ALL NEW FOULING-IMMUNE MEMBRANE TECHNOLOGY FOR

Bioprocessing

With ZwitterCo’s reliable and innovative membrane solutions, bioprocessors are able to achieve higher concentration factors and full performance recovery with a fast and easy cleanings.

Edison Award

ZwitterCo superfiltration membranes received a Bronze award for innovation in the Water Treatment & Testing category at the 2024 Edison Awards.

This award highlights their impact on the meat and poultry industry, enabling > 99% removal of FOG and TSS.

Featured in US Poultry

Little Blurb about US Poultry Feature and a link to it.

Read More

Fouling-Immune Membrane Technology is Finally Here for Bioprocessing.

The extraction of bio-manufactured compounds frequently requires complex, multi-step processes. Not only can these processes be expensive, but the resulting media losses and waste streams also can account for a substantial portion of the total manufacturing costs.

ZwitterCo has developed an award-winning, entirely new class of membrane technologies that solve the number one problem with membranes: fouling. Our zwitterionic technology is the foundation for fouling-resistant membranes that clean the most challenging wastewaters and surface waters – faster and easier than any membrane in history.

Bioprocessing Solutions

What Challenges Can ZwitterCo Technology Solve For You?

Downstream Processing

ZwitterCo membranes offer unprecedented fouling resistance, intrinsic pore uniformity, and permeance recovery. This results in higher product yield, increased throughput, longer uptime, and lower CIP costs.

Wastewater Treatment

With ZwitterCo SF membranes, you can achieve full performance recovery with fast and easy cleaning. This extends the membrane lifespan, reducing replacement frequency and overall costs.

