RO MEMBRANES WITH FOULING-IMMUNE TECHNOLOGY FOR

Landfill Leachate

With ZwitterCo membranes, it's time for a new era for landfill leachate management. ZwitterCo’s advanced drop-in replacement RO membranes use fouling-immune technology to reduce cleaning frequency by up to 90% and last at least 2x longer than conventional RO membranes.

Fouling-Immune Membrane Technology is Now Possible for Landfill Leachate.

Because landfill leachate often has high levels of organic material (like TOC, COD, or BOD), the first pass RO membranes in two-pass systems regularly suffer from organic fouling. This means the membranes may need to be cleaned every few days and fully replaced every six-to-twelve months. This frequent maintenance is not only costly but also time-consuming, preventing operators from focusing on other critical tasks.

ZwitterCo has developed an award-winning, entirely new class of membrane technologies that solve the number one problem with membranes: fouling. Being built with fouling-immune technology, ZwitterCo membranes are able to lower costs associated with frequent fouling.

ZwitterCo has integrated our patented zwitterionic technology with proven commercial brackish water membranes to deliver a drop-in replacement RO membrane with unprecedented fouling resistance.

- Longer membrane life

- Reduced operating costs

- Significantly longer run-time between required maintenance

- Full performance restoration

Landfill Leachate Solutions

What Challenges Can ZwitterCo Technology Solve For You?

ReduceOPEX

Cleaning kills membranes. With up to a 90% reduction in cleaning frequency, element replacements are less frequent, saving time and money.

IncreasedUptime

No more system upsets or headaches due to fouling and membrane cleaning. Stable operation with minimal cleaning allows for increased uptime, so you can focus on the important things.

Reduce or Eliminate Irreversible Fouling

ZwitterCo has integrated our patented zwitterionic technology with proven commercial brackish water membranes to deliver unprecedented fouling resistance, reducing cleaning and membrane replacement frequency.

PromoteSustainability

By reducing the volume of waste generated from frequent membrane cleanings and replacements, ZwitterCo membranes contribute to more sustainable landfill operations.

SOLUTION #1

Reduce OPEX

Our advanced drop-in replacement RO membranes offer 2x membrane life and reduce cleaning frequency by up to 90%. This allows for fewer element replacements and less chemical usage, providing significant overall cost savings.

- Drop-in replacement - No CAPEX

- 2x membrane life

- Reduced cleaning frequency

"Overall, we’re thrilled with how things are going. Less chemicals, longer run times, and an easier process for our team—it’s been a win all around"

– SERPOL, France

SOLUTION #2

Reduced Downtime From Cleaning

Operators want to focus on other tasks without the hassle of frequent maintenance on the water treatment system.

With ZwitterCo RO membranes that use fouling-immune technology, cleaning frequency is reduced by up to 90%, allowing for more uptime and more water treated to empty holding ponds/tanks.

Cost Savings

A landfill leachate treatment system using 30 x 8040 RO elements could reduce annual cleaning costs by over $1,500 per element when switching to ZwitterCo RO.

SOLUTION #3

Reduce or Eliminate Fouling Issues

High organic content in leachate often fouls the first pass of a multi-pass RO system. This means RO membranes may need to be cleaned as often as every few days and fully replaced every 6-12 months.

ZwitterCo has integrated our patented zwitterionic technology with proven commercial brackish water membranes to solve these challenges and deliver unprecedented fouling resistance. This reduces cleaning frequency and in turn, membrane replacement frequency.

