A Year of Momentum: ZwitterCo’s 2025 Recap

December 17, 2025News & Announcements,Blogs

As 2025 comes to a close, we’re taking a moment to reflect on a year defined by execution, scale, and proof. Across our Evolution, Elevation, and Expedition product families, one theme stands out clearly: zwitterionic membrane technology is no…

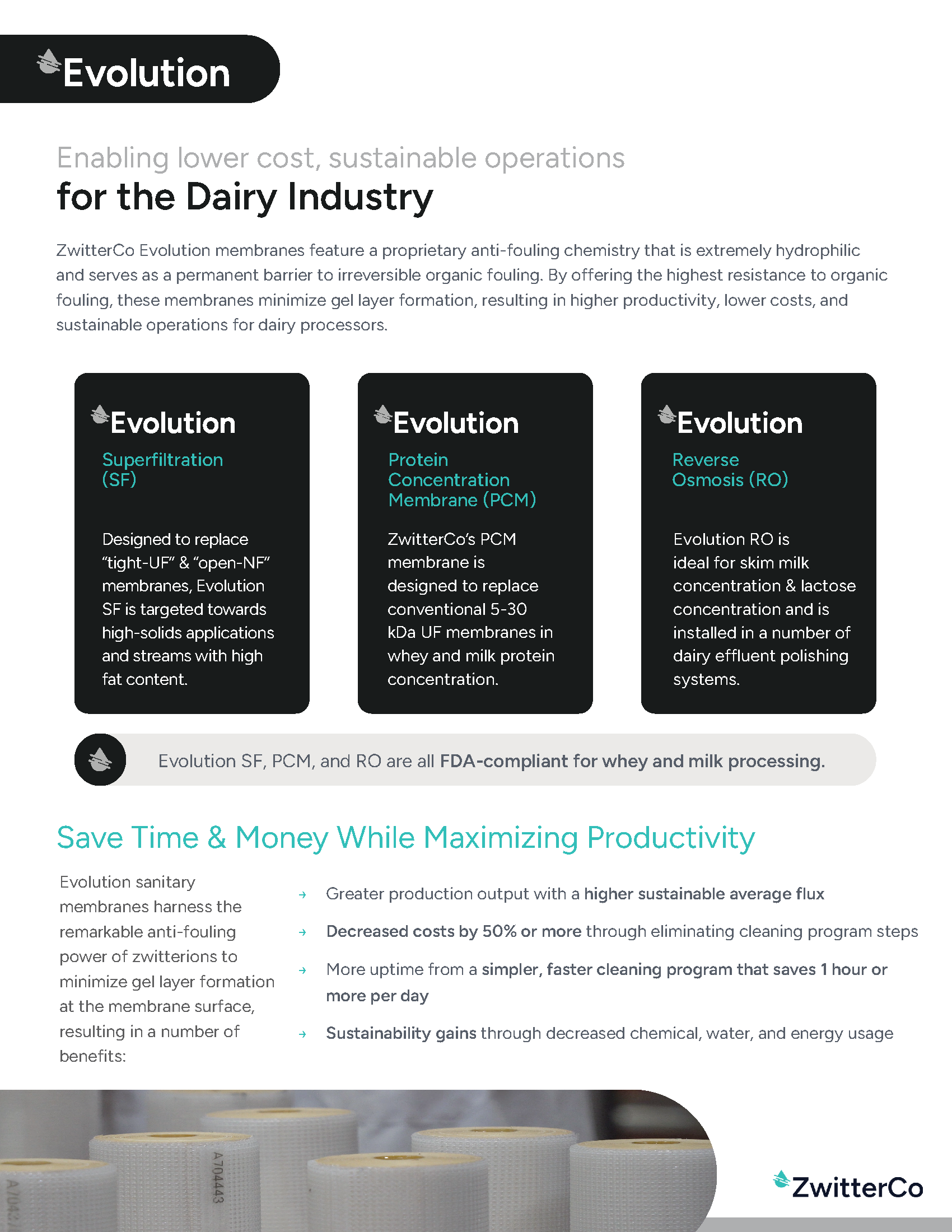

A New Standard for UF Milk Concentration

December 15, 2025Blogs,Evolution

Operating flux during milk concentration is primarily shaped by the gel layer – the dynamic barrier that naturally forms on the membrane surface as product is concentrated. This gel layer develops because protein, fat, and other retained solids…

How ZwitterCo Is Enabling Climate-Resilient Water Reuse Across Industry

December 9, 2025Blogs,Industrial Wastewater,Elevation,Expedition

Climate-driven water scarcity is reshaping how industrial facilities operate. Drought, tightening discharge limits, and rising freshwater costs are forcing manufacturers, processors, and energy producers to rethink how they manage and reuse water.…

A More Productive Path to WPC35: Faster Cleaning, Higher Flux

November 24, 2025Blogs,Evolution

Why Evolution Protein Concentration Membrane (PCM) Is Raising the Productivity Bar in WPC35 WPC35 concentration is typically designed for reliability and consistency, with operating conditions that allow conventional UF membranes to run smoothly…

