Water is a vital resource, and managing it responsibly is more important now than ever.

Four billion people — almost two thirds of the world’s population — experience severe water scarcity for at least one month each year. As early as 2025, half of the worlds population could be living in areas facing water scarcity.

One approach gaining traction is Zero Liquid Discharge (ZLD), a process designed to eliminate all liquid waste from a system. Let’s dive into what ZLD is, how it works, and why it’s becoming a critical component in water management practices.

Understanding Zero Liquid Discharge (ZLD)

Zero Liquid Discharge (ZLD) is a strategic wastewater management system that aims to eliminate any liquid waste discharge from industrial processes, ensuring that all wastewater is treated, purified, and reused. To do this, ZLD systems use a series of treatment processes, including superfiltration or ultrafiltration, reverse osmosis, and evaporation.

This advanced technique plays a key role in sustainable water management, especially in regions facing water scarcity and increasingly strict environmental regulations. By treating and reusing wastewater to the point where only solid waste remains, ZLD systems help industries achieve sustainable water management goals.

Key Components of a ZLD System

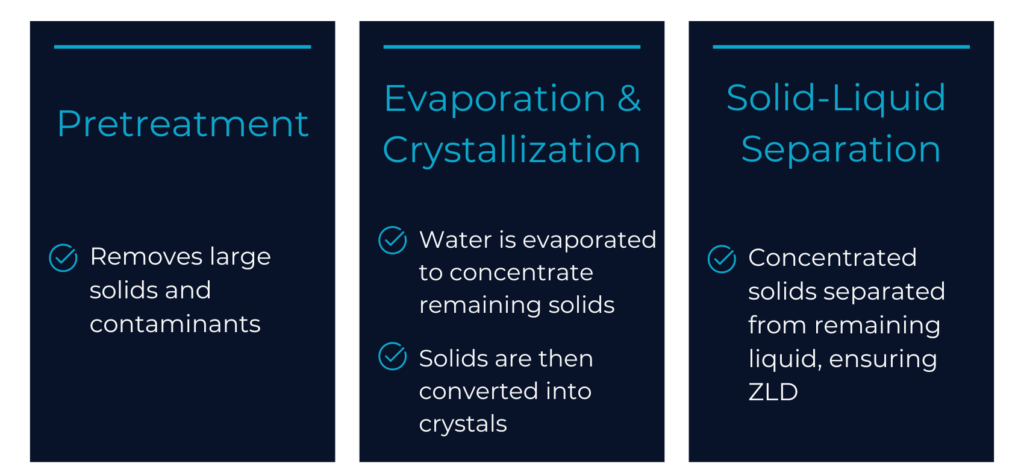

A ZLD system typically includes several stages:

1. Pretreatment

The pretreatment stage is the first line of defense in the ZLD process. Here, wastewater is typically filtered and treated with chemicals to remove large solids and contaminants like oils, greases, and heavy metals. In processes with superfiltration installed, chemicals may not be necessary or could be significantly reduced.

This step is important because it prevents these contaminants from complicating downstream processes. Different techniques like settling, floating, and biological treatments are used depending on the type of wastewater.

Want to ditch your biological systems? Learn how ZwitterCo membranes can transform your wastewater operations.

2. Concentration

After pretreatment, the wastewater goes to the concentration stage. Here, the water is usually sent to a reverse osmosis system, which produces a purified stream that can be re-used on site, such as in boiler system, and a highly concentrated reject stream. This reject stream is then sent to an evaporator, which uses heat to turn water into vapor, leaving behind a higher concentration of dissolved and suspended solids.

This step reduces the volume of liquid, making it easier to handle. The evaporated water, now free of most contaminants, can be condensed and reused within operations, conserving freshwater resources.

3. Crystallization

In the crystallization stage, the concentrated liquid is heated further to turn dissolved solids into solid crystals. These crystals are then collected and removed. This step helps manage solid waste and can also recover valuable materials from the wastewater, which can be reused or sold, adding an economic benefit to the ZLD process.

4. Solid-Liquid Separation

The final stage in the ZLD process is separating the remaining liquid from the solid waste. To do this, methods like centrifugation, filtration, or settling are typically used. The solid waste is then collected and either disposed of or processed further. The minimal amount of separated liquid can be recycled back to the start of the ZLD process. This step ensures that the ZLD system meets its goal of discharging zero liquid waste.

Benefits of Zero Liquid Discharge

ZLD systems provide numerous advantages for both the environment and industry. Some of the key benefits include:

Environmental Benefits

ZLD systems are great for the environment and offer significant benefits. By eliminating liquid waste discharge, they protect our water resources from contamination and help maintain a balanced ecosystem. This not only reduces the environmental footprint of industries but can also help them comply with stringent discharge limits and regulations.

Cost Savings

Using ZLD can also lead to cost savings. By reusing water, industries use less fresh water and have lower waste disposal costs. Over time, the money saved on water and waste management can make up for the initial investment in ZLD technology.

Applications of Zero Liquid Discharge

ZLD systems are very versatile and can be applied in various industries to manage wastewater more effectively. Both industrial and municipal applications benefit from ZLD systems, helping to reduce environmental impact and promote sustainability.

Industrial Applications

Industries like power plants, chemical factories, and textile mills generate significant amounts of wastewater. ZLD systems help these industries manage their waste more sustainably and economically by recycling and reusing water, reducing environmental harm, and complying with discharge limits to avoid fines.

Municipal Applications

Cities and municipalities can also use ZLD systems for wastewater treatment. By adopting ZLD, municipalities can cut down on pollution, save water, and support sustainable urban growth.

The Hurdles of ZLD

While ZLD systems offer many benefits, they also come with their fair share of challenges. From high energy consumption to varying costs and feasibility, it’s important to understand these factors before integrating a ZLD system.

Energy Consumption

One of the biggest challenges of ZLD systems is their high energy consumption. Traditional methods of evaporation and crystallization can be energy-intensive, leading to increased OPEX and harmful environmental impact. Newer evaporator technologies can utilize waste heat from other unit processes within the facility to reduce these energy costs.

Although the energy consumption might seem daunting, new membrane technology is making a big difference. Using these advanced membranes has many advantages, including lowering the flow sent to evaporators, which in turn cuts down on the energy required for the separation processes.

Cost and Feasibility

The cost and practicality of implementing ZLD systems can vary widely depending on the specific application. For example, wastewaters that are laden with dissolved solids and organics can be difficult to concentrate prior to evaporation. Initial setup costs can be high, and the energy-intensive requirements of traditional systems can add to operational expenses.

However, with the advent of advanced membrane technology, the feasibility of ZLD is improving. Modern membranes offer organic fouling immunity and increased clean water recovery rates, reducing the frequency of replacements and protecting downstream concentration steps such as reverse osmosis or evaporation. This results in reduced capital and operating expenses.

Zero Liquid Discharge is a powerful tool in sustainable water management. By eliminating liquid waste, ZLD systems protect our water resources, reduce environmental impact, and offer potential cost savings. Though ZLD systems are not without challenges, advanced membrane technology is paving the way for more energy-conscious, sustainable, and efficient solutions to achieve zero liquid discharge.

By adopting ZLD systems, we can better protect our water resources, reduce waste, and contribute to a more sustainable future. It’s time for industries and cities to consider ZLD as a key component in their water management strategies.