SOLUTION #1

Optimize Downstream Processing

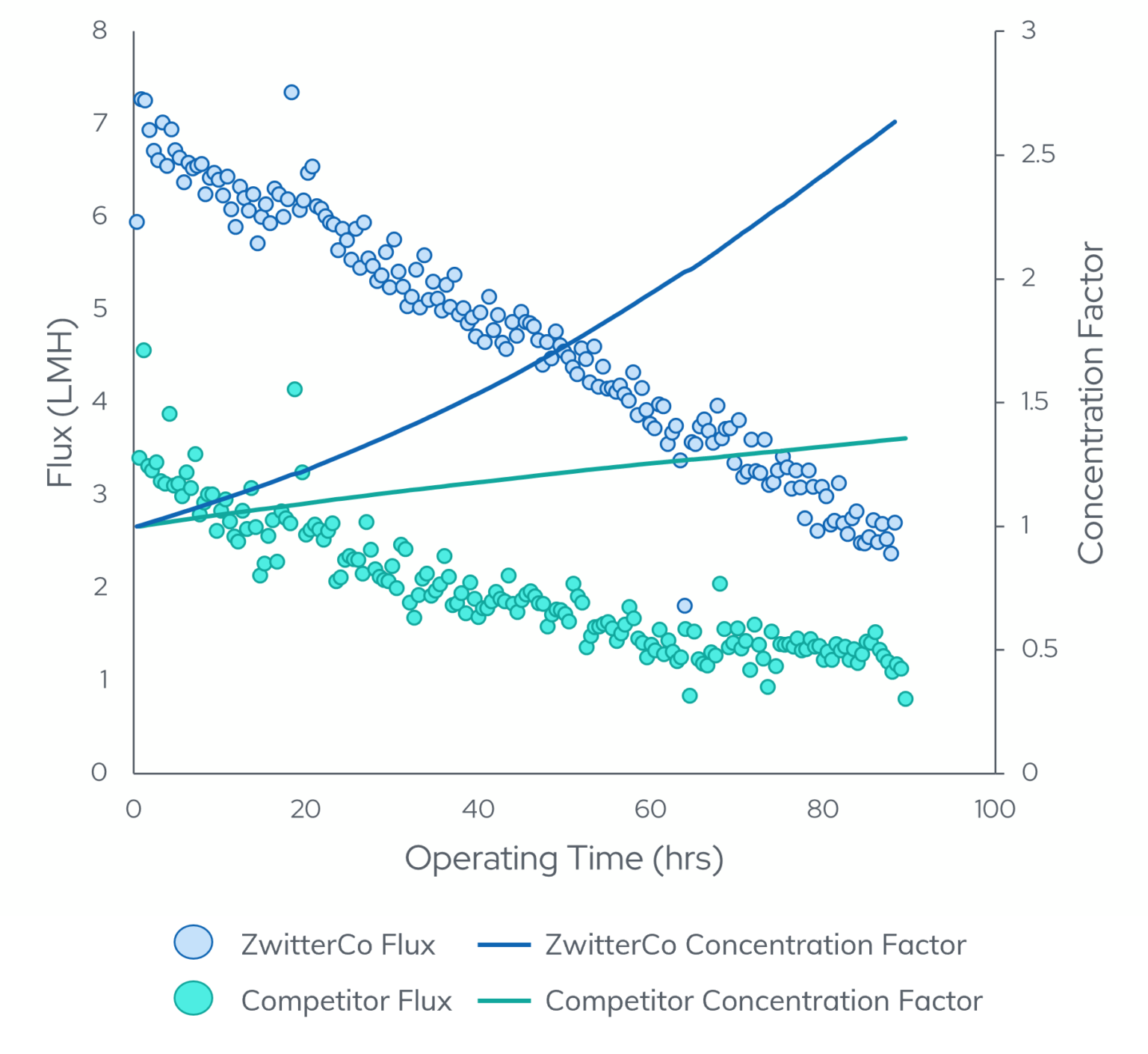

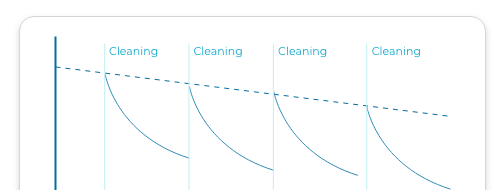

This graph is a side-by-side comparison of a ZwitterCo SF membrane with a competitor’s NF membrane

Run Longer Before Cleanings

ZwitterCo membranes operate at a more stable flux than conventional membranes, resulting in a higher average flux, allowing you to benefit from greater productivity and longer runs before cleaning.

This allows for more product from existing equipment, increasing overall productivity.

Easier & Less Frequent Cleanings

Whenever a cleaning is performed, valuable product is lost as it is flushed out of the system rather than recovered. But there is another option.

With ZwitterCo membranes, you achieve:

- Longer production runs

- Less frequent cleanings

- Higher product yield

- Full permeance recovery

Lower OPEX

ZwitterCo superfiltration membranes are immune to irreversible fouling, allowing for longer membrane life and less frequent membrane replacements – lowering overall OPEX.

ZwitterCo membranes also offer intrinsic pore uniformity and permeance recovery which results in:

- Higher product yield

- Increased throughput

- Longer uptime

- Lower CIP costs

This saves water and energy, allowing bioprocessors to develop more cost-effective and sustainable processes.

Easy Integration

ZwitterCo spiral membrane elements are designed to be drop-in replacements requiring no additional CAPEX. This seamless integration not only simplifies the upgrade process but also paves the way for future plant expansions and system scalability.

By choosing ZwitterCo, you can:

- Enhance your operations

- Increase capacity without disruptions to existing infrastructure

- Ensure smooth, uninterrupted growth

CASE STUDY

The Impact of ZwitterCo Membranes at Solugen

Dive into the details to see how we contributed to 400% savings in just 9 months and learn about the transformative impact of ZwitterCo’s solutions.