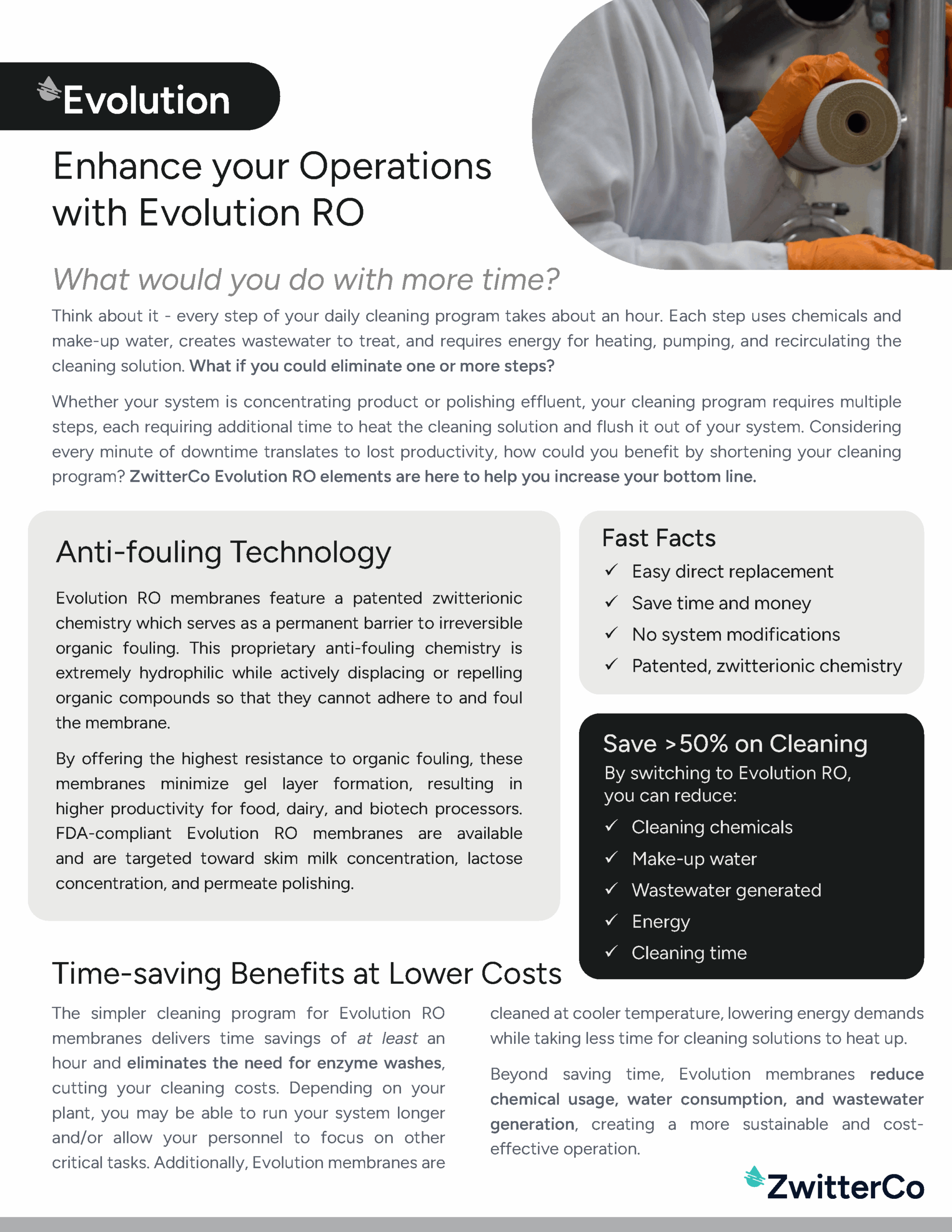

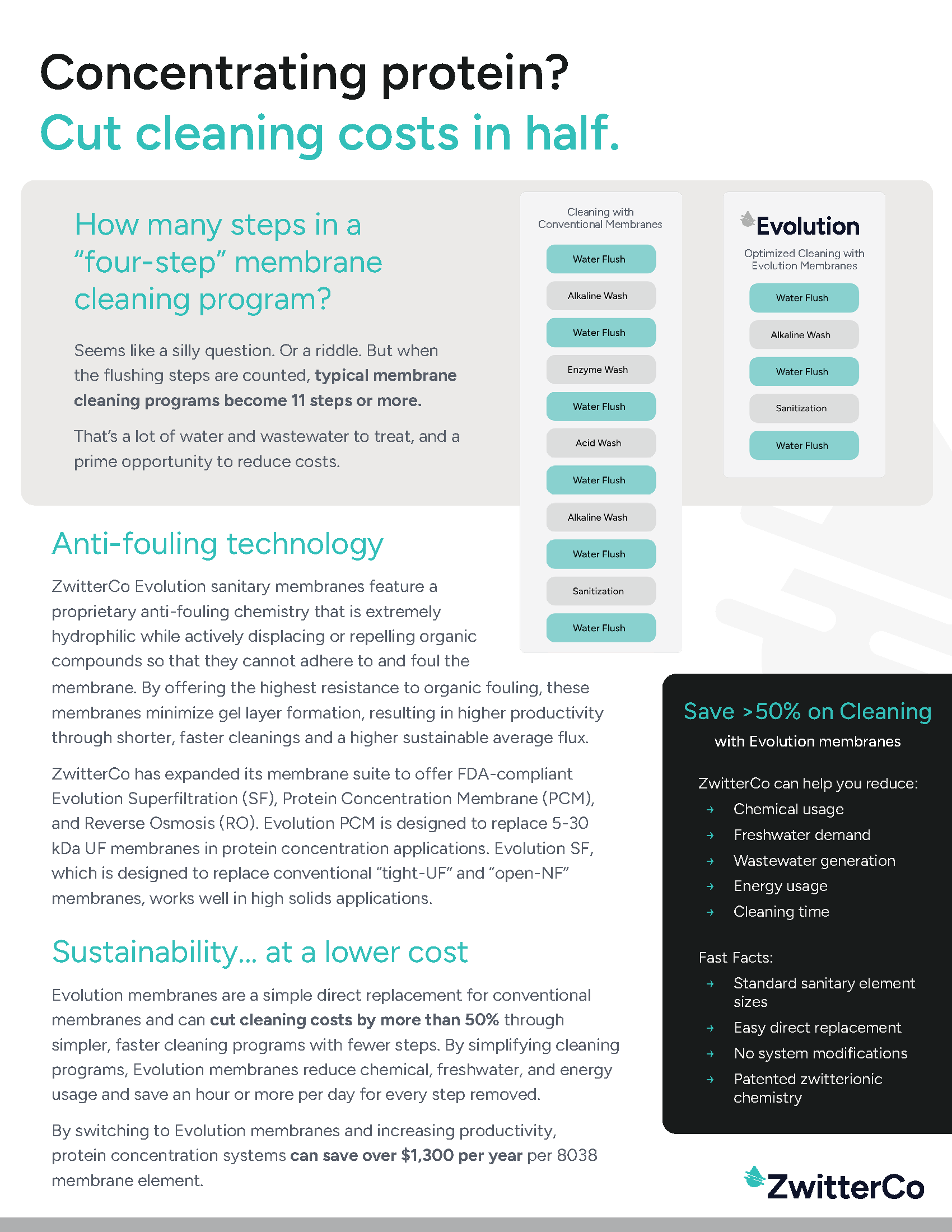

Cutting the Enzyme Cleaning Step with Anti-fouling Membranes

November 17, 2025Blogs,Evolution

Every cleaning step in a membrane system takes time, water, chemicals, and energy. For many processors, enzyme washes are the most expensive of all. ZwitterCo Evolution membranes can remove one or more cleaning steps – including the enzyme step – to…

Closing the Loop on Process Water

November 10, 2025Blogs,Evolution

Across the food and beverage industry, water reuse has shifted from a sustainability aspiration to an operational requirement. Rising discharge costs, tightening regulations, and the ongoing pressure to reduce water intensity have made reuse a…

ZwitterCo Achieves FDA Compliance for Evolution RO and PCM Membranes, Expanding Capabilities for Whey and Milk Processing

November 5, 2025News & Announcements,Blogs,Evolution

Woburn, MA – Nov, 5, 2025 | ZwitterCo, a global leader in membrane solutions for challenging liquid separations, today announced that its Evolution Reverse Osmosis (RO) and Protein Concentration Membrane (PCM) products are now FDA-compliant for whey…

PFAS Pressure: Navigating PFAS Management within Leachate Treatment

October 27, 2025Blogs,Landfill Leachate,PFAs

The regulatory landscape for PFAS (per- and polyfluoroalkyl substances) is shifting fast – especially for landfill leachate. The U.S. EPA’s Plan 15 signals that revised Effluent Limitations Guidelines (ELGs) for landfill leachate are warranted and…

Making Downstream Processing More Economically Feasible

October 20, 2025Blogs,Food, Dairy, & Bioprocessing,Evolution

Downstream processing (DSP) in fermentation and enzyme operations involve separations that are ideal for membranes. Unfortunately, conventional membranes in DSP often fight a losing battle against fouling. Every time flux drops, cleaning length and…

Improving WPC80 and WPI90 Operating Efficiency with Evolution SF

October 13, 2025Blogs,Evolution,Dairy Processing

Achieving high protein concentrations in WPC80 and WPI90 processing has traditionally required a tradeoff between solids and flux. Proteins and other organics tend to adhere to conventional polyethersulfone membranes, so as solids increase, the…

Evolution Anti-Fouling Membranes: Applications & Regulatory Status

October 6, 2025Blogs,Evolution

Q: Is there a white paper that outlines the data shown regarding “cost savings of 50%” and “using 40% less water?” A: Yes, there is a case study on our website showing this data from a US-based whey processor using Evolution RO to concentrate…

Evolution Anti-Fouling Membranes: Technology and Product Details

September 29, 2025Blogs,Evolution

Q: What are the operating pressure limits for Evolution membranes? A: Evolution membranes are designed to be direct replacements for conventional sanitary membranes and are designed to have the same pressure limits. Pressure is mainly a function of…

