Fats, Oils, and Grease (FOG) up to 5%

Handle unprecedented levels of FOG and other hard-to-treat organics with membranes that will fully recover with a simple maintenance wash

CleanwithChlorine

Superfiltration membranes can handle >1MM ppm-hours of chlorine, peracetic acid, and other cleaning agents, showing unmatched chemical resilience

Ultra-HighWaterRecovery

Maximize the clean water you generate with clean-water-recovery ratios that regularly exceed 90%.

Highly Compact Footprint

Compact modular filtration systems can be engineered for space-constrained environments, saving your footprint for future expansions.

Filter out fat

to make clean water

from every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

ZwitterCo Superfiltration Membrane Spec Sheets

ZwitterCo Superfiltration

A Paradigm Shift in Membranes

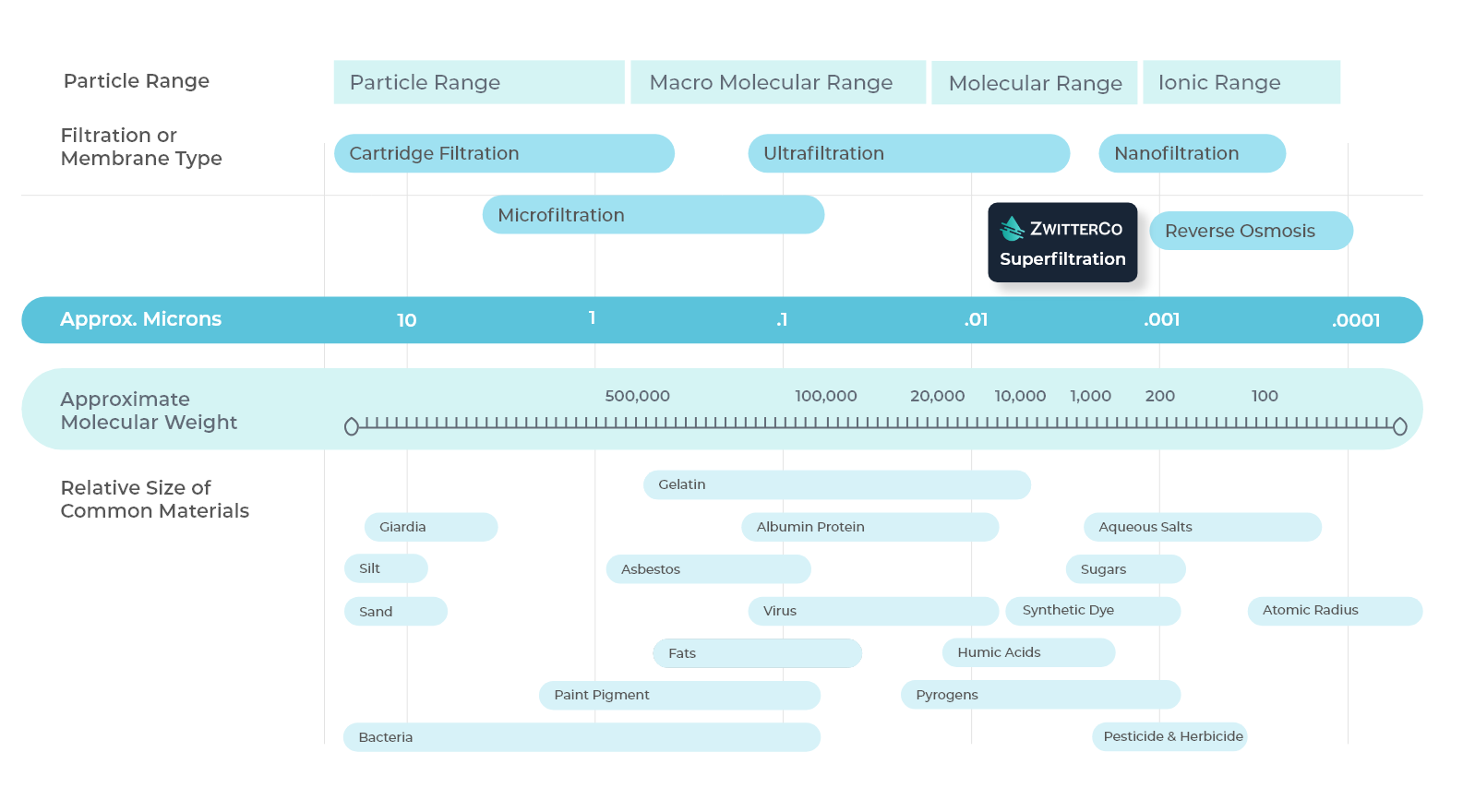

Superfiltration membranes are a new separation class between ultrafiltration and nanofiltration. ZwitterCo membranes deliver unprecedented fouling resistance, low energy requirements, wide pH tolerance, and the ability to be cleaned with chlorine.

