Your Process is Possible with Evolution Membranes.

These novel anti-fouling membranes enable affordable and predictable operations for bioprocessing separations that were not possible with conventional membranes. With their stable performance and cleanability, Evolution membranes allow bioprocessors to achieve high-yield separations despite the presence of foulants.

Zwitterionic Technology Unlocks Anti-Fouling Membranes for Bioprocessing.

Evolution membranes feature a patented zwitterionic chemistry which serves as a permanent barrier to irreversible organic fouling, making them ideal for downstream processing or many other streams within bioprocessing. This proprietary anti-fouling chemistry is extremely hydrophilic while actively displacing or repelling organic compounds so they cannot adhere to and foul the membrane.

These membranes offer the highest resistance to organic fouling with stable membrane flux, enabling users to benefit from simpler cleaning programs and reliable operations. Bioprocessors can achieve higher product concentrations and increase achievable purity, while supporting sustainability targets.

Evolve your process with ZwitterCo membranes.

Watch to discover the impact of Evolution SF membrane technology at Solugen.

2x+ improvement in cleaning times

400% savings in membrane costs within 9 months

Full flux recovery with just a warm rinse and caustic wash

What Challenges Can ZwitterCo Solve for You?

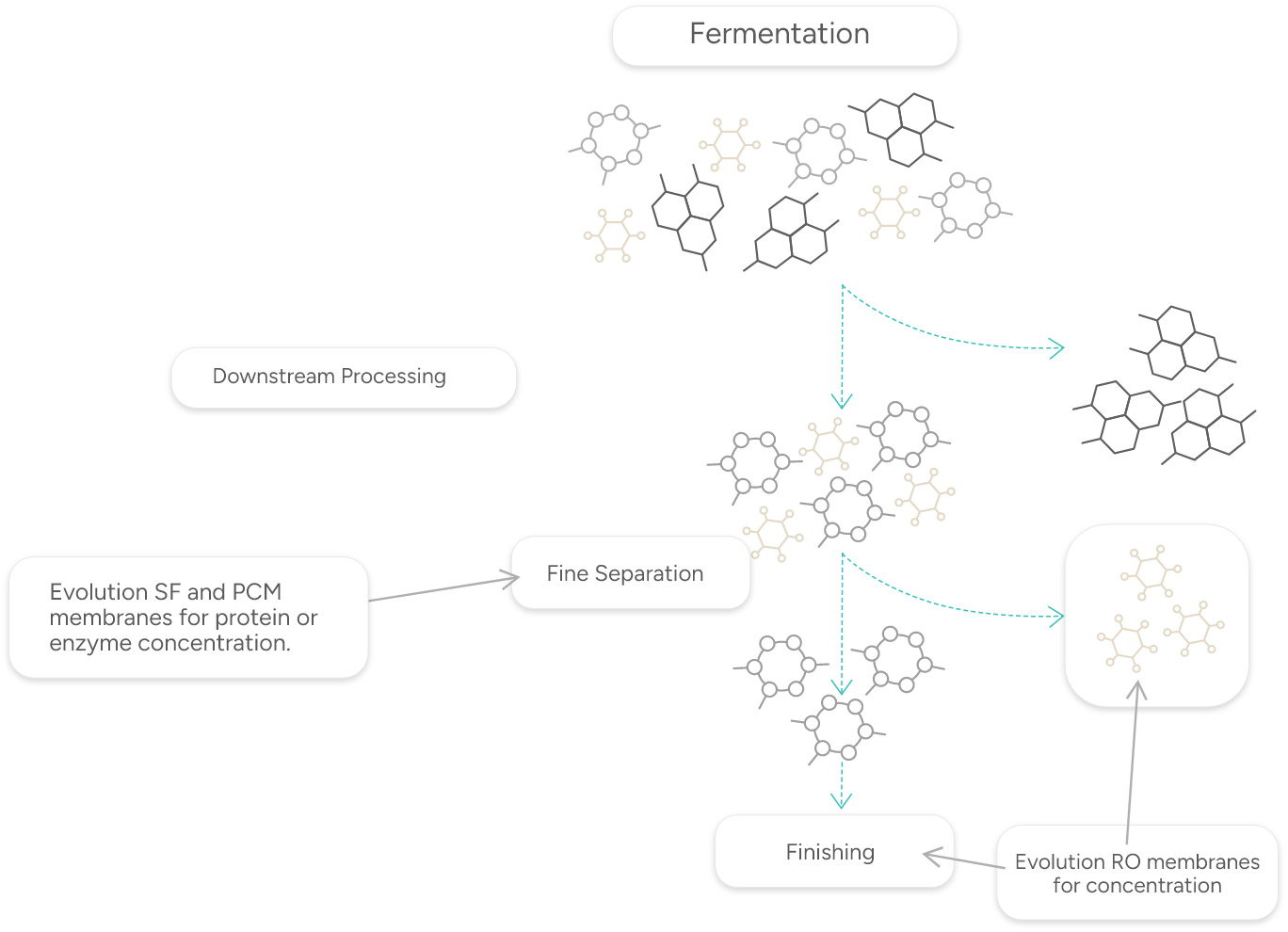

Downstream Processing

Evolution membranes are available in sanitary designs for food-grade applications and offer unprecedented anti-fouling properties, intrinsic pore uniformity, and fast and easy permeance recovery. This results in higher product yield, increased throughput, longer uptime, and lower cleaning program costs.

Industrial Bioprocessing

ZwitterCo also offers non-sanitary membrane options to tackle organics in bioprocessing applications that are not considered food-grade. Achieve longer production runs, more stable flux, and lower operating costs with membranes that provide the highest resistance to organic fouling.

Downstream processing

Easier and less frequent cleanings.

Experience the simplest membrane cleaning program possible for bioprocessors while achieving full permeance recovery, thanks to Evolution membranes’ high resistance to organic fouling. By cleaning less frequently while recovering performance, users are able to achieve longer production runs, higher product yield, and lower operating expenses.

Increase plant efficiency.

Evolution membranes operate at a more stable flux than conventional membranes, resulting in a higher average flux, allowing users to benefit from greater productivity and throughput and longer runs before cleaning. This allows for producing more from existing equipment with stable and predictable performance, increasing overall plant efficiency.