SOLUTION #2

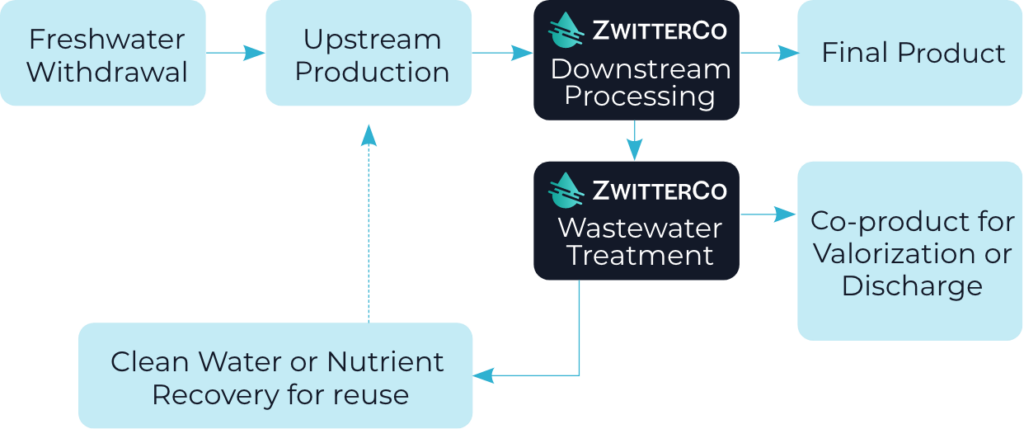

Advanced Wastewater Treatment

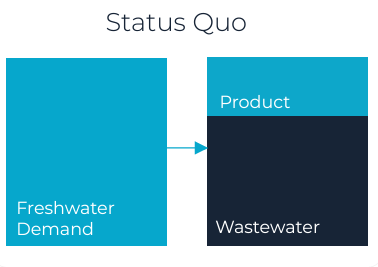

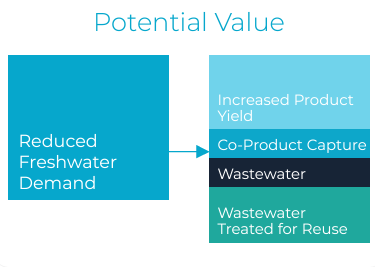

Reduce Freshwater Demand

ZwitterCo membranes enable water reuse to expand production without needing to access additional freshwater sources – maximizing the fermentation output of existing water supplies.

Ideal Pretreatment for RO

ZwitterCo membranes enhance downstream processing by increasing yields and throughput with exceptional fouling resistance, leading to sustainable bioprocessing with reduced water and energy use.

Transform Waste from Cost to Benefit

ZwitterCo membranes are beneficial for co-product creation and lost product capture during the wastewater treatment process, turning waste solids into potential revenue.

Reduce Volume of Wastewater Treated

Enhanced co-product capture enabled by ZwitterCo membranes, in combination with treating wastewater for reuse and reduced chemical use for cleanings, reduces freshwater demand and significantly decreases the total amount of waste generated by the bioprocessing plant.

“Our process would not be profitable or possible without ZwitterCo membranes.”

– Dr. Konrad Miller, VP, Manufacturing, Science, & Technology, Solugen

Reduce OPEX and Downtime

With ZwitterCo SF membranes, you can achieve full performance recovery with fast and easy cleaning. This extends the membrane lifespan, reducing replacement frequency and overall costs.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

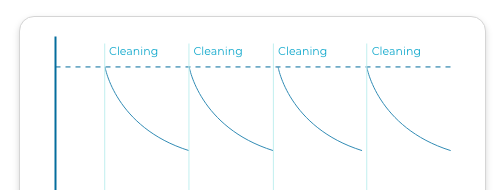

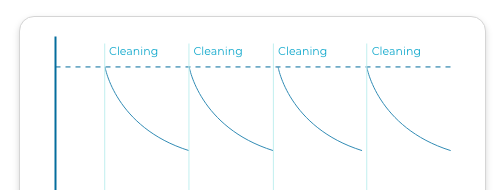

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

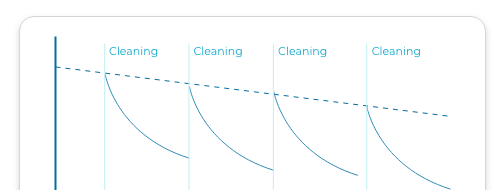

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

No wear and tear

Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

Short lifespans from degradation

Compromised performance