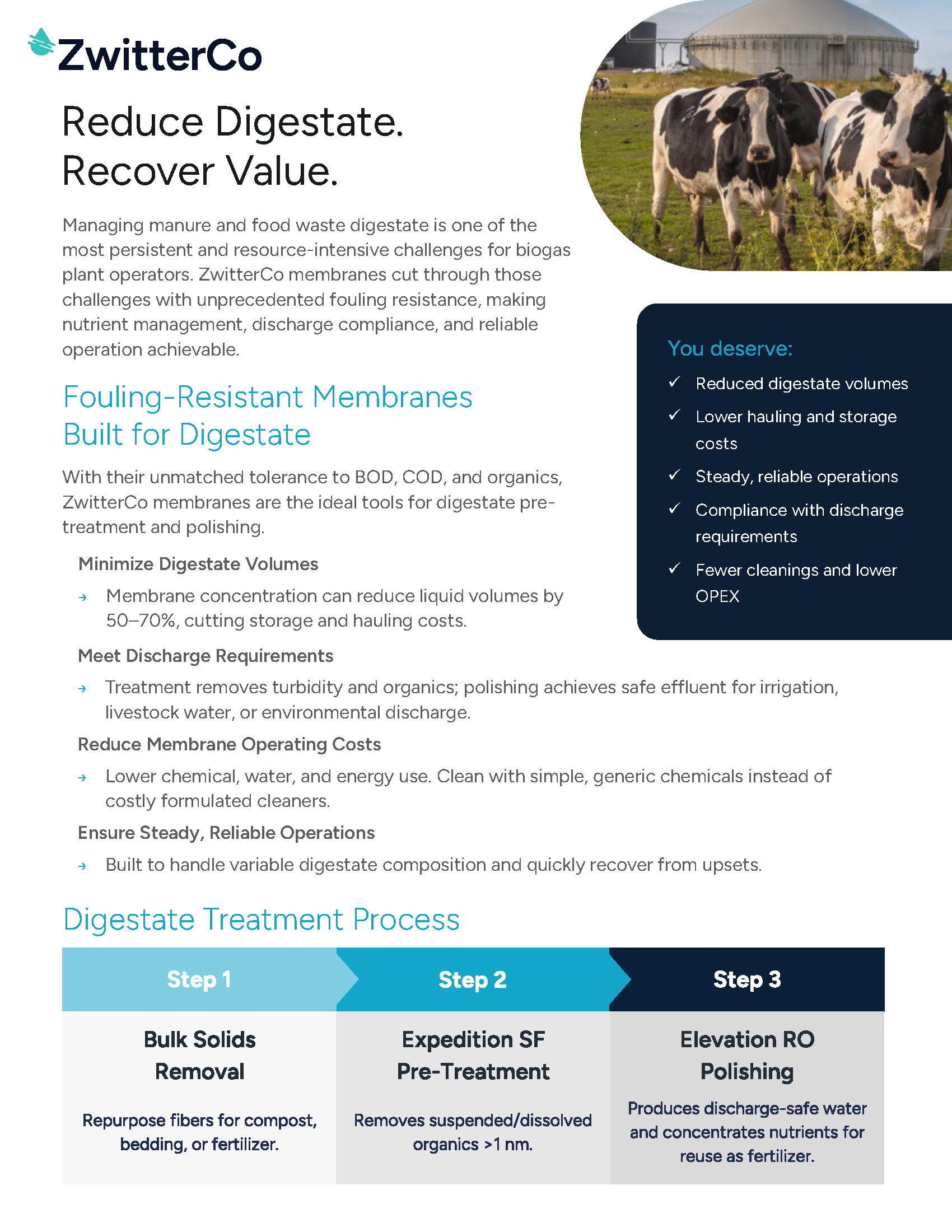

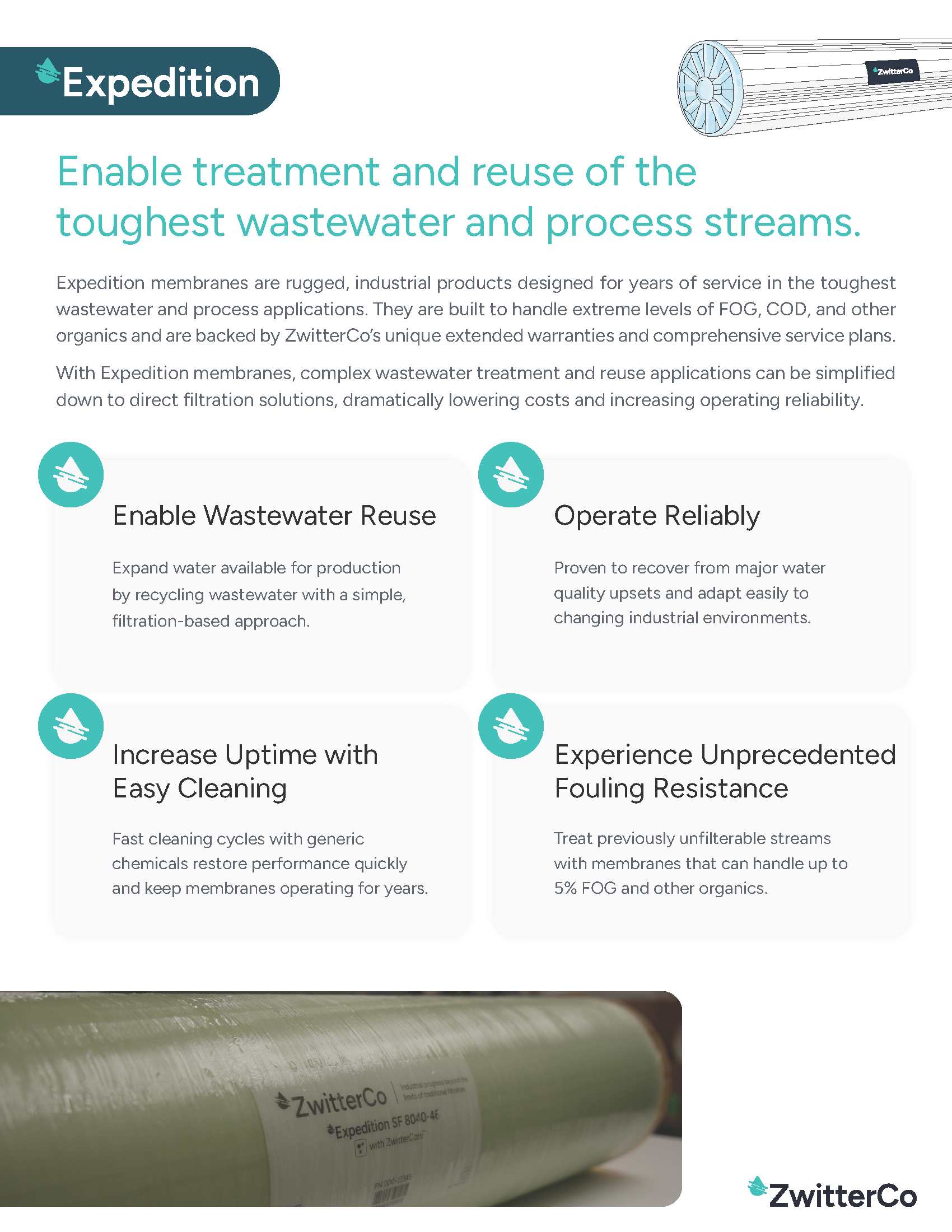

Opening New Frontiers in Industrial Wastewater Treatment: Meet ZwitterCo Expedition

September 22, 2025Blogs,Expedition

For industrial facilities managing high-strength or complex wastewater, traditional membrane technologies have often proven inadequate - especially when oil & grease, COD, turbidity, or elevated suspended solids are present. ZwitterCo Expedition…

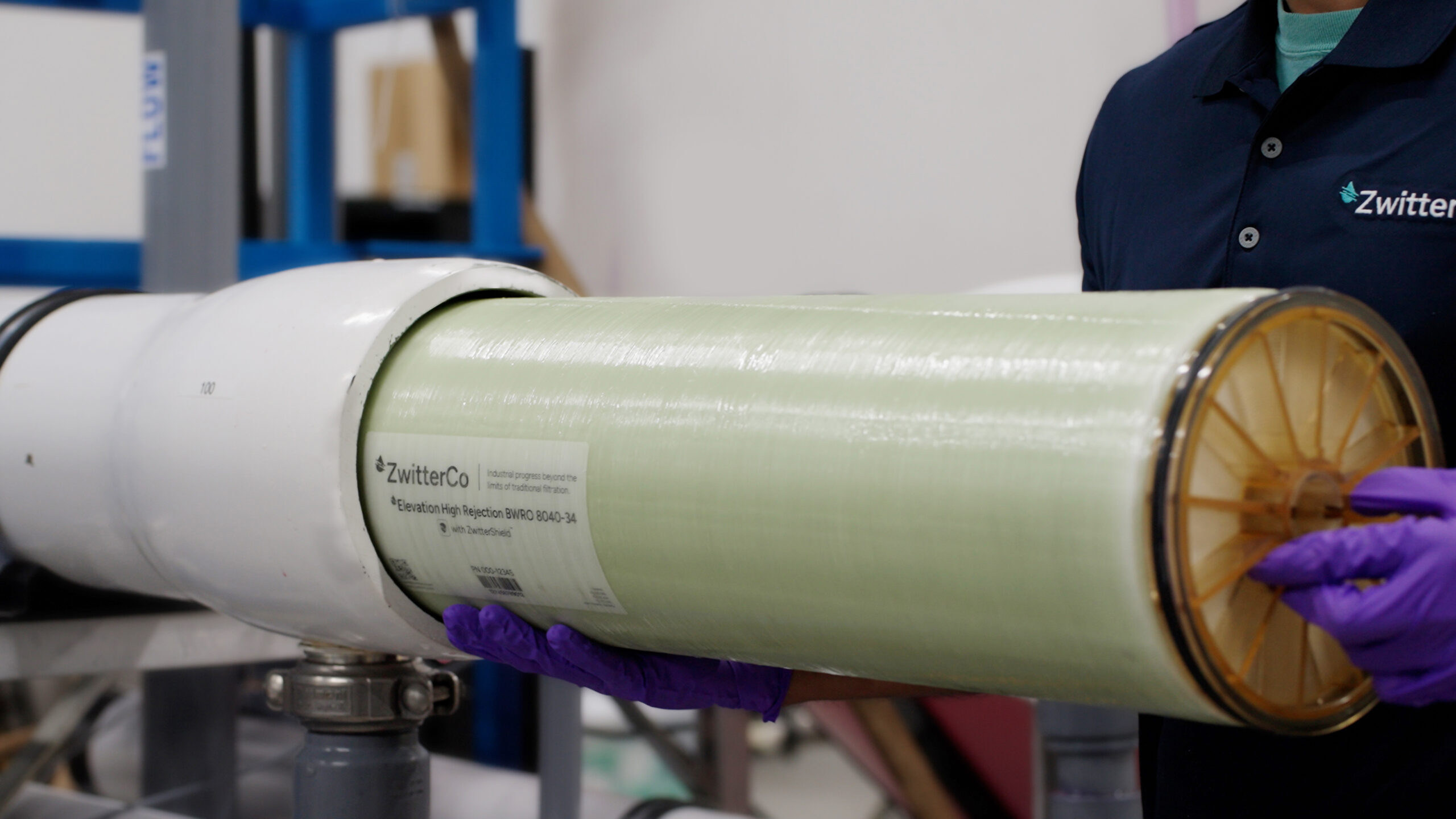

ZwitterCo Elevation: Membranes with the Industry’s Highest Resistance to Organic Fouling

