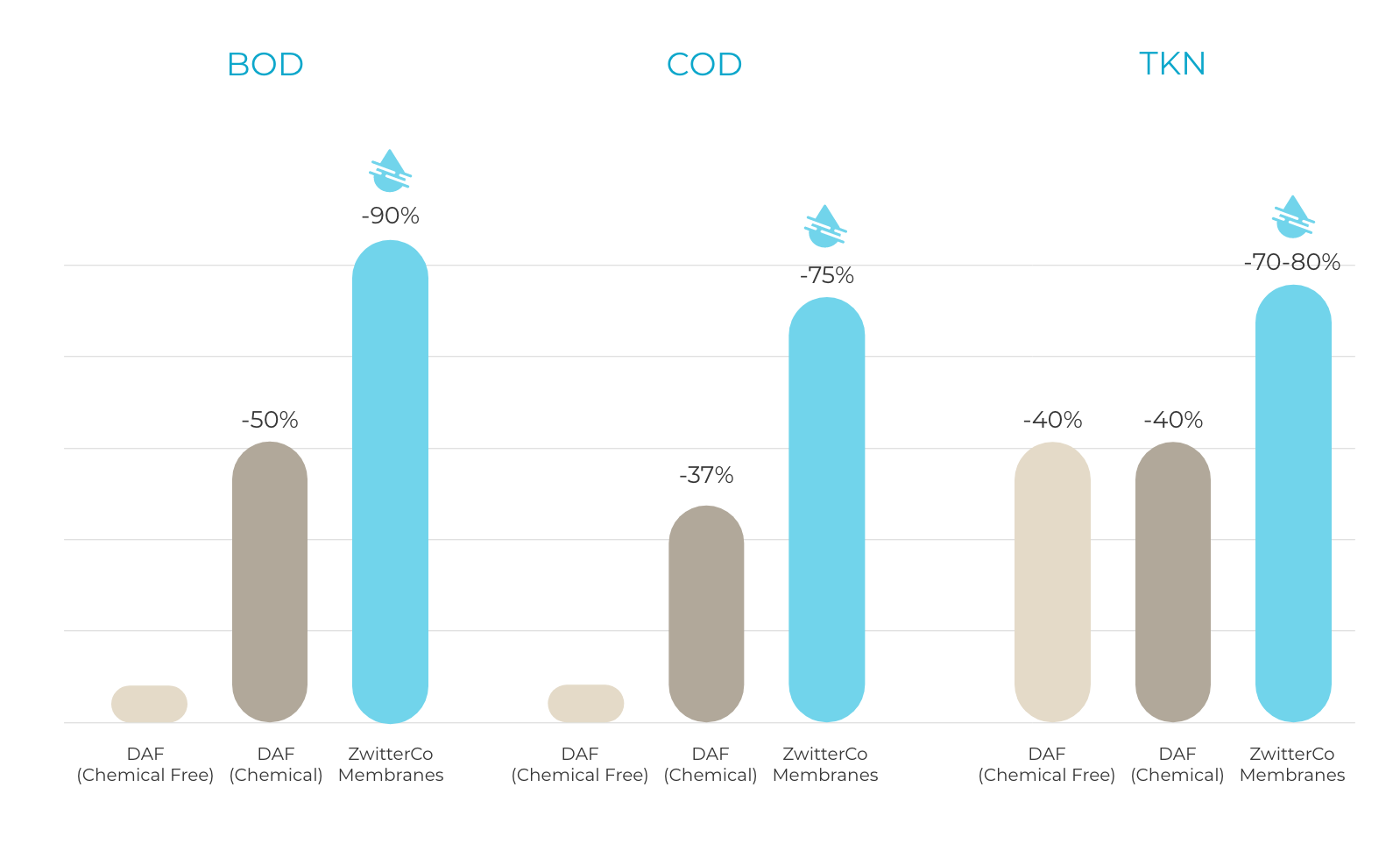

ZwitterCo membranes versus DAF

Improve Wastewater Quality & Meet Discharge Limits

Achieve > 99% removal of fats, oils, and grease (FOG) and TSS with ZwitterCo SF, resulting in cleaner effluent and higher quality reclaimed water, surpassing the inconsistent performance of DAFs. This also allows for consistent compliance with discharge limits.

Increase Operational Reliability

By decreasing the dependency on manual in-line chemical dosing processes, ZwitterCo membranes lead to fewer operational disruptions, resulting in smoother and more efficient plant operations.

