30-50x Tighter Pore Size

ZwitterCo membranes have a 30-50x tighter pore size which produces ideal feed quality for nutrient concentration.

High Performance

ZwitterCo membranes stand out in digestate treatment due to their patented zwitterionic layer that prevents irreversible fouling, enabling effective processing with minimal maintenance and lower operational costs.

Low Energy

ZwitterCo superfiltration membranes, with their spiral configuration, offer higher packing density and significantly lower energy consumption compared to tubular membranes in digestate applications.

The Demand for Low Energy Membranes

The European Biogas Association estimates that there are nearly 20,000 biogas facilities that produce 180 million tonnes of digestate annually.

With regulations such as the EU Nitrates Directive restricting the ability to spread digestate, proper nutrient management is paramount for any new biogas project. Membrane technologies such as microfiltration and ultrafiltration have gained popularity due to their ability to concentrate nutrients, reduce the volume of digestate needed to be hauled off-site, and ultimately improve the OPEX required to process digestate.

However, the tubular membrane configurations that are common in digestate processing carry heavy energy requirements. Between 2018 and 2022, the price of electricity for non-household consumers in the EU increased nearly 80% from €0.14 to €0.25. As a result, there is a growing demand for membrane technologies that require significantly less energy demand.

To address this, ZwitterCo Z-Clear™ superfiltration membranes offer a low-energy alternative that achieves ideal digestate filtration and concentration targets.

Filter out fat

to make clean water

from every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

ZwitterCo Superfiltration Membrane Spec Sheets

ZwitterCo Superfiltration

A Paradigm Shift in Membranes

Superfiltration membranes are a new separation class between ultrafiltration and nanofiltration. ZwitterCo superfiltration membranes deliver unprecedented fouling resistance, low energy requirements, wide pH tolerance, and the ability to be cleaned with chlorine.

Superfiltration membranes are designed for fractionating dissolved components, like capturing protein while passing inorganic molecules. Our membranes are engineered tightly enough to remove fats, oils, grease (FOG), and high-strength organics, providing ideal pre-treatment for reverse osmosis in wastewater.

Contact us today.

Learn about the technology.

Reimagine Nutrient Recovery with ZwitterCo Superfiltration

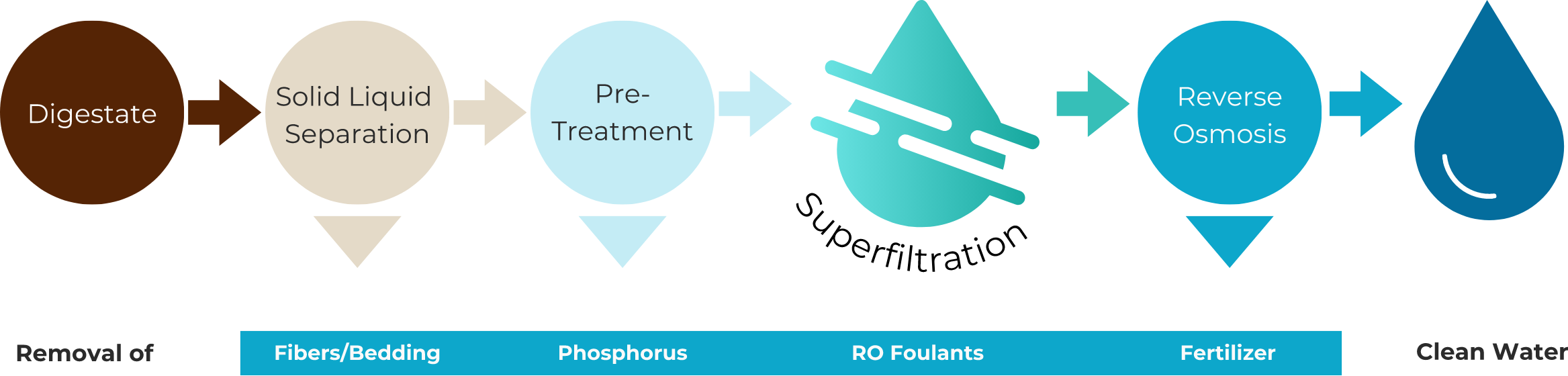

To support the European Commission’s steps to lessen the dependency on chemical fertilizer imports, ZwitterCo superfiltration membranes play a key role in nutrient concentration systems that produce local, organic fertilizers from manure and food waste digestate.

After solid-liquid separation, Z-Clear™ SF membranes serve as an ideal pre-treatment to reverse osmosis by removing suspended solids and large dissolved organic compounds, generating a turbidity-free permeate with minimal loss of nutrients.

The nutrients can then be efficiently extracted via ammonia stripping, distillation, reverse osmosis, and other polishing technologies to create a saleable, nutrient-rich liquid or solid product.

200m3/day Manure Digestate Application

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

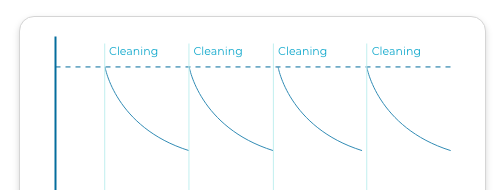

No wear and tear

Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

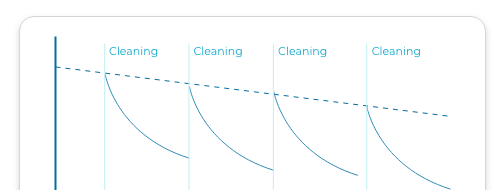

Short lifespans from degradation

Compromised performance