Filter out fat

to make clean water

from every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

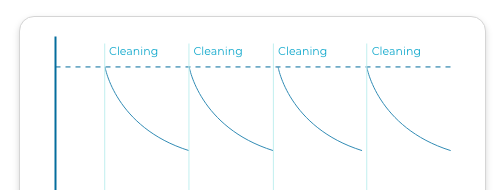

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

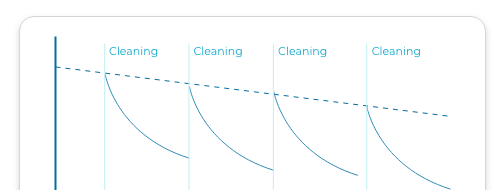

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

How Many Steps in a “Four-Step” Membrane CIP?

Seems like a silly question. Or a riddle. But when the flushing steps are counted, typical membrane cleaning programs become 11 steps or more. That’s a lot of water and wastewater to treat.

Sustainability…At Lower Cost

ZwitterCo is now implementing our fouling-immune technology and designing sanitary products specific for food, dairy, and beverage processes that enable a daily 1-step clean plus sanitization.

A simple drop-in replacement will cut cleaning costs by >50% by reducing chemicals, make-up water, wastewater, and energy. Additionally, chlorine is not required to restore membrane performance.

Use ZwitterCo’s economic savings tools to model the potential savings in your systems. Download today!

Benefits of ZwitterCo Membranes

Reduce OPEX

Lower chemical costs, reduced wastewater costs, and less energy required.

Sustainability

Less water required, decrease chemical usage, and clean without chlorine.

No CAPEX Required

A simple drop-in replacement can lower operating costs and cleaning frequency by up to 90%

Case Study

How ZwitterCo's Membranes Solved Multiple Challenges for Solugen

With ZwitterCo membranes, achieve higher concentration factors and full performance recovery with fast and easy cleaning.