Edison Award

ZwitterCo superfiltration membranes received a Bronze award for innovation in the Water Treatment & Testing category at the 2024 Edison Awards.

This award highlights their impact on the meat and poultry industry, enabling > 99% removal of FOG and TSS.

Featured in US Poultry

Little Blurb about US Poultry Feature and a link to it.

Read More

Fouling-Immune Membrane Technology that Maximizes Production and Reduces Cleaning.

ZwitterCo’s advanced membrane technology fully recovers with simpler and easier cleaning programs with fewer steps, allowing for reduced chemicals use, less freshwater demand, less energy, and minimized wastewater generation. This not only lowers operating costs but also aligns with sustainability goals.

Whether it’s improving your whey or milk protein operations, standardizing ingredients, or concentrating wastewater streams, ZwitterCo membranes provide unmatched performance and a lower cost of ownership.

Dairy Processing Applications

What Challenges Can ZwitterCo Technology Solve For You?

Whey & Milk Protein Concentration

ZwitterCo membranes cut CIP programs down by up to 6 steps, including flushes, helping processors reduce their cleaning costs by over 50%. Reduce chemical cleaners, freshwater demand, wastewater generated, and energy consumption to save time and money.

ProductConcentration

Concentrate whey and other products using ZwitterCo membranes to fully recover performance with a faster, lower cost cleaning program. Save about an hour for every cleaning step eliminated by simply replacing membranes with no capital investment required.

WastewaterConcentrators

With ZwitterCo RO, lower your hauling costs with more productive wastewater concentrators that enable lower cleaning costs by eliminating the daily enzyme step.

Whey & Milk Protein Concentration

Reduce Your Cleaning

Costs by 50%

With ZwitterCo membranes, your cleaning programs are easier and shorter, enabling more uptime and increased production.

With easier cleanings and less chemicals, plants enjoy significantly reduced time and labor required for maintenance.

Simplified

& Sustainable Operations

ZwitterCo membranes simplify cleaning processes and require fewer chemicals, while also reducing freshwater demand, energy consumption, and amount of WW generated.

Our membranes will help you meet your corporate sustainability targets, due to:

- Reduced pumping

- Less water

- Less heating of CIP solutions

- Decreased chemical usage

- Reduced energy requirements

Improve Your OPEX

Reduced Operating Costs

With lower cleaning costs, decreased water usage, less wastewater generated, and lower energy requirements, ZwitterCo membranes offer a significant decrease in OPEX.

Increase in Uptime

ZwitterCo membranes offer more up-time due to shorter cleaning programs which frees operators to work on other priorities.

Reduced Freshwater Demand

In whey protein concentration applications, ZwitterCo membranes significantly reduce freshwater demand through their simplified cleaning process.

Product Concentration

Simplify Cleanings / Reduce Chemical Usage

ZwitterCo advanced zwitterionic membranes offer easier, quicker cleaning that requires less chemicals, aligning with sustainability goals and cutting operational expenses for dairy processing companies.

Reduce OPEX

As a risk-free drop-in replacement, ZwitterCo membranes offer a decrease in OPEX and downtime without any additional CAPEX.

Overall costs are lowered due to the following:

- Less water usage

- Less wastewater generated

- Decreased energy requirements

- Lower cleaning/chemical costs

Meet Sustainability Goals & Reduce Freshwater Demand

Reduction in Freshwater Demand

Whether recovering water from wastewater or reducing water requirements through a simplified cleaning program, ZwitterCo membranes enable a reduction in freshwater demand.

Meet Sustainability Goals with No Additional CAPEX

By reducing chemical usage and decreasing freshwater demand, ZwitterCo membranes support more sustainable water treatment practices, helping dairy processors meet environmental regulations and sustainability goals.

Free eBook: The Future of RO

Increase Production & Uptime with Fouling-Immune Technology

RO technology that offers the ultimate time and money-saving solution.

Discover your potential savings with our free eBook, available for download here.

