SignificantCost Savings

Pre-concentrating liquid organic waste streams directly reduces the volume and cost of offsite hauling.

ImprovedSustainability

Onsite water reuse helps reduce trucks on the road and lowers a facility’s freshwater footprint.

Community Relations

Avoid wastewater hauling, tanker spills, and nuisance violations from passing through urban centers.

Water as a Service

With our partners, ZwitterCo can offer clean water-as-a-service – minimal upfront capital required.

Clean water and ZwitterCo superfiltration concentrate from manure digestate.

A Total Re-Haul of

Wastewater Treatment

Offsite wastewater hauling is a simple way to get rid of your waste, especially when there isn’t easy access to municipal or environmental discharge. However, moving water by truck is an expensive and unsustainable disposal method.

Depending on the composition of your wastewater, extracting as much water as possible ahead of hauling can yield significant operational and community benefits. Additionally, advanced treatment opens the door to water reuse and creating new co-products and revenue streams from waste.

ZwitterCo’s superfiltration technology drastically reduces hauling volumes by helping recover water you can use.

Filter out fat

to make clean water

from every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

Reimagine your Wastewater

Using ZwitterCo technology to remove as much water as possible from your fluid prior to disposal is an immediate step you can take to yield significant operating savings.

Reduce Offsite Hauling

ZwitterCo Membranes offer significant benefits by reducing digestate volume by up to 50%, concentrating NPK for organic fertilizer production, and lowering the carbon intensity score.

Concentrated Nutrients

ZwitterCo membranes efficiently concentrate nutrients, resulting in a smaller volume of concentrate for easy storage and the ability to create a saleable product from excess nutrients.

Easy Land Application

ZwitterCo membranes facilitate easy land application by producing concentrated fertilizer that requires less volume to spread, does not clog pivots, and results in reduced odor on the land.

Reducing Treatment Costs by $1.5M/Year

ZwitterCo’s breakthrough membrane technology enables filtration for the most challenging separations. The membrane can handle streams with over 25,000 ppm chemical oxygen demand (COD) and total solids (TS). It offers full performance recovery after a mild maintenance wash, and lasts for years in streams that would ruin standard membranes in days. See the difference in this manure digestate example:

Original Process (Before ZwitterCo)

- $3M/year hauling manure digestate

- Soil and groundwater contaminant regulations

New Process With ZwitterCo

- RO concentrate captures ammonia-based nitrogen as a saleable organic fertilizer

- ZwitterCo superfiltration rejects all dissolved foulants, protecting the downstream RO process

- Enabled consistent, sustainable generation of a reusable or dischargeable clean water stream

- Treatment costs reduced by $1.5M/year

- Commercial installation based on pilot results

ZwitterCo superfiltration (permeate in the center) enables this treatment process by protecting the RO from small molecule, heavy foulants. The result is the consistent generation of a highly concentrated nutrient stream (second from the right) and a reusable or dischargeable clean water stream (far right).

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

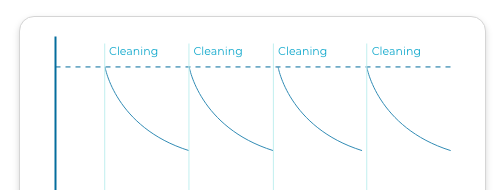

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

No wear and tear

Reliable treatment quality

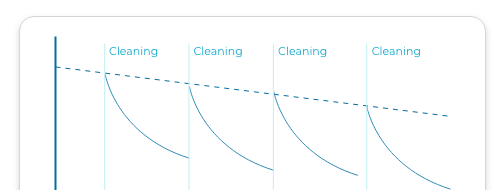

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

Short lifespans from degradation

Compromised performance