Zwitterions are gaining attention across industries for their remarkable ability to resist fouling, enhance biocompatibility, and maintain clean, functional surfaces in challenging environments. While ZwitterCo has pioneered the use of zwitterionic chemistry in membranes, the same molecular principles are unlocking breakthroughs in fields ranging from medicine to advanced materials. This blog is part of a series that explores how zwitterions are being applied far beyond water treatment and reshaping innovation in medical implants, drug delivery, and antifouling surfaces.

Redefining Biocompatibility and Performance

In the rapidly evolving world of biomedical engineering, ensuring that medical devices can safely and effectively integrate with the human body is paramount. From heart valves and stents to orthopedic implants and catheters, one of the most persistent challenges has been biofouling—the unwanted accumulation of proteins, cells, and bacteria on device surfaces. Enter zwitterions: a class of molecules that has emerged as a transformative tool for enhancing the safety, longevity, and performance of medical implants.

Zwitterions are molecules that possess both a positive and a negative charge across their functional groups, yet are overall charge balanced and therefore electrically neutral. This unique charge configuration allows them to interact favorably with water to form a tightly bound hydration layer, creating a highly hydrophilic surface that resists interactions with organic or biological materials. Unlike traditional coatings like polyethylene glycol (PEG), zwitterion-incorporated surfaces are stable, non-toxic, and offer long-term performance in physiological environments.

Enhancing Implant Safety and Function

One of the most critical applications of zwitterionic materials is in vascular implants, such as artificial heart valves and stents. Research from the University of Sydney has shown that zwitterion-based surface treatments can significantly reduce protein adsorption and platelet adhesion—two key factors in clot formation. By resisting the initial fouling that triggers thrombosis, these coatings reduce the risk of device failure and improve patient outcomes without relying on long-term anticoagulation therapies.

Similarly, in orthopedic implants like joint replacements or bone screws, infections and inflammation caused by bacterial colonization remain a significant concern. Titanium implants modified with pH-responsive zwitterionic surface treatments have demonstrated enhanced resistance to biofilm formation and inflammation, while still supporting cellular compatibility and tissue integration.

Moreover, medical tubing, sensors, and catheters benefit from zwitterionic treatments by resisting protein build-up and microbial adhesion, thereby reducing the risk of infection and device-related complications during extended use.

Why Zwitterions Work So Well

The antifouling ability of zwitterions stems from their electrostatically induced hydration shell. This shell acts as a physical and energetic barrier to protein adsorption and cellular attachment, without relying on toxic biocides or sacrificial degradation. This property is particularly important for implants that must remain in the body for years—or even decades—without degrading or losing performance.

In addition to their biocompatibility, zwitterionic materials are tunable. Researchers are developing “smart” zwitterionic coatings that respond to stimuli like pH or temperature, further customizing how implants behave in different regions of the body.

ZwitterCo: Bringing Zwitterions to Water Treatment—and Beyond

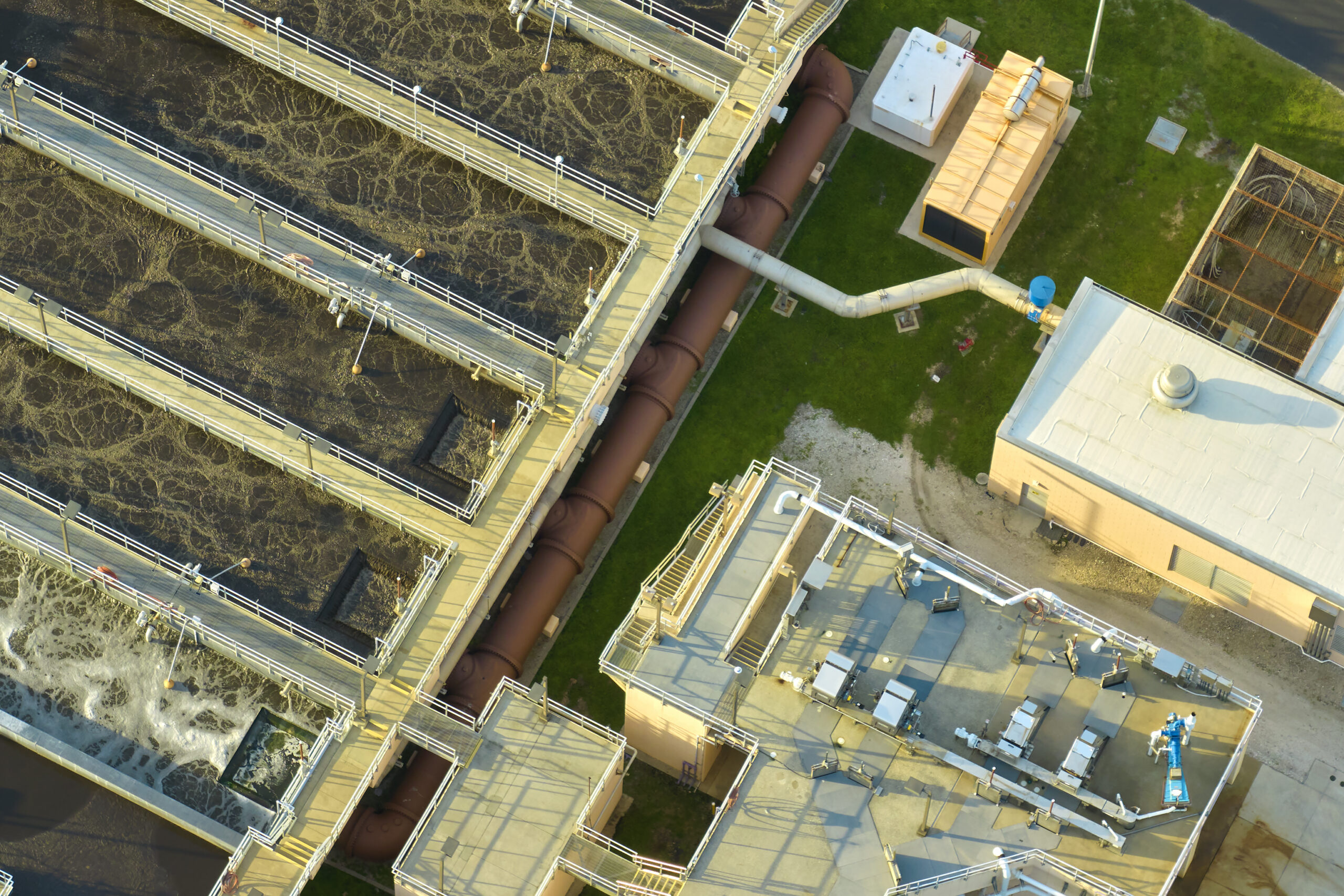

At ZwitterCo, we have harnessed the power of zwitterionic chemistry to revolutionize water and wastewater treatment. Our membranes are made from proprietary zwitterionic copolymers that provide unparalleled resistance to fouling from organic compounds like fats, oils, greases, and proteins—materials that traditionally clog and degrade conventional membranes.

Just as zwitterions extend the life and performance of medical implants by preventing biofouling, our membrane technology does the same for industrial filtration. By resisting irreversible fouling, our membranes maintain high flux and require fewer cleanings, reducing operating costs and increasing uptime.

While our core mission is solving wastewater challenges, we are part of a broader movement that is proving the extraordinary value of zwitterionic materials across disciplines—from healthcare to biotechnology and beyond.

The future of high-performance, low-fouling technology is zwitterionic. At ZwitterCo, we’re proud to be leading the charge.