September 15, 2025Blogs,Elevation

Organic fouling is one of the most pressing issues faced by industries using reverse osmosis (RO) membranes, leading to increased maintenance, higher chemical usage, and costly downtime. ZwitterCo’s recently announced Elevation product family…

Anti-Fouling Membranes: The Next Evolution in Dairy & Food Processing

September 8, 2025Blogs,Evolution

Dairy and food processors face continuous pressure to improve operational efficiency, reduce costs, and meet ambitious sustainability targets. ZwitterCo’s Evolution sanitary membranes provide the breakthrough solution processors have been waiting…

ZwitterCo Launches Evolution Membranes, Transforming Dairy and Food Processing Efficiency

September 4, 2025News & Announcements,Blogs,Evolution

Woburn, MA – Sept. 4, 2025. | ZwitterCo, a global leader in membrane solutions for challenging liquid separations, has announced the commercial release of its Evolution membrane product family. These next-generation membranes are engineered to help…

Zwitterions in Antifouling Surfaces

September 1, 2025Blogs,Zwitterions

Zwitterions are gaining attention across industries for their remarkable ability to resist fouling, enhance biocompatibility, and maintain clean, functional surfaces in challenging environments. While ZwitterCo has pioneered the use of zwitterionic…

Zwitterions in Drug Delivery

August 25, 2025Blogs,Zwitterions

Zwitterions are gaining attention across industries for their remarkable ability to resist fouling, enhance biocompatibility, and maintain clean, functional surfaces in challenging environments. While ZwitterCo has pioneered the use of zwitterionic…

Zwitterions in Medical Devices

August 18, 2025Blogs,Zwitterions

Zwitterions are gaining attention across industries for their remarkable ability to resist fouling, enhance biocompatibility, and maintain clean, functional surfaces in challenging environments. While ZwitterCo has pioneered the use of zwitterionic…

5 Brewery & Distillery Wastewater Mistakes That Are Costing You Money

August 11, 2025Blogs,Food & Beverage,Brewery & Distillery

Crafting quality beverages is your passion but ignoring your wastewater could be draining your profits. For breweries and distilleries, wastewater is a byproduct that’s often underestimated in cost and complexity.

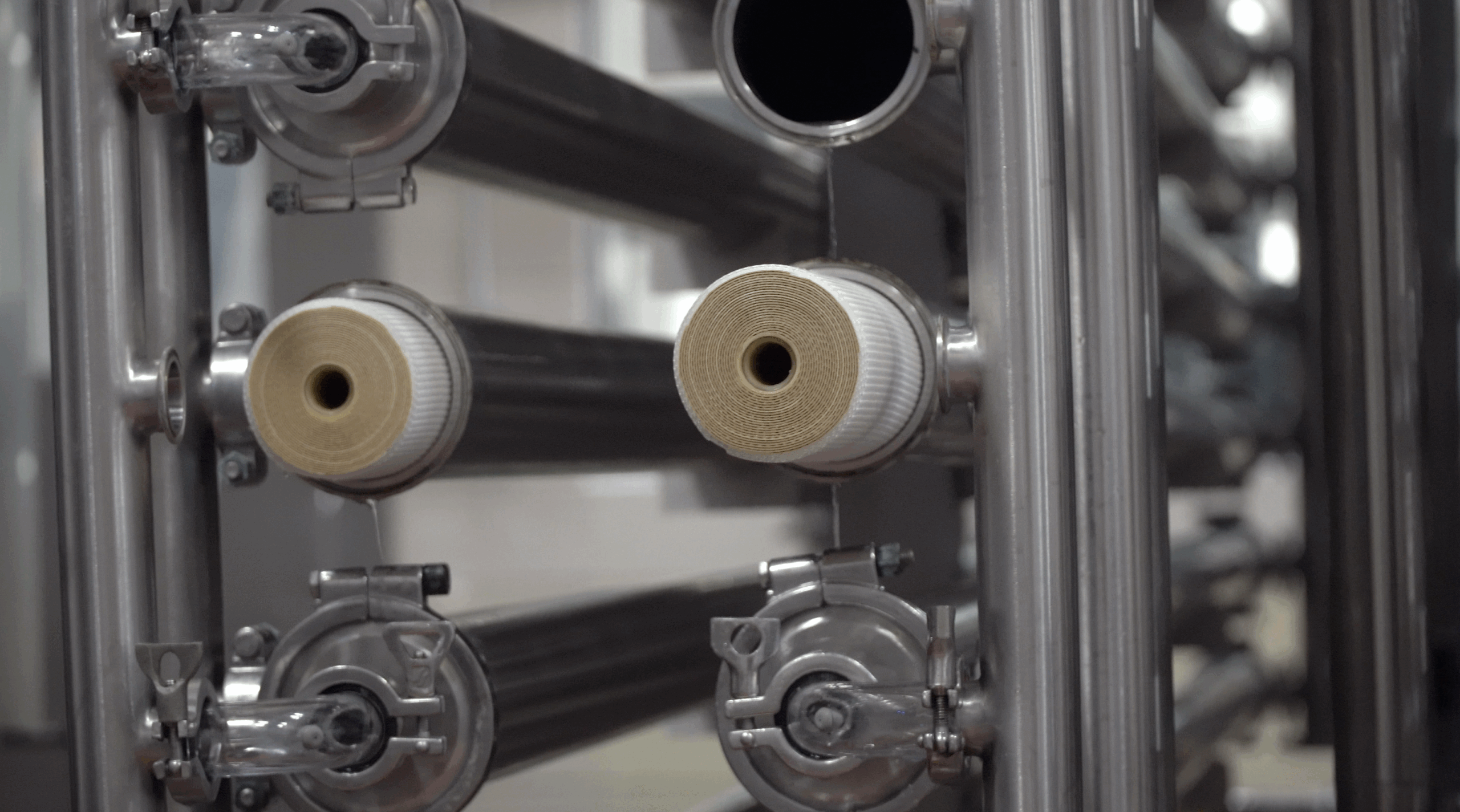

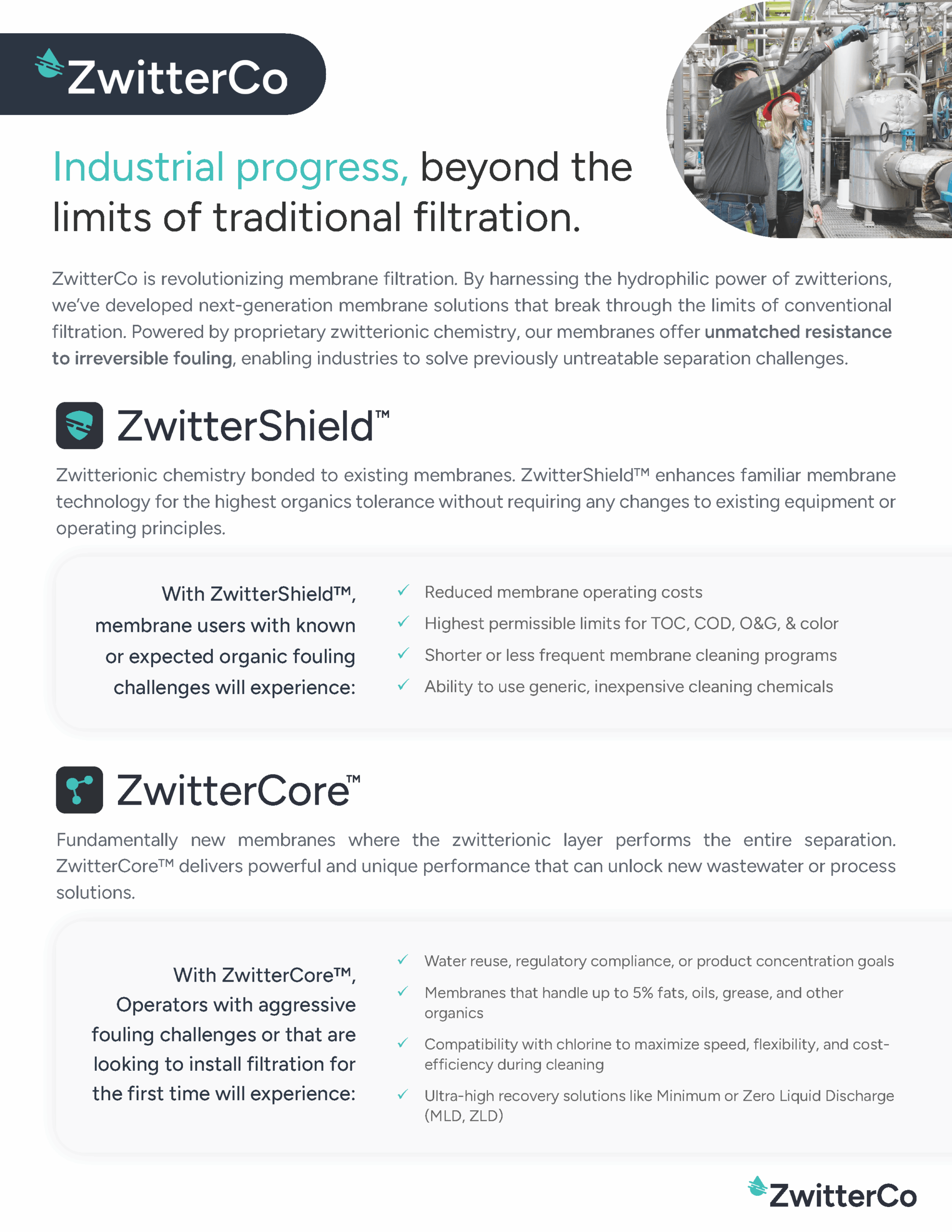

ZwitterShield™ and ZwitterCore™: Redefining Industrial Membrane Performance

Addressing the Limitations of Conventional Membranes Industrial membranes have been indispensable for applications such as water purification, wastewater management, and the precise separation of high-value substances across sectors including food…

Turning MBR Effluent into Reliable Cooling Water with ZwitterCo Elevation RO

July 29, 2025Customer Success Stories,Food & Beverage,MBR + RO

An industrial facility using MBR-treated wastewater for cooling tower makeup water faced recurring issues with its RO system. The upstream ultrafiltration unit was underperforming, allowing organics to reach the RO membranes and resulting in…

ZwitterCo Expands Portfolio of the Industry’s Most Fouling-Resistant Membranes with Elevation, Evolution, and Expedition

July 24, 2025News & Announcements,Blogs,Elevation,Evolution,Expedition

Introducing a new era of sustainable membranes for food processing and industrial water reuse & wastewater treatment Woburn, MA – July 23, 2025. ZwitterCo, a global leader in advanced membranes for challenging separations, has unveiled three…

Demonstrating Cost Effective Cleaning and Stable Membrane Performance with AST Advanced RO Membrane System Leveraging ZwitterCo Elevation RO for Landfill Leachate Treatment

July 10, 2025Case Studies,Industrial Wastewater,Landfill Leachate

Download Case Study Demonstrating Cost Effective Cleaning and Stable Membrane Performance with AST Advanced RO Membrane System Leveraging ZwitterCo Elevation RO for Landfill Leachate Treatment AST is a Portugal-based environmental technology company…

Industrial Water Resiliency in the Middle East: Insights from ZwitterCo's Fireside Chat

June 18, 2025Webinars & Events,Blogs,Industrial WastewaterWebinar

Water scarcity is an escalating concern in the Middle East, compelling industries to seek innovative solutions for water reuse and sustainability. In a recent fireside chat, ZwitterCo's leadership team, CEO Alex Rappaport, Chief Commercial Officer…

The Versatile Power of Zwitterions: Beyond Water Treatment

At ZwitterCo, zwitterions are more than a namesake. They are the foundation of our membrane technology and an innovation in material chemistry with far-reaching potential across industries. These uniquely structured molecules carry both a positive…

Reduce Your Chemical Footprint: Smarter DAF Operations for Meat & Poultry Plants

May 21, 2025Blogs,Food & Beverage,Meat & Poultry

Dissolved Air Flotation (DAF) systems are essential tools in the meat and poultry industry, tasked with removing fats, oils, grease (FOG), and total suspended solids (TSS) from wastewater. However, their heavy reliance on chemical additives can…

Fouling resistant ZwitterCo Elevation RO Membrane Deployment for High-Strength Biorefinery Wastewater Treatment

May 20, 2025Case Studies,Elevation

Download Case Study Case Study: Fouling resistant ZwitterCo Elevation RO Membrane Deployment for High-Strength Biorefinery Wastewater Treatment In pursuit of a more robust solution for complex sugar refinery wastewater, a biorefinery partnered with…

Turning the Tide: How Advanced Membrane Technology Can Help Meat & Poultry Processors Meet Evolving EPA Standards

May 13, 2025Blogs,Food & Beverage,Meat & Poultry

The meat and poultry processing industry faces increasing pressure to manage wastewater discharges effectively. Recent high-profile enforcement actions and penalties underscore growing scrutiny by the U.S. Environmental Protection Agency (EPA). With…

Enhancing Wastewater Treatment Capacity in Poultry Processing with ZwitterCo Superfiltration (SF)

May 8, 2025Blogs,Food & Beverage,Food, Dairy, & Bioprocessing,Superfiltration,Food ProcessingMeat & Poultry

A poultry processor planning a major production expansion encountered a significant limitation: the existing wastewater treatment system lacked the capacity to meet future discharge requirements. Installing additional chemically-assisted DAF units…

6 Smart Ways Dairy Processors Can Simplify Membrane Cleaning Programs and Maximize Production Time

May 2, 2025Blogs,Food, Dairy, & Bioprocessing,Dairy Processing

For dairy processors, cleaning programs are a critical yet resource-intensive routine directly impacting productivity, operating costs, and sustainability goals. Conventional cleaning programs, while effective, rely heavily on chemicals, significant…

Lower Cost Cleanings & Better Leachate Treatment with ZwitterCo Membranes

April 24, 2025Customer Success Stories

A landfill in southwestern Europe was facing persistent operational and financial stress while managing high-strength leachate. The facility’s first-pass RO system required frequent cleanings with costly formulated chemicals, driving up costs and…

Reducing Cleaning Costs and Downtime in Leachate Treatment with ZwitterCo’s Fouling-Resistant RO

April 17, 2025Customer Success Stories

A landfill in Europe faced constant disruptions in its leachate treatment process due to severe organic fouling. These issues led to excessive chemical cleaning, frequent membrane replacements every two months, and prolonged downtime, driving up…

ZwitterCo™ Introduces New FDA Compliant Anti-Fouling Membranes for Whey Processing

April 14, 2025News & Announcements,Blogs,Evolution

Originally posted by FoodBev Media WOBURN, Mass., | April 14, 2025 – ZwitterCo is proud to announce the availability of a new product line of sanitary superfiltration (SF) spiral membrane elements featuring its second-generation SF technology.…

5 Leachate Treatment Mistakes Costing Your Landfill Money

April 14, 2025Blogs,Industrial Wastewater,Landfill Leachate

Landfill leachate treatment is a necessary but expensive part of waste management. Many landfill operators unknowingly make decisions that increase operating costs, shorten equipment life, and limit the potential for water reuse. Avoiding these…

Optimizing Refinery Wastewater Treatment with Advanced RO Membranes

April 10, 2025Customer Success Stories

A refinery in Europe faced persistent challenges in treating wastewater with high total organic carbon (TOC) and low levels of oil and grease. Conventional RO membranes struggled to maintain performance, requiring frequent cleanings and limiting…

The Price of Performance: Understanding Dairy Membrane Costs

April 6, 2025Blogs,Food, Dairy, & Bioprocessing,Evolution,Dairy Processing,Dairy Wastewater

Membrane technology has become indispensable in the dairy industry, enabling processes from milk concentration to whey fractionation. Despite their many advantages, membrane systems come with a variety of operational costs: high specialty chemical…

Revolutionizing Grain Processing: A Sustainable Success Story

April 4, 2025Customer Success Stories,Ethanol

A grain processing facility was facing significant challenges managing a complex wastewater stream filled with variable organics, inorganics, and salts. Their existing evaporators were unable to handle additional loads without affecting the plant’s…

Biotech Efficiency Reimagined: Unlocking 400% in Savings

March 27, 2025Customer Success Stories

Biotech Efficiency Reimagined: Unlocking 400% in Savings A sustainable chemical plant in Texas was facing frequent membrane fouling that disrupted operations, increased downtime, and drove up costs. Their water-based production process, which relies…

Demonstrating Reliable Performance and Cleaning Cost Reduction with ZwitterCo Elevation RO Membranes for Landfill Leachate

March 26, 2025Case Studies,Elevation,Landfill Leachate

Download case study Case Study: Demonstrating Reliable Performance and Cleaning Cost Reduction with ZwitterCo Elevation RO Membranes for Landfill Leachate Serpol is a leading environmental services company in France with over four decades of…

Why Refineries Are Turning to Advanced Membrane Filtration

March 24, 2025Blogs,Industrial Wastewater,Refineries

Water management is crucial for oil refineries, used in everything from initial crude processing to cooling towers and the steam and power generation required to run complex equipment. Yet, managing refinery wastewater has grown increasingly…

