Avoid Surcharges & Site Violations

ZwitterCo membranes can meet discharge limits based on suspended solids or FOG concentration levels.

Reduce Costly Wastewater Hauling

Integrating superfiltration and reverse osmosis can reduce wastewater hauling volumes by 50% or more.

Reduce Expensive Chemistry

Eliminate coagulant or polymer loading from dissolved air flotation treatment.

Small Footprint Maximizes Capacity

Membrane processes are some of the most space-saving and footprint-flexible unit operations.

The Problem in Dairy Wastewater Treatment

Dairy plants often use biological or chemical-based solutions for their wastewater because the high levels of fats, oils, and grease (FOG) and other solids can overwhelm traditional filtration. But these technologies have their challenges.

Biological installations require extensive buildouts, are prone to upsets, and are not viable for facilities with space constraints. Chemical processes, typically paired with dissolved air flotation (DAF) technology, can produce poor or irregular effluent quality and need expensive, daily chemical use.

A New Era forDairy Wastewater Reuse

To solve the conventional limitations of filtration, ZwitterCo has engineered membranes that are immune to organic fouling and capable of reliably processing streams that are rich with FOG and protein.

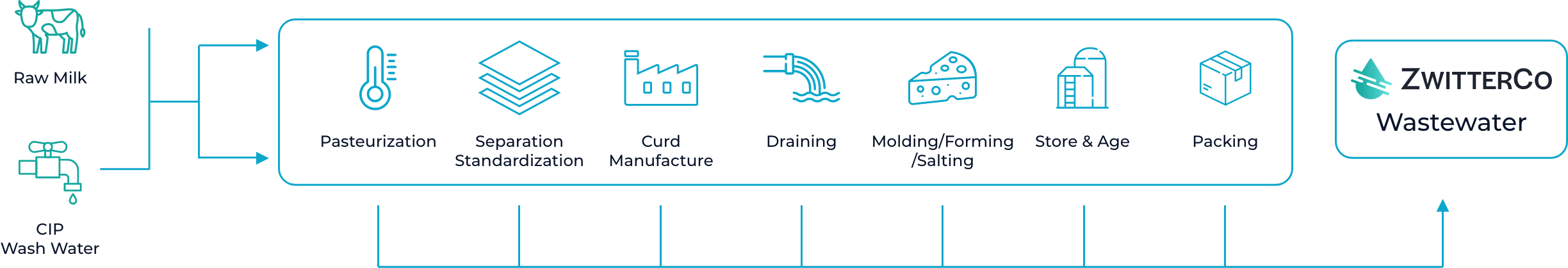

This chart shows multiple operations and CIP steps within a dairy processing facility that can create high-strength wastewater. ZwitterCo membranes enable treating to discharge or reuse limits.

The Benefits of ZwitterCo

Reliable Treatment Without In-Line Chemical Addition

Our superfiltration membranes offer a permanent barrier to retain contaminants. They deliver more reliable effluent quality than DAF technologies, which need regular adjustment in aeration, residence time, and chemical loading to keep up with variable wastewater characteristics.

With a membrane-based approach, dairy plants can:

- Experience significant operational savings

- Eliminate coagulant or polymer loading in their wastewater

- Convert chemical sludge hauling to chemical-free concentrate removal

Avoid Surcharges, Site Violations, or Public Concerns

With their unprecedented fouling resistance, ZwitterCo superfiltration membranes can completely remove total suspended solids (TSS) and FOG from high-strength wastewater without compromising the membrane’s performance, lifespan, or ease of maintenance.

Final polishing with ZwitterCo reverse osmosis (RO) can reduce well below discharge limits:

- Biological oxygen demand (BOD)

- Chemical oxygen demand (COD)

- Total dissolved solids (TDS)

Haul Less and Reduce Costs

Off-site wastewater hauling has been a part of the global wastewater equation for decades, but it can be reduced or eliminated. High-strength wastewater is still mostly water and is heavy, costly, and inefficient to haul. Integrated filtration solutions using our superfiltration membranes and reverse osmosis can reduce hauling volumes by >60%, taking trucks off the road and immediately yielding operational savings.

Superfiltration membranes and reverse osmosis can:

- Reduce hauling volumes by >60%

- Take trucks off the road

- Immediately yield operational savings

Save Space and Improve Site Management

Biological treatment systems take up significant space and are not always viable in the urban environments where many dairy processors are located. Filtration solutions using ZwitterCo’s membranes are some of the most space-saving and “footprint-flexible” treatment options available.

Our membrane systems can also be entirely fabricated offsite. No more:

- Outward expansion with high, upfront capital costs

- Long, onsite construction jobs

Achieve Sustainability Goals

Filtration solutions using our superfiltration membranes can generate reuse-quality water for washing trucks, tanks, or floors, or for boiler feed or cooling tower makeup.

Recycling polished wastewater can:

- Reduce your plant water footprint

- Help you achieve annual water-reduction goals

Filter out fat

to make clean waterfrom every source.

Introducing the world’s only membranes engineered to create clean water from high fouling environments.

Reimagine your Membranes

ZwitterCo membrane-based solutions can help you meet discharge goals or unlock onsite water reuse, all with a small footprint and no biological treatment required.

