The global energy crisis is worsening, with demand increasing faster than supply and prices soaring. In 2021, global energy demand rose by 4.6%, almost twice the growth seen the previous year, according to the International Energy Agency (IEA). The price of natural gas also jumped by more than 100% in many areas, impacting economies worldwide. These issues are further complicated by supply chain problems, raising concerns about the availability and affordability of energy.

Energy in Water and Wastewater Treatment

In water treatment operations specifically, the search for energy efficiency is more critical than ever. Industries worldwide are under increasing pressure to reduce energy consumption and minimize environmental impacts. Between 2018 and 2022, the price of electricity for non-household consumers in the EU increased nearly 80% from €0.14 to €0.25. In fact, the European energy crisis has seen gas, coal, and electricity prices reaching their highest levels in decades due to various geopolitical and supply chain issues. As a result, there is a growing demand for membrane technologies that require significantly less energy demand.

Advancements in membrane technology have started to tackle these critical challenges in water and wastewater treatment, where energy consumption is a growing concern. ZwitterCo, for example, has created innovative membrane solutions that enhance the efficiency of water reuse and treatment processes in an energy-efficient way. As energy costs continue to rise, with industrial electricity prices in the United States increasing by 4.3% in 2022 alone, companies are looking for ways to save money and be more sustainable – this is where advanced energy-efficient membrane technologies have started to play a key role.

Economic and Environmental Impacts

The integration of energy-efficient membrane technologies in industrial processes offers significant economic and environmental benefits. One of the most immediate economic advantages is the reduction in energy consumption, which directly translates to cost savings. Lower energy use not only decreases operational expenses but also enhances the overall financial sustainability of industrial operations. This is especially important in industries where energy costs make up a large part of the budget. Using energy-efficient solutions can help companies achieve substantial savings, freeing up resources for other investments.

From an environmental perspective, the benefits of reducing energy consumption are equally as important. Many traditional industrial processes use a large amount of energy, which leads to high greenhouse gas emissions and can cause environmental harm. By using energy-efficient water treatment technologies, industries can greatly reduce their carbon footprint, helping to combat climate change and supporting global sustainability efforts to protect the environment.

The environmental benefits extend beyond carbon reduction. Energy-efficient water treatment processes can now utilize advanced membrane technologies that minimize waste generation and optimize resource utilization. This not only creates additional revenue streams, but also helps plants meet environmental regulations and avoid fines. By proactively adopting advanced membrane solutions, companies can not only meet regulatory requirements but also establish themselves as leaders in corporate social responsibility.

Vast Applications of Energy-Efficient Membrane Technologies

The benefits of advanced membrane technologies extend far beyond just one application, offering transformative potential across various industries. In the bioprocessing industry, advanced membrane technologies play a crucial role in optimizing production processes. By reducing the need for chemicals and minimizing energy consumption, companies can significantly lower operational costs while maintaining high-quality output. This not only enhances profitability but also aligns with growing demands for sustainable and environmentally friendly practices.

In water treatment, membrane technologies are transforming both municipal and industrial applications. Industrial applications, ranging from food and beverage to pharmaceuticals, benefit from these membrane technologies by achieving higher levels of water reuse and waste reduction. This is particularly important as industries face increasing regulatory pressures and rising water scarcity challenges.

With regulations such as the EU Nitrates Directive restricting the ability to spread digestate, proper nutrient management is paramount for any new biogas project. Membrane technologies such as microfiltration and ultrafiltration have gained popularity in the digestate industry due to their ability to concentrate nutrients, reduce the volume of digestate needed to be hauled off-site, and ultimately improve the OPEX required to process digestate. However, the tubular membrane designs often used in this process carry heavy energy requirements.

Energy Efficiency in Digestate Treatment

Anaerobic digestion (AD) is a key process in digestate treatment, converting organic waste into biogas, a renewable energy source. The efficiency of AD processes is directly linked to energy savings, as improved efficiency reduces the energy required for treatment and maximizes biogas production.

Digestate, a byproduct of anaerobic digestion processes, presents unique challenges for treatment due to its high solid content and complex composition. Common membrane configurations, such as tubular membranes, often face challenges such as high energy consumption and fouling. The open channel configuration of tubular membranes relies on large pumps to create the horsepower and fluid turbulence needed to maintain sufficient crossflow. These issues can lead to increased operational costs and maintenance needs. However, recent advancements in membrane technology, particularly the development of spiral configurations, have revolutionized this process.

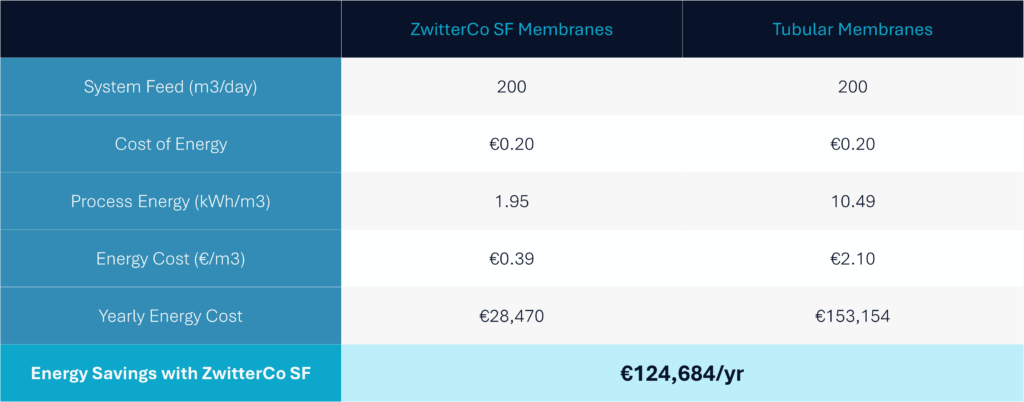

For example, data comparing energy consumption between traditional tubular membranes and ZwitterCo advanced superfiltration (SF) spiral membranes in digestate treatment revealed substantial energy savings with the latter. In contrast to tubular membranes, which require high cross flow velocities and high electrical demands, the spiral configuration of ZwitterCo SF membranes has a high packing density and requires significantly less energy to maintain smooth operations. The estimated energy consumption for ZwitterCo membranes in digestate applications is expected to be in the range of 2kWh/m3 of permeate, compared to 10kWh/m3 for tubular configurations.

*Assumed performance based on similar applications and operating parameters

*Assumed performance based on similar applications and operating parameters

Energy Saving Benefits of ZwitterCo SF

Lower Crossflow Rates

ZwitterCo SF spiral membranes operate at lower crossflow rates than traditional tubular membranes, saving energy and reducing equipment wear and tear.

Reduced Cleaning Frequency

Most ceramic membranes require many chemically enhanced backwashes and CIPs to restore performance. However, with high fouling resistance, ZwitterCo SF offers easy and simple cleaning cycles, conserving energy and maximizing system uptime.

Efficient Solids Removal

ZwitterCo SF removes dissolved and suspended compounds larger than 1 nanometer/1 kDa molecular weight, providing ideal feedwater to reverse osmosis. This reduces energy use in downstream processes and improves overall water treatment efficiency.

The journey towards energy-efficient industrial processes is an ongoing one, and membrane technologies are proving to be a key component. These advanced technologies, used in everything from digestate treatment to a wide range of other applications, offer significant energy savings and environmental benefits. To remain competitive and sustainable, industries must keep up with the latest advancements. As industries continue to search for sustainable solutions, the adoption of advanced membrane technologies will be key to achieving these goals.