Revolutionizing Leachate Treatment: A Cost-Saving Success Story

March 20, 2025Customer Success Stories

Revolutionizing Leachate Treatment: A Cost-Saving Success Story A landfill in Europe faced a costly challenge — treating high-strength leachate with conventional RO meant frequent, expensive cleanings that strained operations and budgets. With…

Advancements in Reverse Osmosis Membrane Technology for Tertiary Wastewater Treatment

March 18, 2025Blogs,Industrial WastewaterReverse Osmosis

Across industries, growing environmental regulations and sustainability targets are placing intense pressure on facilities to treat and reuse wastewater. These requirements transcend traditional effluent quality benchmarks and push operations to…

Closing the Loop: Onsite Water Reuse with MBR + Advanced RO in Food & Beverage

March 12, 2025Blogs,Food & Beverage,Reverse OsmosisMBR + RO

In the food and beverage industry, water is essential for everything from ingredient preparation to equipment cleaning. As plants face mounting pressure to conserve and reuse water, simply treating wastewater for discharge may not be enough.…

Leachate Management Challenges Were Driving Up Costs—Until This Landfill Found a Better Way

March 6, 2025Customer Success Stories

Leachate Management Challenges Were Driving Up Costs—Until This Landfill Found a Better Way A U.S. landfill faced persistent challenges with leachate management. Minimal treatment before deep well injection led to severe well fouling and plugging,…

From Fines to Compliance: MBR + Advanced RO Solutions for Food & Beverage Wastewater

March 3, 2025Blogs,Food & Beverage,Reverse OsmosisMBR + RO

The food and beverage industry faces increasingly stringent regulations around wastewater disposal. In particular, plants must meet strict limits on key parameters such as biochemical oxygen demand (BOD), chemical oxygen demand (COD), total…

Tackling Algae and Wastewater Compliance Challenges with ZwitterCo Membranes

February 27, 2025Customer Success Stories

Tackling Algae and Wastewater Compliance Challenges with ZwitterCo Membranes https://zwitterco.com/wp-content/uploads/2025/03/Customer-Success-Video-2.mp4 A major agricultural processing facility in the U.S. was struggling with excessive algal…

Lower Costs, Less Hassle: How Two Dairy Processors Improved Their Wastewater Treatment

February 20, 2025Customer Success Stories,Evolution,Dairy Processing,Dairy Wastewater

Lower Costs, Less Hassle: How Two Dairy Processors Improved Their Wastewater Treatment Two whey processing facilities were operating as usual—regular membrane cleaning cycles, chemical costs adding up, and normal membrane replacements due to wear…

Seasonal Fouling Was Disrupting Operations—Until This Power Plant Made a Change

February 13, 2025Customer Success Stories

Seasonal Fouling Was Disrupting Operations—Until This Power Plant Made a Change https://zwitterco.com/wp-content/uploads/2025/02/Customer-Success-Video-3-4.mp4 A U.S. power plant relied on surface water for boiler make-up, but every spring, rising…

Revolutionizing Landfill Leachate Management: A Success Story

February 6, 2025Customer Success Stories

Revolutionizing Landfill Leachate Management: A Success Story In the Southeastern U.S., a landfill faced unsustainable challenges with leachate management. Rapid fouling of their RO membranes meant weekly replacements, driving up costs, causing…

How Advanced Membrane Solutions Can Transform Landfill Leachate Treatment

February 4, 2025Blogs,Articles,Industrial Wastewater,Landfill Leachate

Originally posted on wasteadvantagemag.com | February 2, 2025 Landfill operators seeking to optimize their leachate treatment processes should consider how advanced membrane solutions could benefit their facilities. With proven success in…

Innovating Leachate Management: A Success Story in Sustainability

January 30, 2025Customer Success Stories

Innovating Leachate Management: A Success Story in Sustainability A landfill in Europe struggled with severe RO membrane fouling, leading to frequent cleanings, higher chemical usage, and extended downtime. These issues made it difficult to maintain…

PFAS, Heavy Metals & Organics: Why RO is the Ultimate Leachate Solution

January 26, 2025Blogs,Industrial Wastewater,Reverse OsmosisLandfill Leachate

The Challenge of Landfill Leachate Treatment Landfill leachate is a complex and highly variable wastewater stream, often containing a mix of heavy metals, organic pollutants, salts, and persistent contaminants like per- and polyfluoroalkyl…

ZwitterCo RO Reduces Cleaning Frequency by Over 70% at US-Based Power Plant

January 17, 2025Case Studies,Industrial Wastewater

Case Study: ZwitterCo RO Reduces Cleaning Frequency by Over 70% at US-Based Power Plant Water is a critical component of power generation – in conventional power plants, water is heated to transform it into steam, which then spins the turbines that…

ZwitterCo™ Recognized on the 2025 Global Cleantech 100 List

January 15, 2025News & Announcements,Awards & Recognition

BOSTON, MA — January 15, 2025 — ZwitterCo, an advanced membrane technology company, has been named on Cleantech Groups 2025 Global Cleantech 100. This annual list, now in its 16th year, showcases the most promising private cleantech companies making…

Unlocking the Full Potential of Water Reuse in Landfill Operations

January 11, 2025Blogs,Industrial Wastewater,Landfill Leachate

Landfills face a dual challenge: managing leachate and meeting sustainability goals. Historically, leachate— the liquid that forms when rainwater flows through waste —has been treated and either disposed of or discharged, often at a significant…

From Directive to Dilemma: Tackling High-Strength Leachate with Advanced Membranes

January 5, 2025Blogs,Industrial Wastewater,Landfill Leachate

The European Union Landfill Directive, implemented to minimize environmental impacts and promote sustainable waste management, has undoubtedly succeeded in reducing the volume of waste sent to landfills. Waste landfilling in the EU has dropped from…

ZwitterCo High Rejection and Low Energy BWRO Membranes Now NSF 61 Certified

November 14, 2024News & Announcements

ZwitterCo’s high rejection and low energy brackish water RO elements have received NSF/ANSI/CAN 61 certification, marking an important milestone in ensuring safe, potable water for municipalities, beverage producers, and other industries. This…

Recap of ZwitterCo at the 2024 International Water Conference®

November 10, 2024Blogs,Tradeshow

The International Water Conference® (IWC) in Las Vegas brought together industry leaders and innovators to tackle pressing water challenges, and ZwitterCo was proud to be a part of it from November 3-7. This year’s conference was packed with…

Unlocking Reuse Potential: RO Membranes in Tertiary Water Treatment for Food and Beverage

October 22, 2024Blogs,Food & BeverageReverse Osmosis

Water is essential across nearly every process in the food and beverage industry, from cleaning and cooling machinery to becoming an actual ingredient in the end products. Given this vast usage, food and beverage facilities face mounting pressure to…

The Hidden Threat of Landfill Leachate: How RO Membranes Offer a Sustainable Solution

October 15, 2024Blogs,Industrial Wastewater,Landfill Leachate

The Growing Threat of Landfill Leachate Landfill leachate is an increasingly concerning byproduct of waste disposal, formed when rainwater seeps through layers of landfill waste, picking up a variety of pollutants along the way – things like heavy…

Achieving Wastewater Compliance in Food & Beverage: How Advanced Membranes Make It Possible

October 8, 2024Blogs,Food & Beverage

In today's food and beverage industry, regulatory compliance around wastewater discharge has never been more crucial. Stricter regulations aim to protect the environment, safeguard public health, and promote sustainable operations. For…

Industrial Water Resiliency in the Era of Water Scarcity

October 6, 2024Resources Page,Webinar,Webinars & EventsWebinar,Elevation,Industrial Water,Resource page

WEBINAR:Industrial Water Resiliency in the Era of Water Scarcity

Solving Food & Beverage Wastewater Challenges in Europe

October 6, 2024Resources Page,Webinar,Webinars & EventsFood & Beverage,Webinar,Food & Beverage Wastewater,Resource page

WEBINAR:Revolutionizing Water & Wastewater Treatment with ZwitterCo Membranes

Elevation Product Introduction Webinar

October 6, 2024Resources Page,Webinar,Webinars & EventsWebinar,Elevation,Elevation,Resource page

WEBINARTransform Water & Wastewater Treatment with Elevation Membranes

Evolution Product Introduction Webinar

October 6, 2024Resources Page,Webinar,Webinars & EventsWebinar,Evolution,Resource page,Evolution

WEBINAREvolution Anti-fouling Membranes: The Next Evolution in Food, Dairy, and Biotech Processing

Expedition SF & Systems One Pager

October 6, 2024BrochureExpedition,Systems & Rentals,Resource page,Brochure

Expedition & Systems One Pager

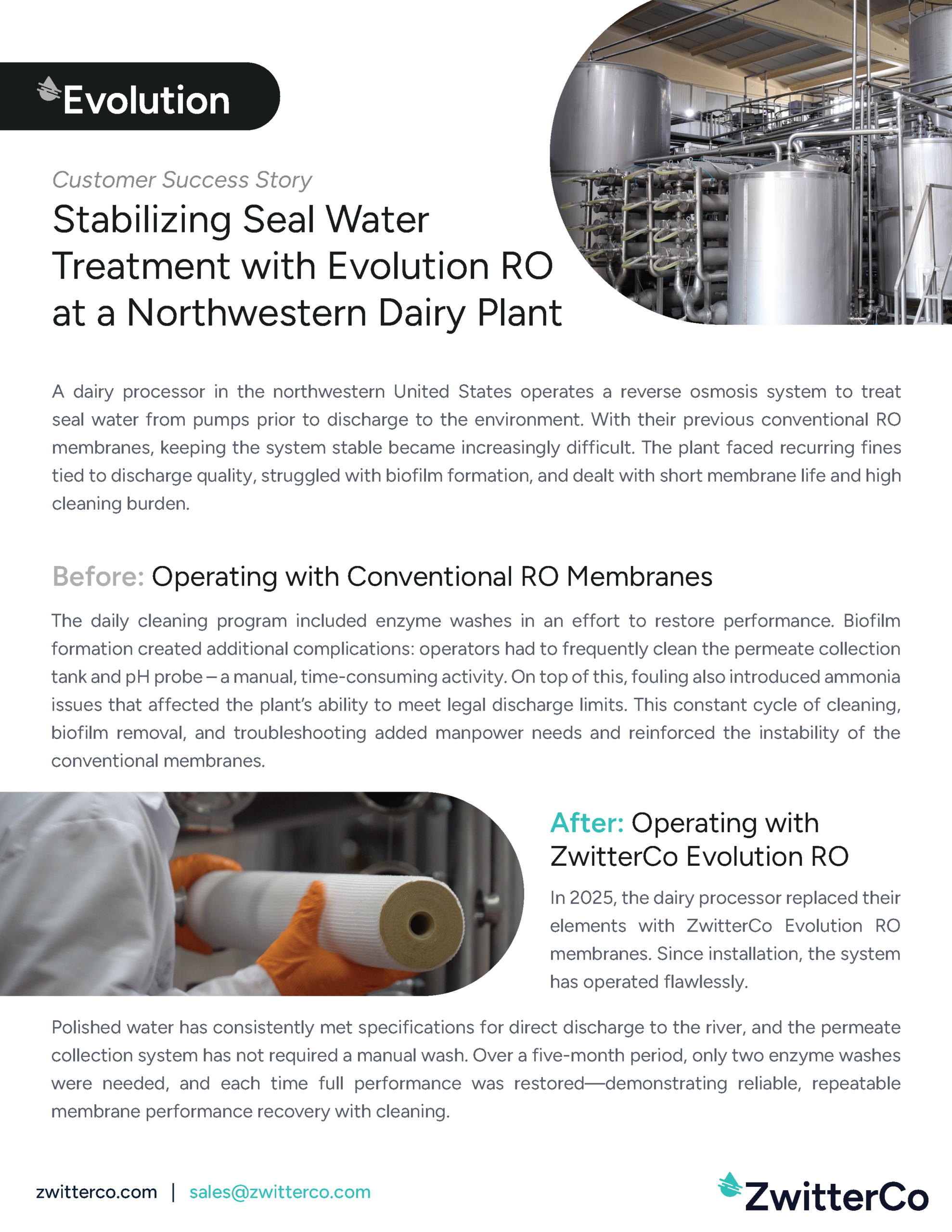

Seal Water Treatment Customer Success

October 6, 2024Case Studies,Evolution,Resource pageCase Study

Seal Water Treatment Customer Success Story

Dairy Flush Water Customer Success

October 6, 2024Case Studies,Evolution,Dairy Processing,Resource pageCase Study

Dairy Flush Water Customer Success Story

PAA Reuse 101: Unlocking Hidden Savings in Meat & Poultry Processing

October 1, 2024Blogs,Food & Beverage,Food, Dairy, & Bioprocessing,Food Processing,Meat & Poultry

In the industry of meat and poultry processing, maintaining food safety standards while optimizing operational efficiency is critical. One essential component of these operations is peracetic acid, or PAA, a highly effective antimicrobial agent.…

Reducing Environmental Impact: How Advanced RO Membranes Improve Landfill Leachate Management

September 25, 2024Blogs,Industrial Wastewater,Landfill Leachate

Landfills are a fact of life, but the environmental impacts they generate can be significant. One of the biggest challenges they pose is landfill leachate—a liquid formed when rainwater filters through waste. This leachate can carry a variety of…

Elevation Brochure Access

September 17, 2024Resources Page,Elevation,BrochureBrochure

BROCHUREZwitterCo Elevation Membranes

RO and the Circular Economy: Reusing Industrial Water to Reduce Overall Consumption

As industries continue to grow, so does the demand for water – one of our most precious resources. In response, the concept of a circular economy has gained traction, aiming to minimize waste and maximize resource efficiency. Water recycling and…

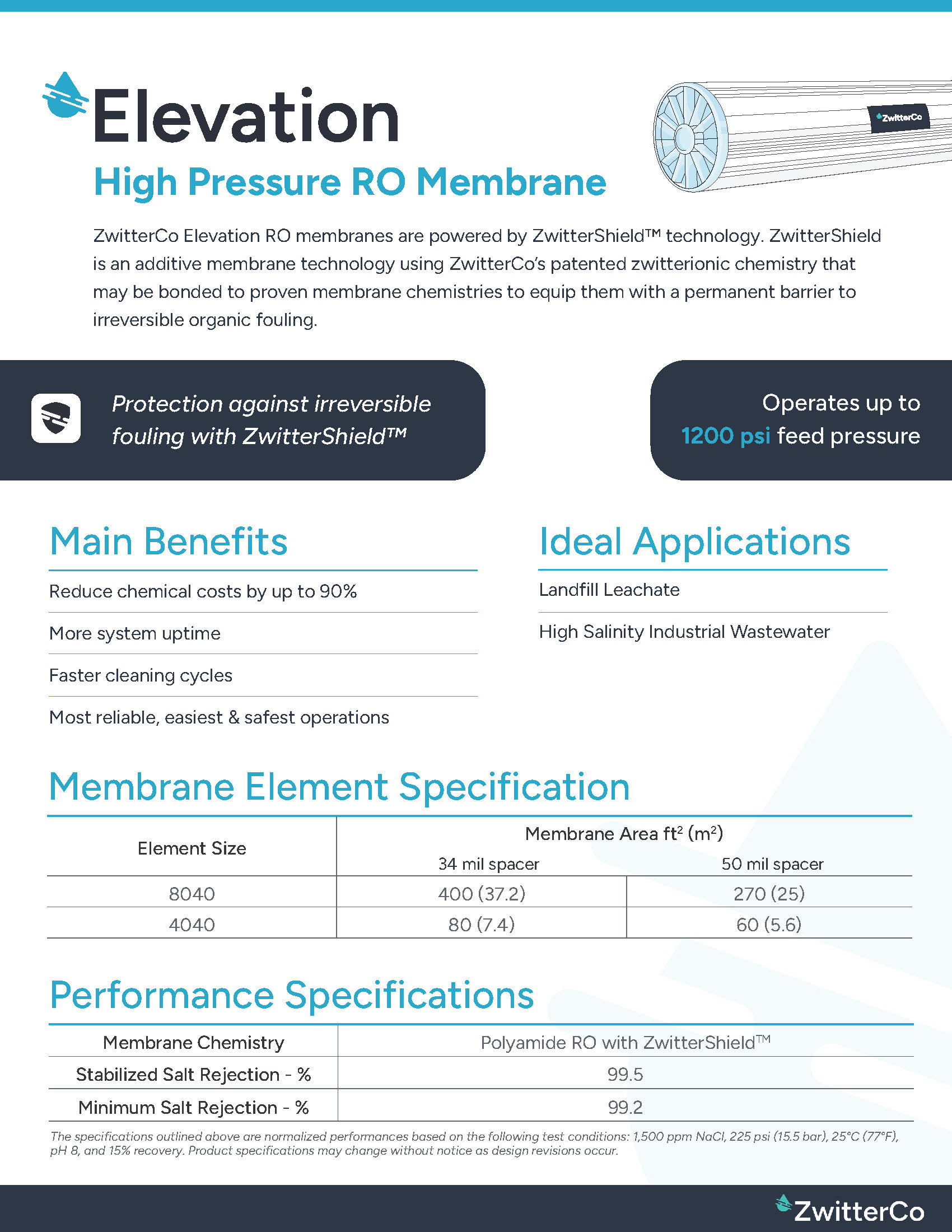

Elevation High Pressure RO Data Sheet

September 15, 2024Resources Page,Elevation,ElevationResource page,Data Sheet,Data Sheet