ZwitterCo membranes are extremely resilient to sudden changes in feed quality, ensuring stable performance and fewer plant upsets. They also do not require any operator involvement in making the necessary changes.

APPLICATION BRIEF

Ditch the DAF: Next-Gen Wastewater Treatment with ZwitterCo Membranes

Coming soon.

SOLUTION #2

Reuse Water & Intervention Chemicals

From left to right: Raw feed water from poultry processing plant, ZwitterCo superfiltration permeate (97%), concentrate (3%), and RO polish water.

Enable Water Reuse in Upstream Processes

ZwitterCo SF membranes can remove greater than 99% of the oil, grease, and TSS within that water stream, which minimizes nozzle clogging and decreases TOC and BOD up to 90%.

Ideal Pretreatment for RO

ZwitterCo SF membranes provide the best pretreatment for further refining to RO quality by reducing constituents that cause poor membrane performance.

Lower the Cost of Intervention Chemistries

ZwitterCo’s fouling-immune SF membrane technology enables over 95% recovery of process water streams such as screen wash water and other washdown areas for reuse. You can achieve all this while removing color, FOG, TSS, BOD, TOC, and TKN.

SF also allows chemicals such as PAA to pass while capturing FOG. This allows over 90% of intervention chemistries, such as PAA, to be reused.

Recent third-party lab testing of ZwitterCo membranes versus DAF.

ZwitterCo Reuse Water Applications

- Screen Wash Water

- IOBW

- Carcass Washes

- Vacuum Pumps

- Irrigation

- Dip Tanks

ZwitterCo provides a significant reduction in the amount of wastewater produced by your facility.

Reduce Volume of Wastewater Treated

Wastewater from process streams contributes to the load on total plant wastewater. With ZwitterCo membranes, you’re able to reduce the volume of wastewater that needs to be treated.

ZwitterCo membranes allow for water reuse and recycling in places that may not have been able to be reused before, which leads to less wastewater going to total plant WW treatment.

SOLUTION #3

Functional Protein Concentration

Concentrate after ZwitterCo membrane filtration.

Eliminate The Need for Chemicals

Many plants use polyacrylamides, aluminum and iron-based chemicals in their DAFs, which can poison aquafers. Our filtration provides concentrate similar to DAF skimmings but without the chemicals.

With ZwitterCo, No Need For:

- Polyacrylamides

- Aluminum

- Iron-Based Chemicals

Land Application & Composting Without DAF Chemistries

The reduction in chemicals using ZwitterCo membranes means that plants can use treated water without worrying about increasingly strict regulations.

In many places around the United States, new strict rules have made land application difficult or impossible. With ZwitterCo, land application and composting are possible – even as regulations change. This opens the door to valorization opportunities as well.

Safe Rendering Material

With ZwitterCo membranes, plants can capture all the oils, grease, and proteins, boosting yields and production at the rendering plant. ZwitterCo membranes also provide safer byproducts for animal food, without polyacrylamide – a chemical harmful to humans and animals.