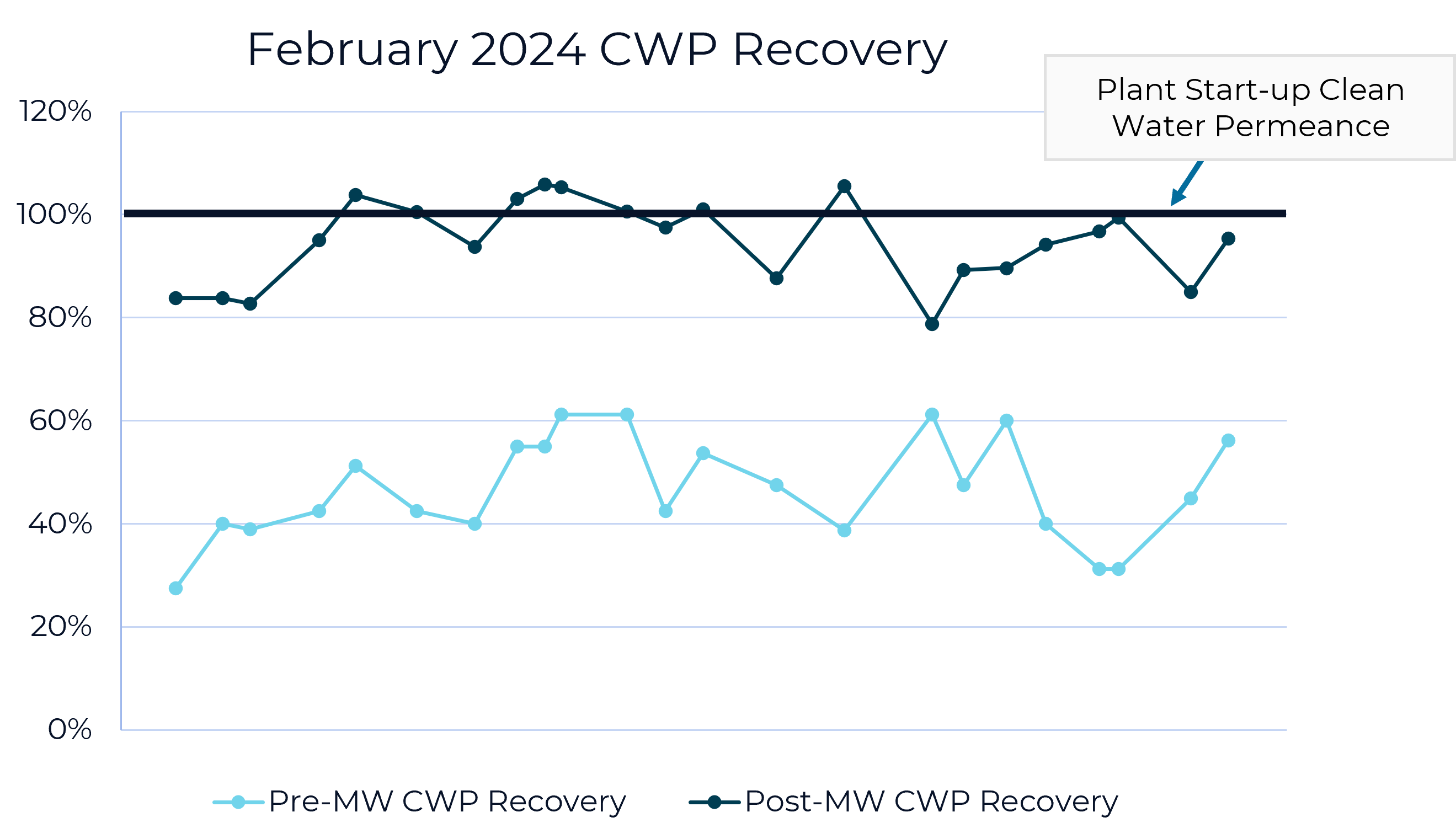

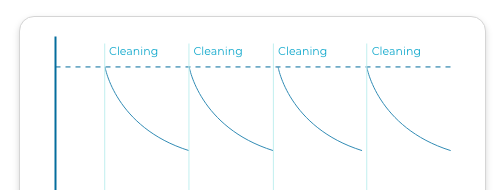

Membrane still performing like new in commercial operation

- Clean water permeance (CWP) data after >16 months of operation

- Chart shows CWP after cleaning compared to initial performance at start-up

- Full performance recovery after a mild maintenance wash (MW) - water flush and caustic with chlorine if needed.

Ready to conduct a feasibility study?

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

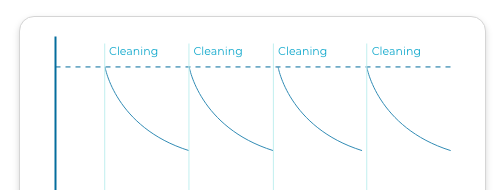

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

No wear and tear

Reliable treatment quality

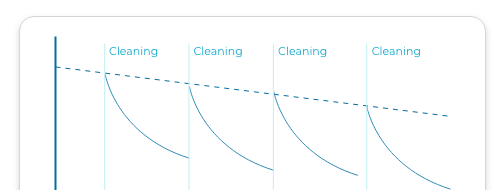

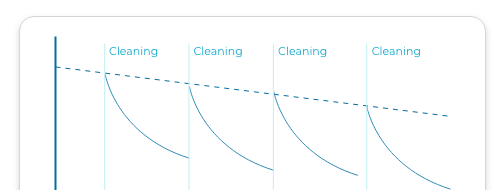

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

Short lifespans from degradation

Compromised performance

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

ZWITTERIONIC MEMBRANES

Description of our cleaning difference from regular membranes.

- Full restoration

- No wear and tear

- Reliable treatment quality

REGULAR MEMBRANES

Description of our cleaning difference from regular membranes.

- Incremental loss

- Short lifespans from degradation

- Compromised performance