Do you know how much you’re really spending on cleaning your RO system?

The costs might be higher than you think.

When it comes to RO membranes, understanding the true costs of membrane cleaning may seem crucial for cost-effective operations, yet many are surprisingly unaware of all the associated expenses. While the cost of cleaning chemicals can be easily tracked, the additional costs associated with cleaning and the bigger picture of how frequent chemical cleanings affect overall system performance can often be overlooked.

Frequent membrane cleaning, while necessary to maintain system performance, tends to heavily increase overall expenses. To make informed decisions for your plant operations, knowing the details of what membrane cleaning is costing you is key.

The Direct Costs

As mentioned above, most people are unaware of the true costs of membrane cleaning. It’s not just the cost of cleaning chemicals that raises expenses; the overall impact of the cleaning itself, especially if you are cleaning frequently, can escalate into bigger-picture issues, significantly increasing OPEX.

Downtime Costs

Downtime costs from membrane cleaning can detrimentally impact operations, as each cleaning cycle requires a temporary system shutdown. This pause in production may impact downstream processes and lead to considerable revenue losses.

Unplanned Downtime

System upsets can also worsen these issues, resulting in additional or longer periods of downtime and higher operational costs. It’s important to consider these factors – not only when evaluating cleaning expenses, but overall operational costs as well.

Chemical Expenses

Cleaning chemical expenses can add up quickly. The industry average for formulated cleaners is roughly $43 per cleaning, per element. The more you clean, the more cleaning chemicals you need, driving up your costs. Cleaning chemicals also shorten membrane lifespan and have a negative environmental impact. Using fewer chemicals not only extends membrane life but also promotes sustainability.

Labor Costs

Labor costs for membrane cleaning can quickly escalate in various ways. While most plants have a set number of operators on their payroll, frequent cleaning can pull these operators away from their regular duties. This can lead to inefficiencies and a need to hire additional operators or pay overtime to manage the cleaning workload.

In some cases, plants may even send elements offsite for cleaning services, adding to the overall expenses. The more often you clean, the higher these costs climb, so it’s crucial to think about both the short-term and long-term impacts on your budget.

Energy Costs

To ensure an effective cleaning, the cleaning solution is often heated before it enters the system. While the energy used to heat and pump the cleaning solution through the system are often smaller costs, they are additional costs associated with cleaning. The more frequently cleanings are performed, the more these costs impact overall operation.

Waste Disposal

Each time a cleaning is performed, waste is generated. Spent chemicals and dirty flush water are purged from the system. This waste is often discharged or hauled offsite for further treatment – both of which can incur additional costs.

Fresh Water

Cleaning solutions require make-up water that is RO permeate quality or similar. Depending on where the site gets its make-up water, this may be another cost to consider. For example, some sites purchase water from the local water authority or municipality, and the more frequently they clean, the more they’re spending on obtaining fresh water for those cleanings.

The Hidden Costs

Frequent cleanings might seem like the best way to keep your membranes in top shape, but they come with hidden costs that can sneak up on you.

Frequent Membrane Replacements

Every cleaning cycle chips away at the lifespan of your membranes, requiring you to replace your membranes more often. This not only increases replacement costs but also contributes to additional downtime associated with installing and commissioning new membranes.

Installation Costs

Replacing membranes isn’t just about buying new ones. There’s also the cost of installation and setup. Each time you need to install new membranes, you’re spending on labor and resources to get everything up and running again.

Downtime due to Installations

Frequent membrane replacements are not only costly but also require system downtime to replace the old membranes. This downtime disrupts operations and leads to lost productivity, resulting in substantial additional expenses.

The Operational Impacts

In addition to increasing expenses and downtime, frequent membrane cleaning can have significant operational impacts that severely affect a plant’s performance.

Lost Productivity

Each time your system goes offline for a cleaning cycle, it’s not producing purified water, which translates directly to lost productivity. Frequent periods of system downtime make it more difficult to meet production volume targets, impacting downstream processes and your bottom line.

While cleaning and downtime can’t be entirely avoided, new membrane technology has advanced to offer membranes that require less cleaning, saving you money and time.

Reduced Permeate Quality

Chemicals kill membranes. Chemical cleaning causes conventional RO membranes to lose rejection over time as the chemicals slowly deteriorate the membrane. Frequent cleaning accelerates membrane deterioration, resulting in a faster performance decline, usually seen by a noticeable increase in salt passage. When permeate quality targets are no longer met, downstream processes may suffer and require additional maintenance, increasing operating costs.

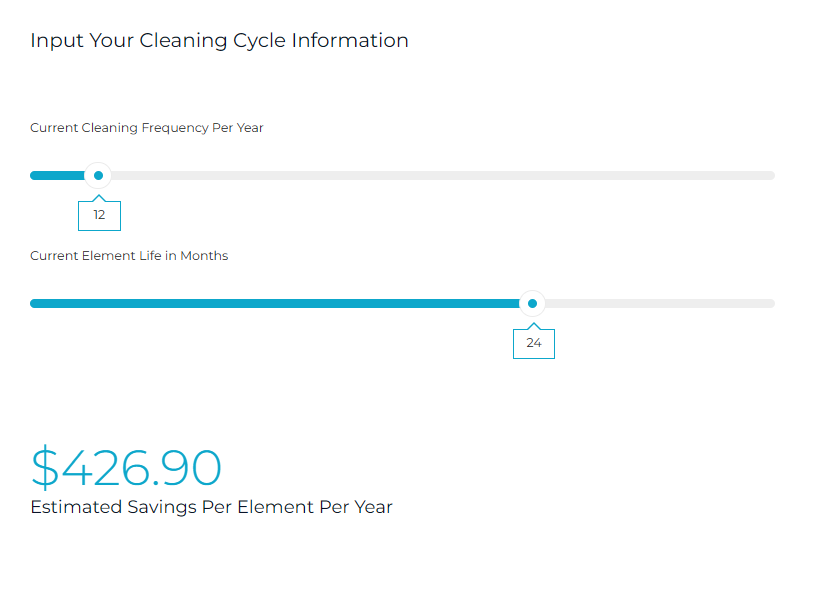

Membrane Savings Calculator

Curious about how much you could save on RO membrane cleaning? With advanced membrane technology, you could benefit from up to 90% less frequent cleaning and at least twice the membrane life.

Our Savings Calculator is designed to give you an instant estimate of how much you could save per element, per year when using ZwitterCo RO. Click here to get your instant estimate today.

Designed to be a drop-in replacement, ZwitterCo RO offers a no-risk opportunity for users to upgrade their system and lower costs without additional CAPEX.

Click here to learn more.

Cutting down on cleaning costs can be achieved with a balance of smart practices and the latest membrane tech. By fine-tuning your operations and sticking to a good maintenance schedule, you can reduce how often and how intensely you need to clean.

Newer membrane technologies are a game-changer—requiring less frequent cleaning and lasting longer, saving you money in the long run. It’s important to know all the costs involved in membrane cleaning, from chemicals and labor to hidden costs like downtime, to make the most informed decisions for your plant.