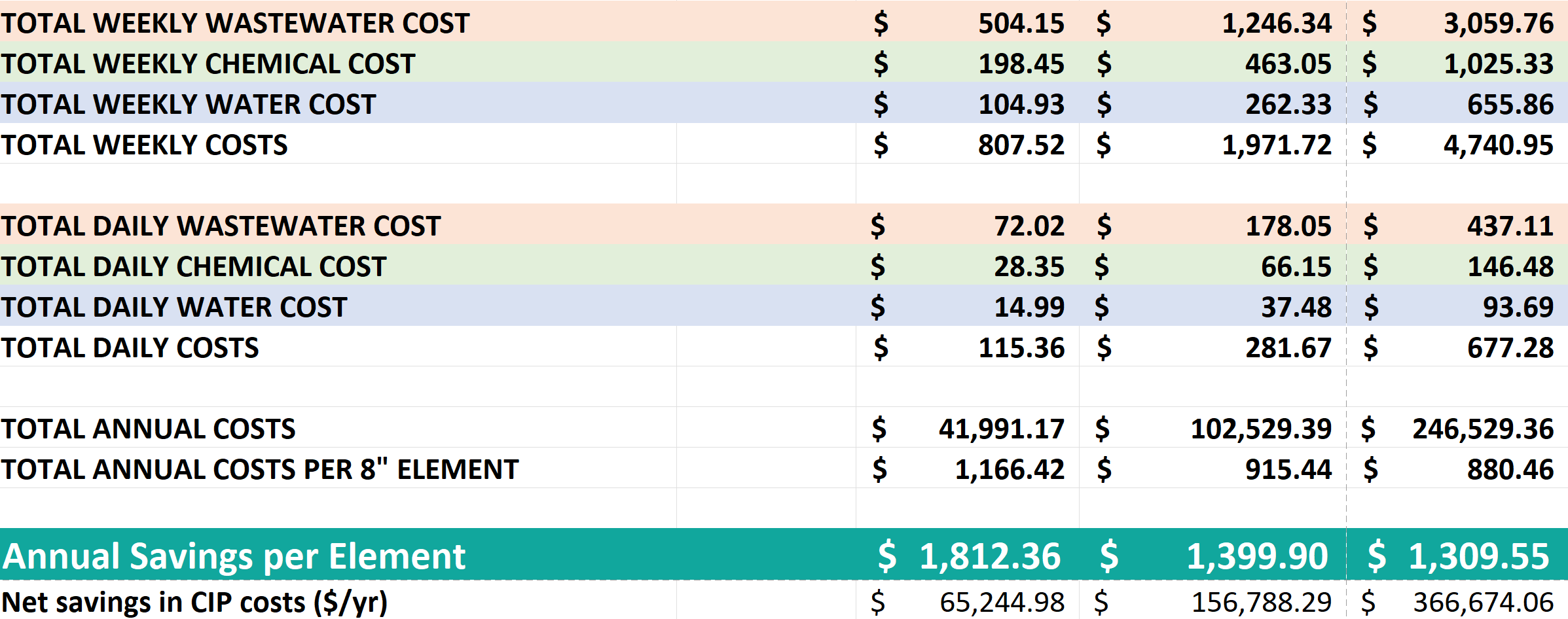

FREE DOWNLOAD: ECONOMIC MODEL

Concentrating Protein?Cut CIP Costs in Half.

ZwitterCo is now implementing our fouling-immune technology and designing sanitary products specific for food, dairy, and beverage processes that enable a daily 1-step clean plus sanitization.

A simple drop-in replacement will cut cleaning costs by >50% by reducing chemicals, make-up water, wastewater, and energy. Additionally, chlorine is not required to restore membrane performance.

Use ZwitterCo’s economic savings tools to model the potential savings in your systems. Download today!

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

SOLUTION #4

Reverse Osmosis (RO) for Water Purification

Reduce Frequent Cleaning & Lower OPEX

ZwitterCo RO is perfect for existing RO systems treating MBR effluent that are struggling with frequent high pH cleaning. Built using fouling-immune technology, ZwitterCo RO reduces cleaning frequency by up to 90%, offering 2x membrane lifespan, and lowering overall costs.

- Enhanced with fouling-immune technology

- Up to 90% less cleaning

- Significantly reduced chemicals

- 2x membrane life

Free eBook: The Future of RO

Increase Production & Uptime with Fouling-Immune Technology

RO technology that offers the ultimate time and money-saving solution.

Discover your potential savings with our free eBook, available for download here.

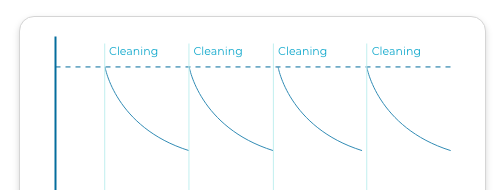

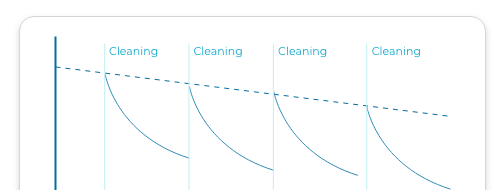

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

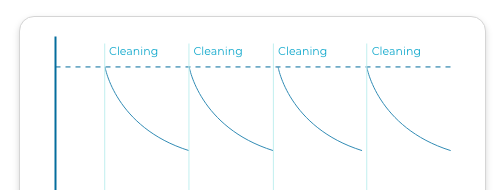

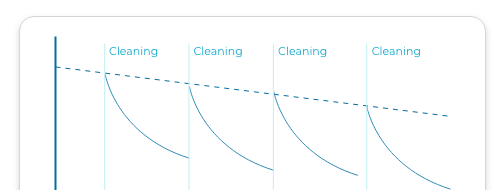

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

No wear and tear

Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

Short lifespans from degradation

Compromised performance