Longer Element Life

Cleaning kills membranes. Minimal chemical use ensures stable rejection performance for years. ZwitterCo RO will help you meet your permeate quality targets.

Better Plant Operation

No more system upsets or headaches due to fouling. Stable operation with minimal downtime allows you to meet your production volume targets.

SaveMoney

With ZwitterCo RO membranes, enjoy less downtime, fewer cleanings, decreased chemical usage, and significantly reduced waste water hauling.

Restore Performance

Biology and other organic material cannot stick to and grow on the zwitterionic membrane surface, and cleaning will easily restore performance.

Reimagine your RO Elements

ZwitterCo Reverse Osmosis elements come in industry-standard sizes, just like you’re used to. No new equipment or system modifications are required to implement this technology. Simply install it and operate it like you would any other RO – but it performs better and requires less maintenance.

Filter out fat

to make clean water

from every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

ZwitterCo Reverse Osmosis

A Paradigm Shift in Membranes

ZwitterCo developed the industry’s first brackish water reverse osmosis membranes to use zwitterionic technology to deliver unprecedented fouling resistance. Our reverse osmosis elements offer the most stable performance on high-fouling streams and can be fully restored with either a water flush or a mild cleaning, resulting in at least twice the membrane life.

ZwitterCo RO is designed to replace traditional reverse osmosis membranes that are struggling with biofouling or organic fouling from surface water or wastewater feed sources. A simple drop-in replacement can lower operating costs and cleaning frequency by up to 90% and allow systems to operate at maximum capacity with minimal downtime.

Learn more about our unique zwitterionic membranes.

ZwitterCo RO Element Data Sheets

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

RO Success Story

The Challenge

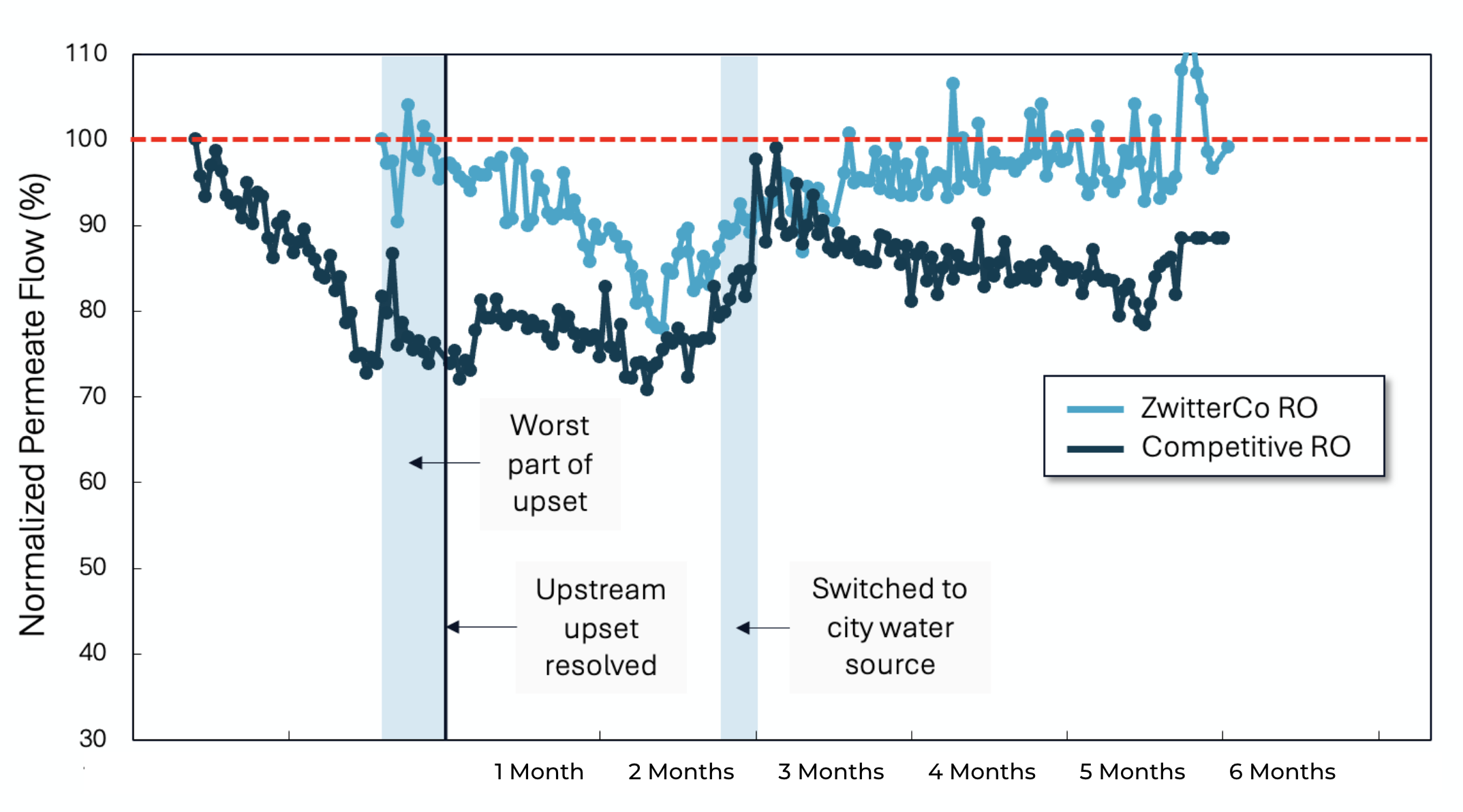

A power plant in the Pacific Northwest of the United States treating river water for boiler makeup is confronting ongoing issues with frequent maintenance and downtime. Despite installing conventional fouling-resistant reverse osmosis elements, this plant averages chemical cleanings at least once a month due to persistent organic fouling challenges. Additionally, the RO elements undergo replacement every 12 to 18 months when they fail to meet the plant’s performance standards. This cycle of high cleaning frequency and element replacement has led the plant to seek a new solution.

ZwitterCo RO Membrane Success

After over 5 months of operation at a power plant in the Pacific Northwest, ZwitterCo Low Energy RO elements have demonstrated more stable performance without requiring cleaning. In fact, they are consistently operating at 10% higher normalized permeate flow than competitive elements…even after being exposed to an upstream upset!

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

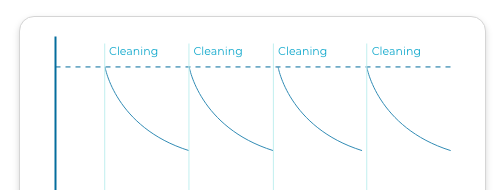

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

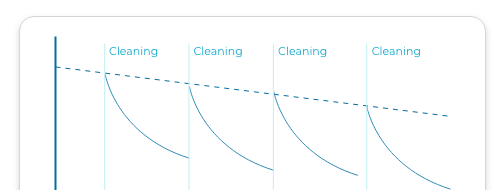

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

Learn More About Our First Install Discounts

- Do you have issues with biofouling or organic fouling?

- Are you cleaning at least once a month?

- Are you replacing your membranes every 2 years or less?

Put ZwitterCo RO to the test against your fouling-resistant membranes.

With our first install discount, you will receive:

- Special pricing and terms

- Tier 1 technical and operational support

- Direct access to our product team