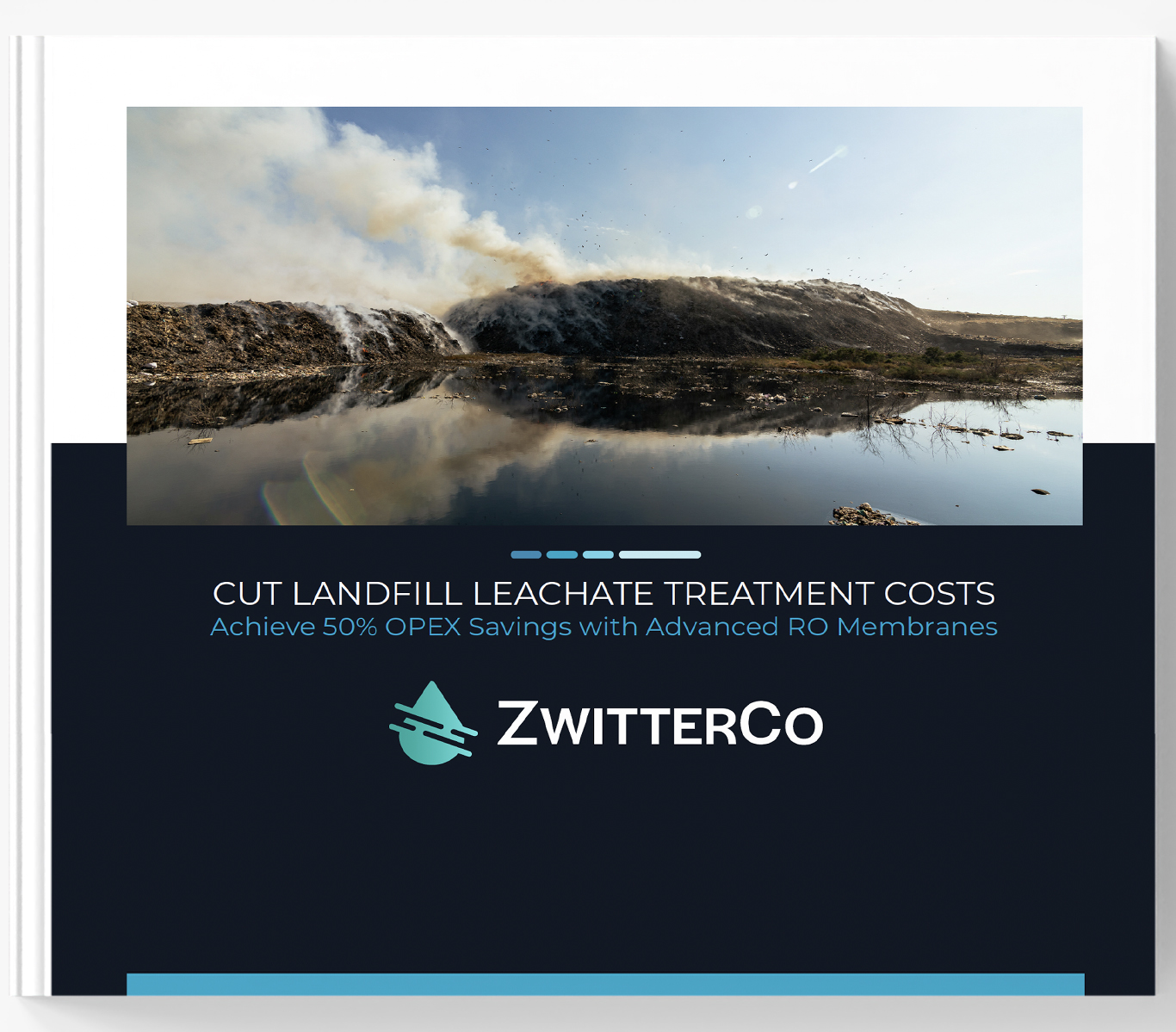

FREE EBOOKCut Landfill Leachate Treatment Costs

Achieve 50% OPEX Savings with Advanced RO Membranes

Are you cleaning your membranes every few days and replacing them every 6-12 months? Now, you don’t have to. Download our free eBook to learn how companies are turning to new, fouling-immune membrane technology to save time and money.

IDEAL RO PRETREATMENT

ZwitterCo Superfiltration (SF)

ZwitterCo SF in leachate provides TSS and FOG free permeate that is ideal for RO or deep well injection.

ZwitterCo superfiltration as pretreatment for RO offers:

- 90-99% removal of TSS

- 90-99% removal of FOG

- 30-90% removal of COD/BOD

- Reduction of hauling volumes by up to 80%

SOLUTION #4

Promote Sustainability

By reducing the volume of waste generated from frequent membrane cleanings and replacements, ZwitterCo membranes play a key role in contributing to more sustainable landfill operations.

Plus, according to the EPA, reverse osmosis membranes – like ZwitterCo’s – can remove up to 99% of certain PFAS, making them a strong choice for protecting the environment.

With reduced cleaning frequency, ZwitterCo membranes also

- Reduce chemical use

- Reduce freshwater dependency

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

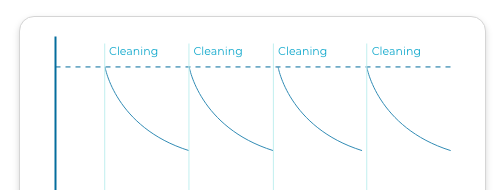

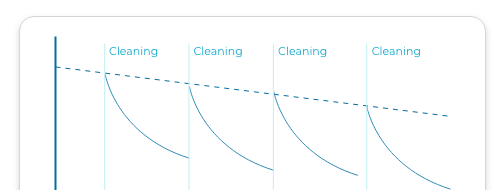

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

Learn About Our First Install Discounts

- Do you have issues with biofouling or organic fouling?

- Are you cleaning at least once a month?

- Are you replacing your membranes every 2 years or less?

Put ZwitterCo RO to the test against your fouling-resistant membranes.

With our first install discount, you will receive:

- Special pricing and terms

- Tier 1 technical and operational support

- Direct access to our product team