“Our process would not be profitable or possible without ZwitterCo membranes.”

– Dr. Konrad Miller, VP, Manufacturing, Science, & Technology, Solugen

Multiple Options in Downstream Processing

From proteins, amino acids, enzymes, and final products, Evolution membranes can help in a variety of ways.

Permeance recovery and intrinsic pore uniformity.

Evolution membranes offer intrinsic pore uniformity and permeance recovery, which results in:

- Higher product yield

- Increased throughput

- Longer uptime

- Lower cleaning costs

Easy integration.

Evolution membrane elements are designed to be one-for-one substitutes for conventional full-fit membranes and are available in sanitary designs for food-grade bioprocessing applications, allowing users to use their existing membrane equipment or acquire industry-standard membrane equipment.

This seamless integration not only simplifies the upgrade process but also paves the way for future plant expansions and system scalability.

industrial bioprocessing

Achieve longer production runs and stable flux.

Evolution membranes offer the highest resistance to organic fouling with stable membrane flux, resulting in less frequent cleanings.

Bioprocessors experience these benefits with more predictable and stable operations that allow them to make more product with the same equipment or to make product with a process that was not possible with conventional membranes.

Decrease cleanings, increase membrane lifetime.

Membrane fouling leads to increased cleaning frequency and intensity and irreversible fouling, which all contribute to decreased membrane lifespan.

With an anti-fouling technology that decreases cleaning frequency and duration while preventing irreversible fouling, Evolution membranes can last much longer in tough applications that conventional membranes cannot practically handle.

Lower OPEX.

Evolution membranes are extremely anti-fouling, allowing for longer membrane life, less-frequent membrane replacements, and simpler and faster cleaning programs—lowering overall operating expenditure.

Reducing water and energy use while decreasing waste also lead to sustainability gains, allowing bioprocessors to develop more cost-effective and sustainable processes.

Transform waste from cost to benefit.

With their ability to handle foulants, ZwitterCo membranes enable co-product capture in a variety of streams. By using these anti-fouling membranes, bioprocessors are able to capture lost product during the wastewater treatment process to ultimately increase yields and reduce waste.

ZwitterCo offers novel wastewater solutions that can handle the foulants present in bioprocessing wastewaters.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.