Elevation High Pressure RO Data Sheet

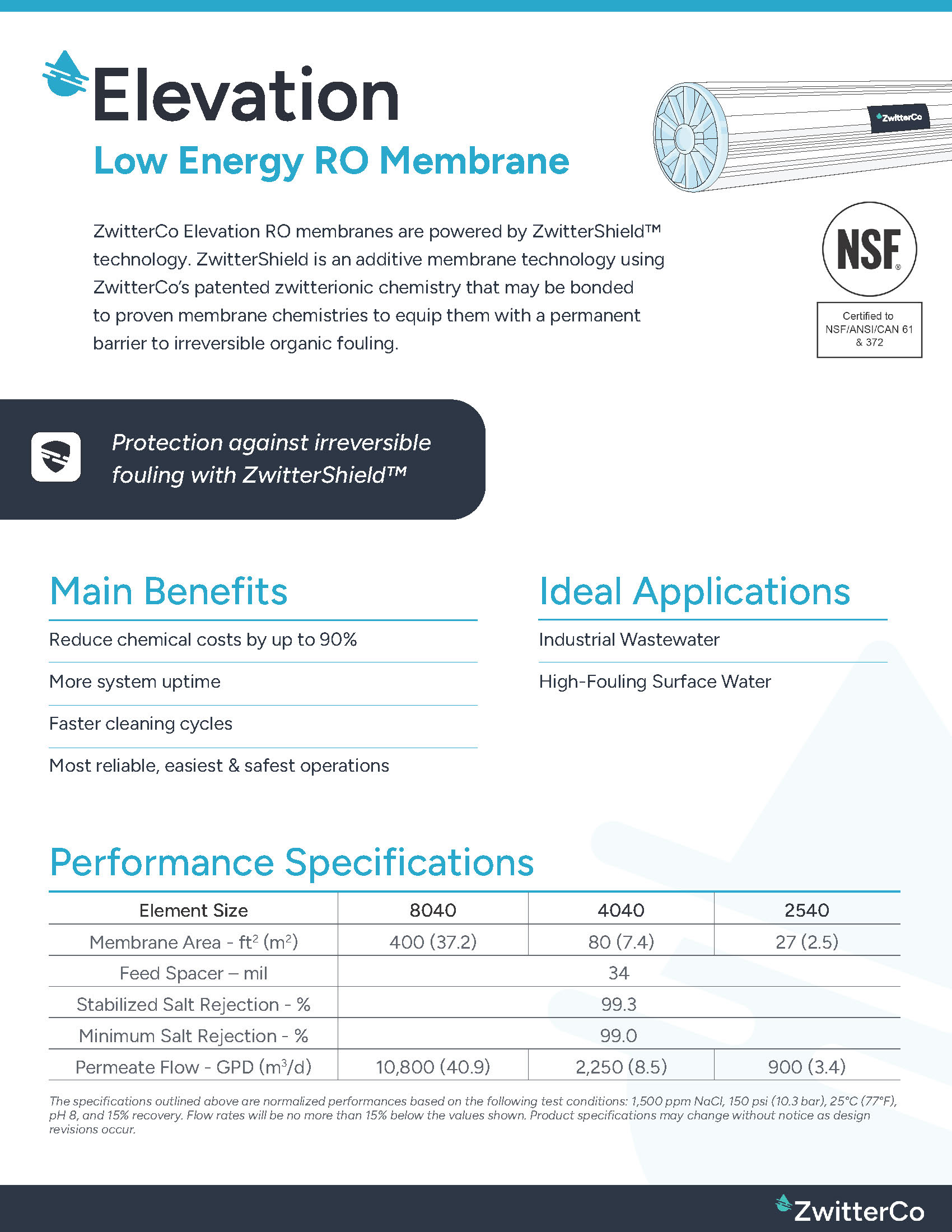

Elevation Low Energy BWRO Data Sheet

September 15, 2024Resources Page,Elevation,ElevationResource page,Data Sheet,Data Sheet

Elevation Low Energy BWRO Data Sheet

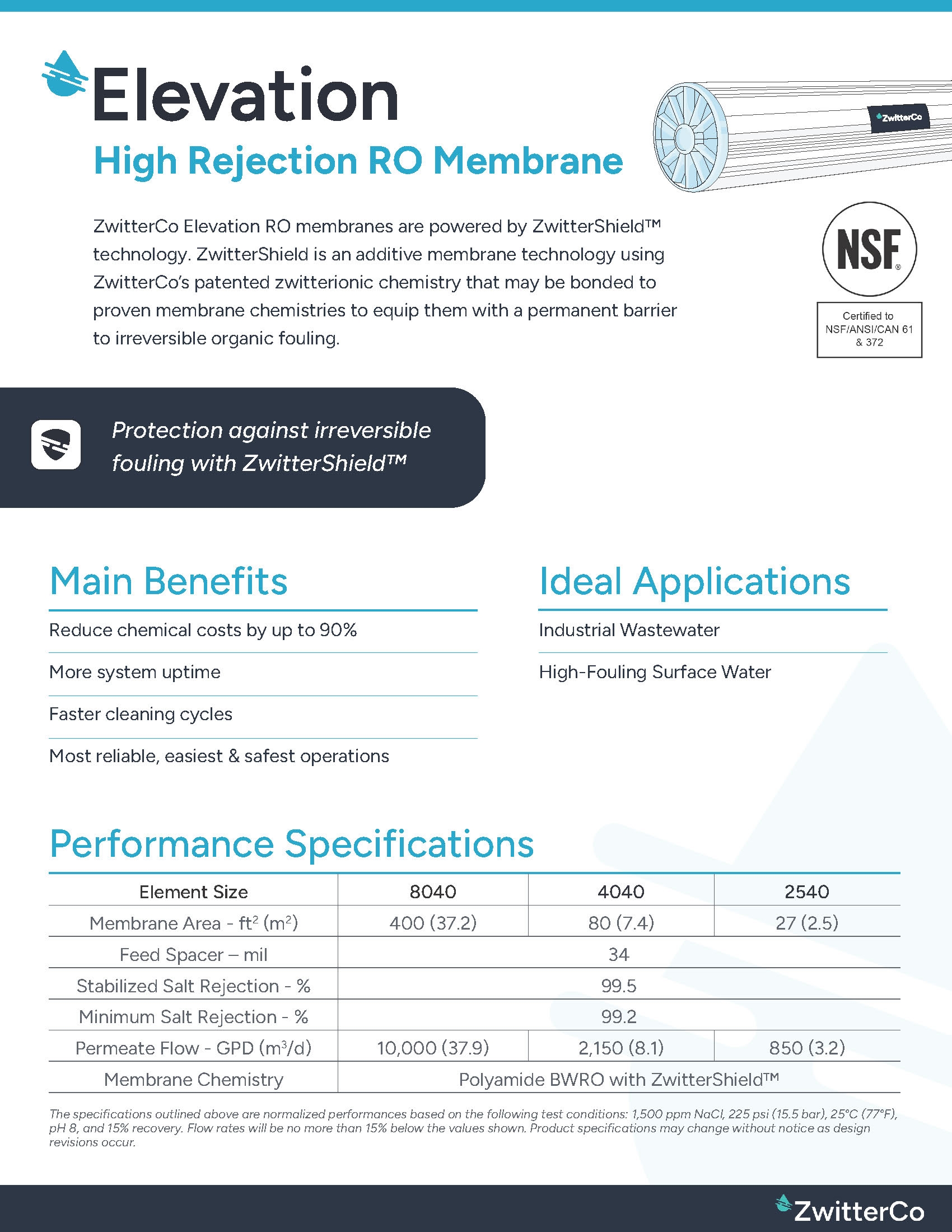

Elevation High Rejection BWRO Data Sheet

September 15, 2024Resources Page,Elevation,ElevationResource page,Data Sheet,Data Sheet

Elevation High Rejection BWRO Data Sheet

Evolution 1812 Test Elements Data Sheet

September 15, 2024Resources Page,Evolution,Resource pageEvolution,Data Sheet,Data Sheet

Evolution 1812 Test Elements Data Sheet

PFAS Removal in Landfill Leachate: The Effectiveness of RO Membranes

September 12, 2024Blogs,Industrial Wastewater,Landfill Leachate

As landfill operators face increasingly stringent regulations and growing public concern over water quality, the challenge of managing per- and polyfluoroalkyl substances (PFAS) in leachate has become a critical focus. Reverse osmosis (RO) membranes…

Regulatory Compliance in Landfills: How RO Membranes Tackle the Fouling Challenge

September 9, 2024Blogs,Industrial Wastewater,Landfill Leachate

Landfill leachate is a liquid that forms when rainwater flows through waste in landfills, picking up harmful substances like heavy metals, ammonia, and chemicals along the way. If not properly treated, it can contaminate nearby water sources and…