Wastewater Concentrators

Reduce Costly Wastewater Hauling

Integrating ZwitterCo RO membranes can reduce wastewater hauling volumes by 50% or more, lowering overall costs and increasing the sustainability of operations.

Reduce Operating Expenses

ZwitterCo RO membranes offer easy cleaning with full performance recovery after each wash, less chemical use, and less downtime, which all adds up to lower overall costs.

Removing the daily enzyme cleaning step cuts chemical costs by about 50% and saves about an hour of cleaning time, enabling more uptime or allowing operators to focus on other tasks.

Reduce

Footprint

Membrane processes are some of the most space-saving and footprint-flexible unit operations. ZwitterCo RO membranes offer wastewater concentration with a compact footprint.

BROCHURE

What Would You Do With More Time?

Think about it – every step of your daily cleaning program takes about an hour. Each step uses chemicals and make-up water, creates wastewater to treat, and requires energy for heating, pumping, and recirculating the cleaning solution.

What if you could eliminate one or more steps?

ZwitterCo’s process RO elements are here to help you increase your bottom line.

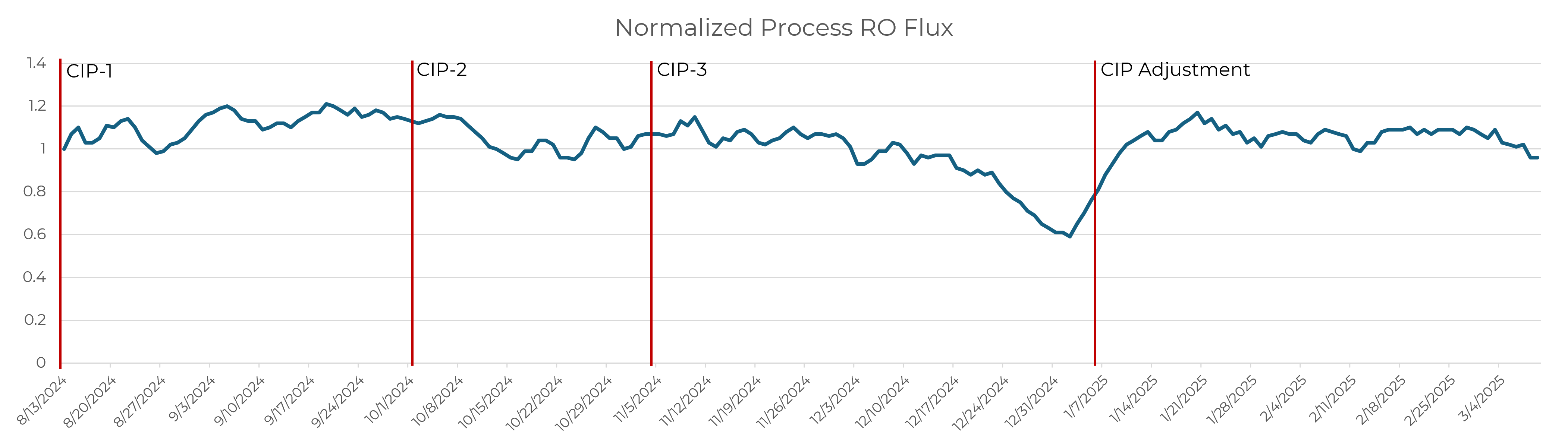

ZwitterCo RO polisher flux data collected over seven months post-installation.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

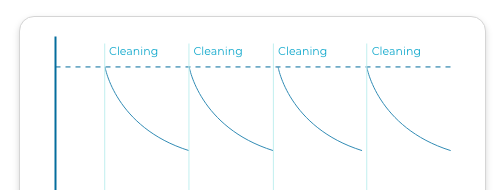

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

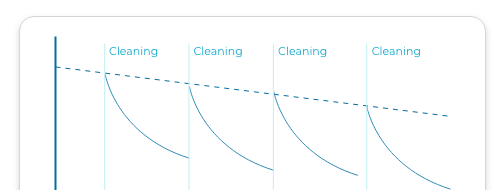

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance