BeneficialReuse

ZwitterCo’s membranes enable cost-effective desalination processes, generating water that is eligible for reuse outside of the oilfield.

Improve Residual Hydrocarbon Yield

Membranes provide a chemical-free concentration of residual hydrocarbons.

Low Maintenance & Chemical Demand

Our membranes can be cleaned and maintained via remote automation, using generic cleaning chemicals.

Maximize Sustainability

Less freshwater drawdown and lower hauling emissions from more efficient produced water management.

Finding a Solution for Produced Water

With over 10 billion gallons of produced water generated per day globally, improving the water footprint of oil and gas operations could have an immense impact on water and energy security.

ZwitterCo provides a core technology within the world’s leading integrated solutions for treating produced water.

As a winner of the Department of Energy’s Water Security Grand Challenge Grant, ZwitterCo demonstrated that an integrated produced water treatment process capable of achieving beneficial reuse-quality effluent could be commercially deployed for less than the cost of traditional hauling and disposal via deep well injection.

Increase producedwater reuse outside the oilfield.

The ZwitterCo superfiltration membranes extract hydrocarbons and residual fine solids from produced water, including larger dissolved compounds, producing a clean stream easily polished with downstream desalination or brine concentration technologies.

- Food Crop Irrigation

- Non-Food Crop Irrigation

- Groundwater Augmentation

- River Augmentation

- Industrial Demand Centers

ZwitterCo Superfiltration Membrane Spec Sheets

ZwitterCo Superfiltration

A Paradigm Shift in Membranes

Superfiltration membranes are a new separation class between ultrafiltration and nanofiltration. ZwitterCo superfiltration membranes deliver unprecedented fouling resistance, low energy requirements, wide pH tolerance, and the ability to be cleaned with chlorine.

Superfiltration membranes are designed for fractionating dissolved components, like capturing protein while passing inorganic molecules. Our membranes are engineered tightly enough to remove fats, oils, grease (FOG), and high-strength organics, providing ideal pre-treatment for reverse osmosis in wastewater.

Contact us today.

Learn about the technology.

The Benefits of ZwitterCo

Increase Produced Water Reuse Outside the Oilfield

For applications like food and non-food crop irrigation, river and groundwater augmentation, or other industrial demand centers (i.e., cooling tower or boiler feed makeup) reuse outside the oilfield is now possible.

Our superfiltration membrane uniquely improves pre-treatment for desalination tools in produced water, removing all suspended solids, emulsified oils, and more significant dissolved organic compounds.

The clean superfiltration permeate stream only has salts and low molecular weight compounds that do not present a fouling risk for brine concentration technologies.

Improve Residual Hydrocarbon Yields

Superfiltration membranes provide a chemical-free concentration of residual hydrocarbons not captured in the upstream oil-water separations process, which can boost product yields. Achieving higher efficiencies in hydrocarbon extraction also makes the resulting permeate easier to discharge or reuse.

Reduce Maintenance and Chemical Usage

Using automated, remote cleaning procedures, superfiltration membranes can be cleaned and maintained at ambient temperatures. Cleaning solutions only require generic, low-cost cleaning chemicals that would be present at any oilfield site, and the membranes last for years before needing replacement.

Filter out fat

to make clean waterfrom every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

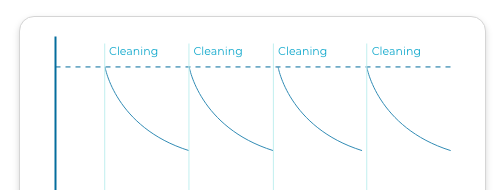

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

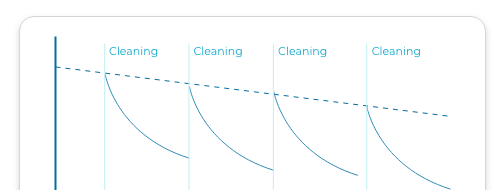

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

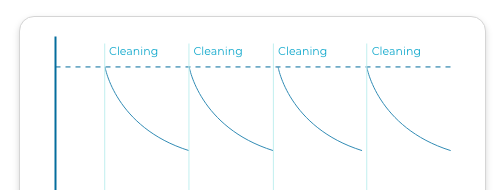

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

No wear and tear

Reliable treatment quality

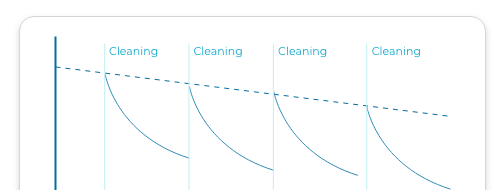

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

Short lifespans from degradation

Compromised performance