RO MEMBRANES WITH FOULING-IMMUNE TECHNOLOGY FOR

Food & Beverage

With ZwitterCo membranes, it’s time for a new era for food and beverage water treatment. ZwitterCo’s advanced drop-in replacement RO membranes use fouling-immune technology to reduce cleaning frequency by up to 90% and last at least 2x longer than conventional RO membranes.

Edison Award

ZwitterCo superfiltration membranes received a Bronze award for innovation in the Water Treatment & Testing category at the 2024 Edison Awards.

This award highlights their impact on the meat and poultry industry, enabling > 99% removal of FOG and TSS.

Featured in US Poultry

Little Blurb about US Poultry Feature and a link to it.

Read More

Fouling-Immune Membrane Technology is Now Possible for Food & Beverage.

Food & beverage wastewater is packed with organics (BOD/COD), nutrients, and suspended solids, making discharge regulations or sustainability goals challenging. Primary and secondary treatment processes handle solids and organics, while RO membranes polish tertiary water by removing remaining contaminants. However, conventional BWRO membranes are often subject to fouling due to the dissolved organics that pass through upstream biological treatment. This leads to system performance challenges, increased chemical cleanings, downtime, and shorter membrane lifespans.

ZwitterCo has developed an award-winning, entirely new class of membrane technology that solves the number one problem with membranes: organic fouling. Being built with fouling-immune technology, ZwitterCo membranes enable lower operating costs by reducing system downtime and maintenance from fouling.

ZwitterCo has integrated our patented zwitterionic technology with proven commercial brackish water membranes to deliver a drop-in replacement RO membrane with unprecedented fouling resistance.

- Longer membrane life

- Reduced operating costs

- Significantly longer run-time between required maintenance

- Full performance restoration

Food & Beverage

What Challenges Can ZwitterCo Technology Solve For You?

ReduceFrequent Cleaning

ZwitterCo RO is perfect for existing RO systems treating food & beverage wastewater that are struggling with frequent high pH cleaning.

ReduceOPEX

With up to a 90% reduction in cleaning frequency, element lifespan is increased and in turn, element replacements are less frequent, saving time and money.

MeetDischarge Requirements

ZwitterCo RO helps food & beverage processors meet tightening discharge requirements in a cost-effective manner with less maintenance and reduced OPEX compared to conventional RO.

Achieve WaterReuse Targets

ZwitterCo RO not only enables users to better meet their sustainability targets by treating and reusing wastewater streams, but it also enables users to benefit from reduced cleaning frequency and longer element life.

SOLUTION #1

Reduce Frequent Cleaning

ZwitterCo RO is perfect for existing RO systems treating food & beverage wastewater that are struggling with frequent high pH cleaning.

Built using fouling-immune technology, our advanced drop-in replacement RO membranes:

- Reduce cleaning frequency by up to 90%

- Offer 2x membrane lifespan

- Lower overall costs

SOLUTION #2

Reduced OPEX

Excessive cleaning shortens the membrane lifespan.

With up to a 90% reduction in cleaning frequency, element lifespan is increased and in turn, element replacements are less frequent, saving time and money.

SOLUTION #3

Meet Tightening Discharge Requirements

Tightening local discharge regulations on BOD/COD, nutrients, synthetic organics, and dissolved solids is pushing the need for additional wastewater treatment or polishing steps utilizing RO.

ZwitterCo RO offers:

- Cost-effective solutions for meeting tighter discharge requirements

- Unmatched fouling resistance for reliable, high-quality treatment

- Reduced OPEX and less maintenance compared to conventional RO systems

IDEAL RO PRETREATMENT

ZwitterCo Superfiltration (SF)

ZwitterCo SF is the ideal pretreatment for RO systems, reducing contaminants that cause poor system performance.

ZwitterCo superfiltration as pretreatment for RO offers:

- 90-99% removal of TSS

- 90-99% removal of FOG

- 30-90% removal of COD/BOD

SOLUTION #4

Achieve Water Reuse & Sustainability Targets

Pervasive 2030 green initiatives and water reduction targets require advanced treatment and are driving industry-wide changes in water management.

ZwitterCo RO not only enables users to better meet their sustainability targets by treating and reusing wastewater streams, but it also enables users to benefit from reduced cleaning frequency and longer element life, reducing chemical waste and element waste.

- Reduce chemical waste

- Extend membrane lifespan

- Reduce freshwater dependency

FREE EBOOK

Maximizing Water Reuse: Advanced RO Membranes in Food & Beverage

Reduce operating costs by switching to ZwitterCo RO

Are you cleaning your membranes once a month or more frequently and replacing them every 2 years or less? Now, you don’t have to. Download our free eBook to learn how companies are turning to new, fouling-immune membrane technology to save time and money.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

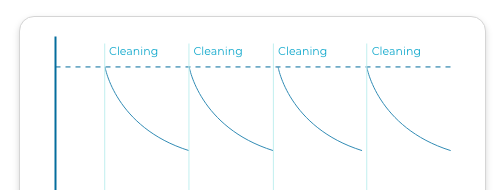

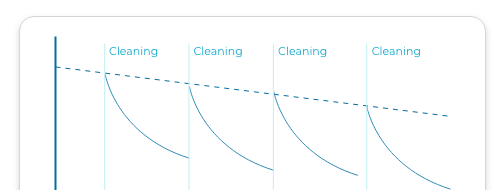

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

Learn About Our First Install Discounts

- Do you have issues with biofouling or organic fouling?

- Are you cleaning at least once a month?

- Are you replacing your membranes every 2 years or less?

Put ZwitterCo RO to the test against your fouling-resistant membranes.

With our first install discount, you will receive:

- Special pricing and terms

- Tier 1 technical and operational support

- Direct access to our product team