Superfiltration membranes are designed for fractionating dissolved components, like capturing protein while passing inorganic molecules. Our SF membranes are engineered tightly enough to remove fats, oils, grease (FOG), and high-strength organics, providing ideal pre-treatment for reverse osmosis in wastewater.

Contact us today.

Learn about the technology.

What is Superfiltration?

Membranes in this class may be described as “tight UF”, “open NF”, and “thin-film UF”.

High Organic / Low Salt Rejection

Superfiltration membranes demonstrate high NF-like organic rejection and low UF-like salt rejection.

Molecular Weight Cut-Off

Commonly have a molecular weight cut-off (MWCO) between 500 – 3,500 Daltons and low monovalent ion rejection (< 15%).

Removal of FOG, TSS, and Turbidity

Complete removal of FOG, TSS, and turbidity from dairy wastewater or poultry wastewater. It will remove larger dissolved organic compounds like proteins, polysaccharides, and humic acids.

What Makes ZwitterCo Superfiltration Unique?

Organic Fouling Resistant

Unique organic fouling resistance with zwitterionic membrane technology.

Designed for Extremes

Designed for extreme concentrations (e.g. >500,000 ppm-hours) of chemicals like chlorine, peracetic acid, and aqueous ammonia, as well as a wide range of pH.

Suspended Solids Removal

Removes dissolved and suspended compounds larger than 1 nanometer/1 kDa molecular weight, providing ideal feedwater to reverse osmosis.

Reimagine your Wastewater

The status quo for high-strength wastewater treatment is expensive and unsustainable. Superfiltration brings the precision and reliability of SF membranes to historically unfilterable streams.

Superfiltration

Reduces or

Replaces

Hauling

Trucking is the most expensive and least sustainable means of managing wastewater. ZwitterCo’s superfiltration technology drastically reduces wastewater hauling volumes by helping recover water you can use.

Superfiltration

Replaces or Supplements

Biology

Biological processes take up a lot of land area and have frequent upsets, especially when treating hard-to-break-down waste compounds. Superfiltration systems need only a fraction of the floor space and will handle complex organic streams.

Superfiltration

Replaces or Supplements

DAF

On top of the daily in-line chemical dosing and expensive sludge hauling, DAF processes notoriously yield inconsistent or insufficient treatment results. Superfiltration can reduce or eliminate the use of DAF chemicals, opening the door to waste-to-revenue opportunities, and delivering precise, high-quality effluent.

Superfiltration

Replaces or Supplements

Tubular

Tubular and other open-channel membrane configurations require high recirculation energy and can still incur severe operating costs from fouling. Superfiltration membranes use 5-10x lower energy and have the fastest and least expensive cleaning methods in the industry.

Industries We Serve

Industrial

- Industrial Wastewater

- Landfill Leachate

- Steel Finishing

- Oil & Gas

- Chemical Plants

Digestate

- Food Waste

- Cow Manure

- Swine Manure

- Chicken Litter

Food & Beverage

- General Food & Beverage

- Dairy Wastewater

- Sweeteners

- Meat & Poultry

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

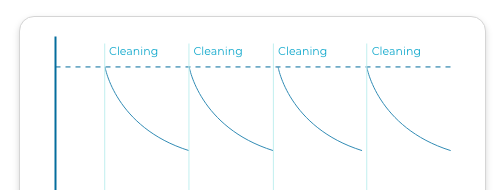

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

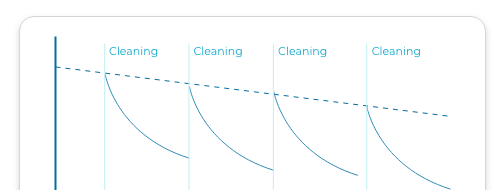

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance