ALL NEW FOULING-IMMUNE MEMBRANE TECHNOLOGY FOR

Manure Digestate

It’s time to upgrade your manure digestate management. ZwitterCo’s superfiltration (SF) membranes remove tough-to-treat compounds from digestate, allowing downstream reverse osmosis and nutrient recovery technologies to operate efficiently.

Edison Award

ZwitterCo superfiltration membranes received a Bronze award for innovation in the Water Treatment & Testing category at the 2024 Edison Awards.

This award highlights their impact on the meat and poultry industry, enabling > 99% removal of FOG and TSS.

Featured in US Poultry

Little Blurb about US Poultry Feature and a link to it.

Read More

Fouling-Immune Membrane Technology is Now Possible for Manure Digestate.

There are nearly as many on-farm anaerobic digestion projects being built today as in the past decade, yet only 5% of farm biogas potential is utilized, according to the American Biogas Council. While converting manure into biogas and RNG harnesses waste energy, managing liquid digestate can create challenges for permits, cost, and sustainability.

Sustainable digestate management and treatment systems built with ZwitterCo superfiltration (SF) membranes can help you:

- Reduce the costs and carbon intensity of operating your biogas facility

- Reduce waste hauling

- Lower emissions from land application

- Enable water reuse for irrigation or livestock

- Create organic fertilizer from recovered nutrients

ZwitterCo SF membranes were designed to process the toughest digestate streams, resolving disposal challenges and creating value from the leftover water and nutrients that remain beyond Renewable Natural Gas (RNG) production.

- High packing density

- Low pressure, low energy

- No back flushing

- Immune to irreversible fouling

- 1nm pore size

- Chlorine tolerant

Manure Digestate Solutions

What Challenges Can ZwitterCo Technology Solve For You?

MaximizeNutrient Recovery

ZwitterCo SF membranes integrated into a filtration system enable the efficient concentration of nitrogen and phosphorus, which creates the opportunity for saleable product from those excess nutrients.

EnhanceWater Recovery

ZwitterCo SF membranes when used as pretreatment for RO, achieve water recovery rates of 60-90% in harsh digestate applications, significantly reducing the volume of digestate needing to be stored or hauled.

EnsureContinuous Operations

Fouling-immune ZwitterCo SF membranes ensure stable and efficient digestate treatment, reducing risk of unplanned downtime and supporting compliance with nutrient management plans.

Minimize Hauling& Costs

ZwitterCo superfiltration membranes assist in efficiently separating water from digestate, significantly reducing volume and cutting transportation costs by minimizing off-site hauling

SOLUTION #1

Maximize Nutrient Recovery

Integrating ZwitterCo SF membranes significantly enhances nutrient recovery by removing 99% of suspended solids and organic foulants, allowing downstream technologies like RO to run more efficiently.

- Patented zwitterionic membrane is immune to irreversible fouling

- 1nm pore size produces TSS free permeate

- Filters out unwanted materials before RO processing

- Ensures only desired nutrients are concentrated

SOLUTION #2

Enhance Water Recovery

By efficiently filtering digestate, ZwitterCo SF membranes – when used as pretreatment for RO – achieve water recovery rates of 60-90%.

This enables water reuse for animals and significantly reduces the volume of digestate requiring storage or hauling, lowering costs and environmental harm.

SOLUTION #3

Ensure Continuous Operations

Digestate management and treatment systems built with our SF membranes offer:

- Full performance recovery after mild maintenance wash

- Minimal downtime with scheduled CIP

- 2 – 3 year expected membrane life

Fouling-immune ZwitterCo SF membranes ensure stable and efficient digestate treatment, reducing risk of unplanned downtime and supporting compliance with nutrient management plans.

WATER PURIFICATION

ZwitterCo Reverse Osmosis

ZwitterCo has integrated our patented zwitterionic technology with proven commercial brackish water membranes to deliver a drop-in replacement RO membrane with unprecedented fouling resistance.

ZwitterCo RO after MBR, tubular membranes, or to replace existing RO offers:

- Up to 90% reduced cleaning frequency

- 2x element life due to easier and quicker cleaning

- Effective concentration of essential nutrients for recovery and reuse

SOLUTION #4

Minimize Hauling & Costs

ZwitterCo superfiltration membranes assist in efficiently separating water from digestate, significantly reducing its volume.

This concentration process minimizes the amount of material that needs to be hauled off-site, leading to lower transportation costs and fewer hauling trips.

Additionally, the recovered water can be reused within the operation, further enhancing sustainability and cost-efficiency.

Save on Hauling

Fully integrated solutions featuring SF membranes have shown to reduce digestate hauling by 50-70%

APPLICATION BRIEF

Total Re-Haul of Manure Digestate Treatment

Land spreading regulations are becoming stricter and as a result, large volumes of digestate need to be hauled off-site. This is both costly and carbon intensive.

ZwitterCo SF membranes enable an economical, reliable, and sustainable transition away from hauling and pave a path to the future of digestate management.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

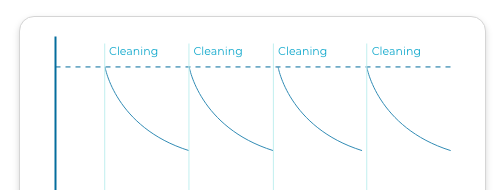

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

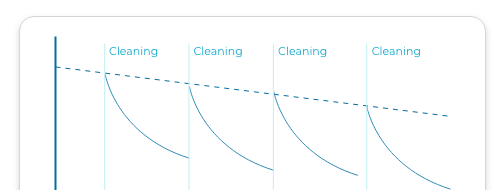

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance