ZwitterCo Unfiltered Recap | Ep 1: Why “Lower Clean Water Flux” Can Still Mean Higher Throughput (and Easier Cleaning)

ZwitterCo just launched ZwitterCo Unfiltered – a new podcast series focused on real-world membrane performance, customer questions, and field experience. Episode 1, hosted by Jon Goodman (VP of Food Processing & Specialties, ZwitterCo) and Scott…

How a Midwestern Dairy Stabilized Its Flush Water System with Evolution RO

Reverse osmosis systems play a critical role in dairy processing operations, particularly when treating CIP flush water from cleaning milk processing equipment. When these systems become unstable, the impact is felt quickly – through rising…

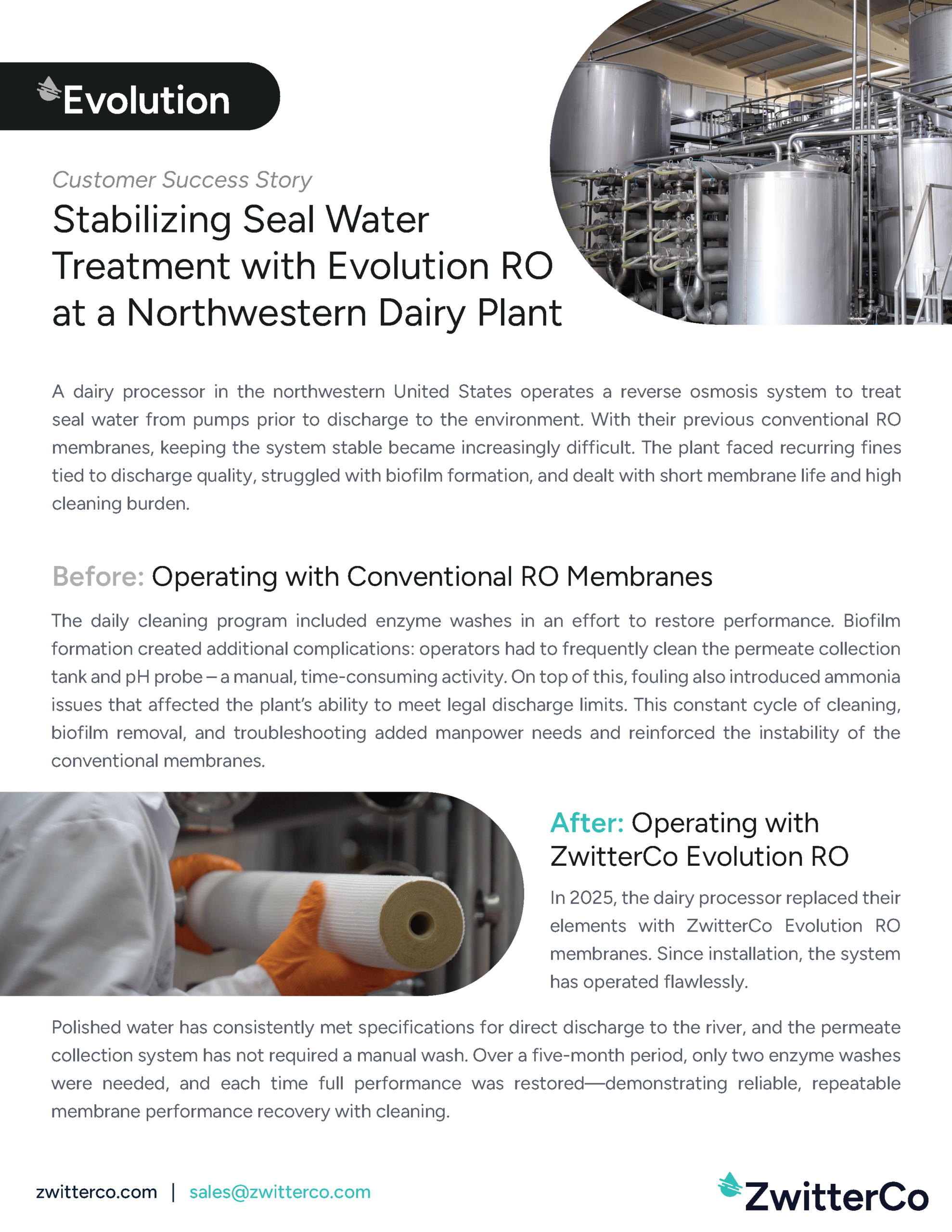

Stabilizing Seal Water Treatment with Evolution RO at a Northwestern Dairy Plant

For dairy processors discharging utility water to the environment, system stability isn’t optional – it’s the difference between compliant operation and recurring fines. One dairy processor in the northwestern United States experienced this…

A New Standard for UF Milk Concentration

Operating flux during milk concentration is primarily shaped by the gel layer – the dynamic barrier that naturally forms on the membrane surface as product is concentrated. This gel layer develops because protein, fat, and other retained solids…

A More Productive Path to WPC35: Faster Cleaning, Higher Flux

Why Evolution Protein Concentration Membrane (PCM) Is Raising the Productivity Bar in WPC35 WPC35 concentration is typically designed for reliability and consistency, with operating conditions that allow conventional UF membranes to run smoothly…

Cutting the Enzyme Cleaning Step with Anti-fouling Membranes

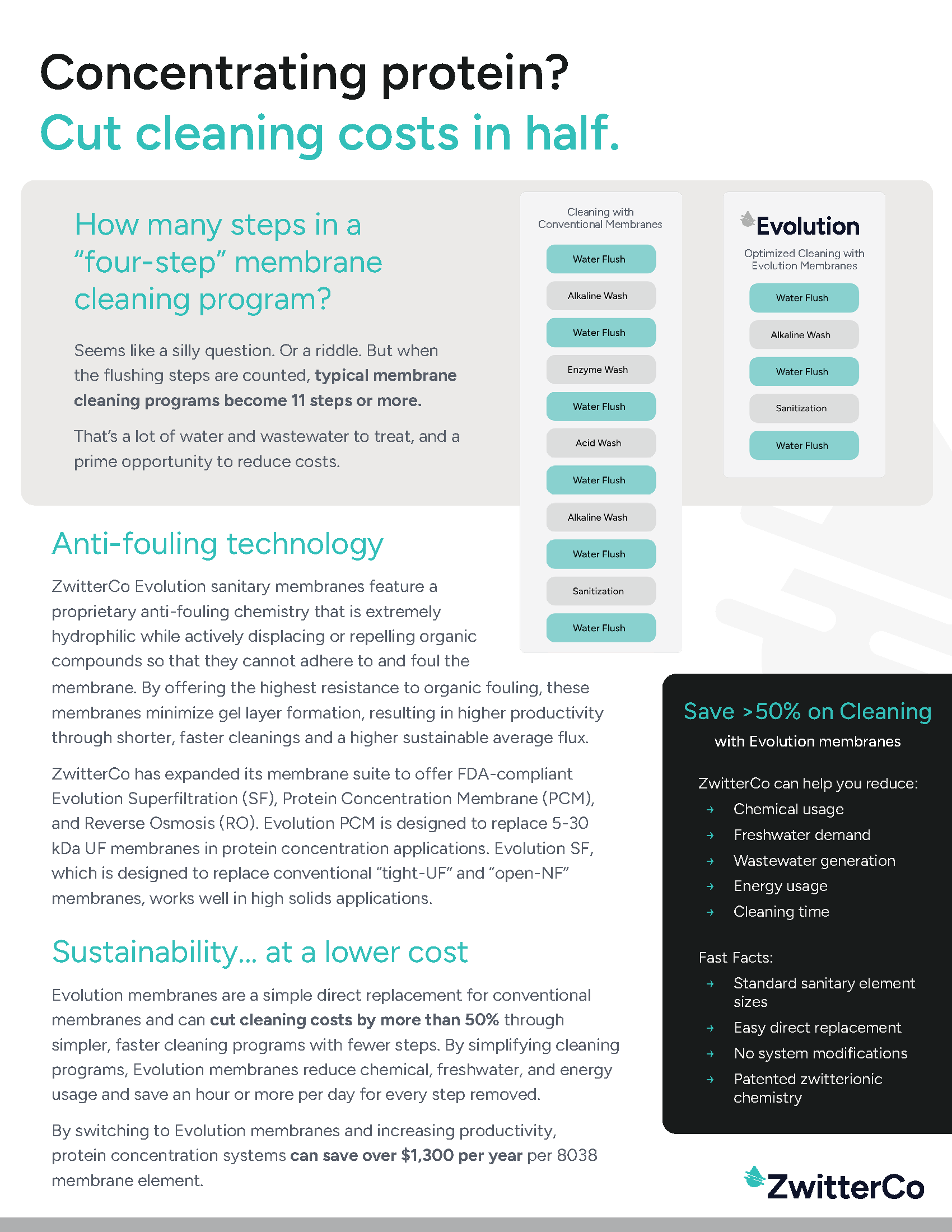

Every cleaning step in a membrane system takes time, water, chemicals, and energy. For many processors, enzyme washes are the most expensive of all. ZwitterCo Evolution membranes can remove one or more cleaning steps – including the enzyme step – to…

Closing the Loop on Process Water

Across the food and beverage industry, water reuse has shifted from a sustainability aspiration to an operational requirement. Rising discharge costs, tightening regulations, and the ongoing pressure to reduce water intensity have made reuse a…

ZwitterCo Achieves FDA Compliance for Evolution RO and PCM Membranes, Expanding Capabilities for Whey and Milk Processing

Woburn, MA – Nov, 5, 2025 | ZwitterCo, a global leader in membrane solutions for challenging liquid separations, today announced that its Evolution Reverse Osmosis (RO) and Protein Concentration Membrane (PCM) products are now FDA-compliant for whey…

Making Downstream Processing More Economically Feasible

Downstream processing (DSP) in fermentation and enzyme operations involve separations that are ideal for membranes. Unfortunately, conventional membranes in DSP often fight a losing battle against fouling. Every time flux drops, cleaning length and…

Improving WPC80 and WPI90 Operating Efficiency with Evolution SF

Achieving high protein concentrations in WPC80 and WPI90 processing has traditionally required a tradeoff between solids and flux. Proteins and other organics tend to adhere to conventional polyethersulfone membranes, so as solids increase, the…

Evolution Anti-Fouling Membranes: Applications & Regulatory Status

Q: Is there a white paper that outlines the data shown regarding “cost savings of 50%” and “using 40% less water?” A: Yes, there is a case study on our website showing this data from a US-based whey processor using Evolution RO to concentrate…

Evolution Anti-Fouling Membranes: Technology and Product Details

Q: What are the operating pressure limits for Evolution membranes? A: Evolution membranes are designed to be direct replacements for conventional sanitary membranes and are designed to have the same pressure limits. Pressure is mainly a function of…

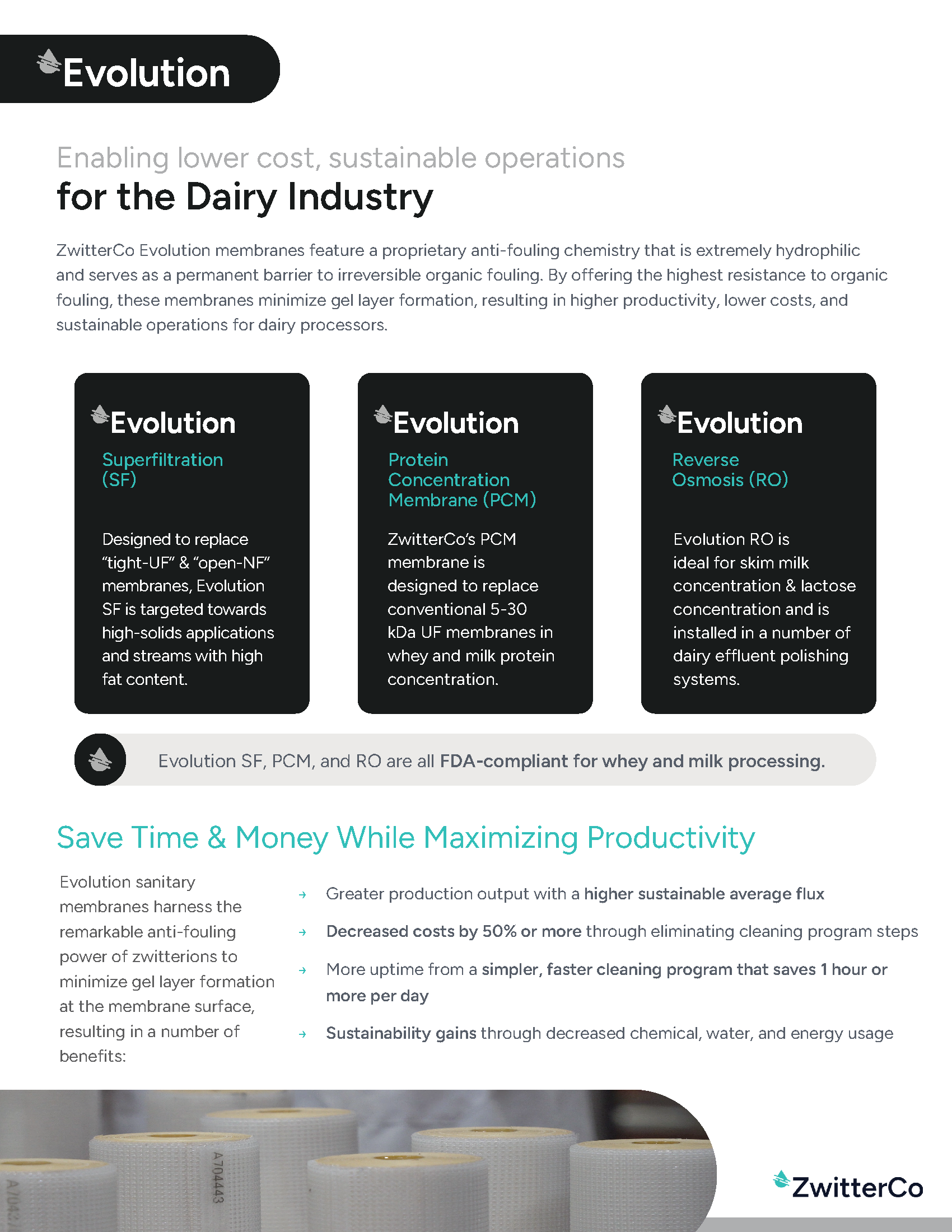

Anti-Fouling Membranes: The Next Evolution in Dairy & Food Processing

Dairy and food processors face continuous pressure to improve operational efficiency, reduce costs, and meet ambitious sustainability targets. ZwitterCo’s Evolution sanitary membranes provide the breakthrough solution processors have been waiting…

ZwitterCo Launches Evolution Membranes, Transforming Dairy and Food Processing Efficiency

Woburn, MA – Sept. 4, 2025. | ZwitterCo, a global leader in membrane solutions for challenging liquid separations, has announced the commercial release of its Evolution membrane product family. These next-generation membranes are engineered to help…

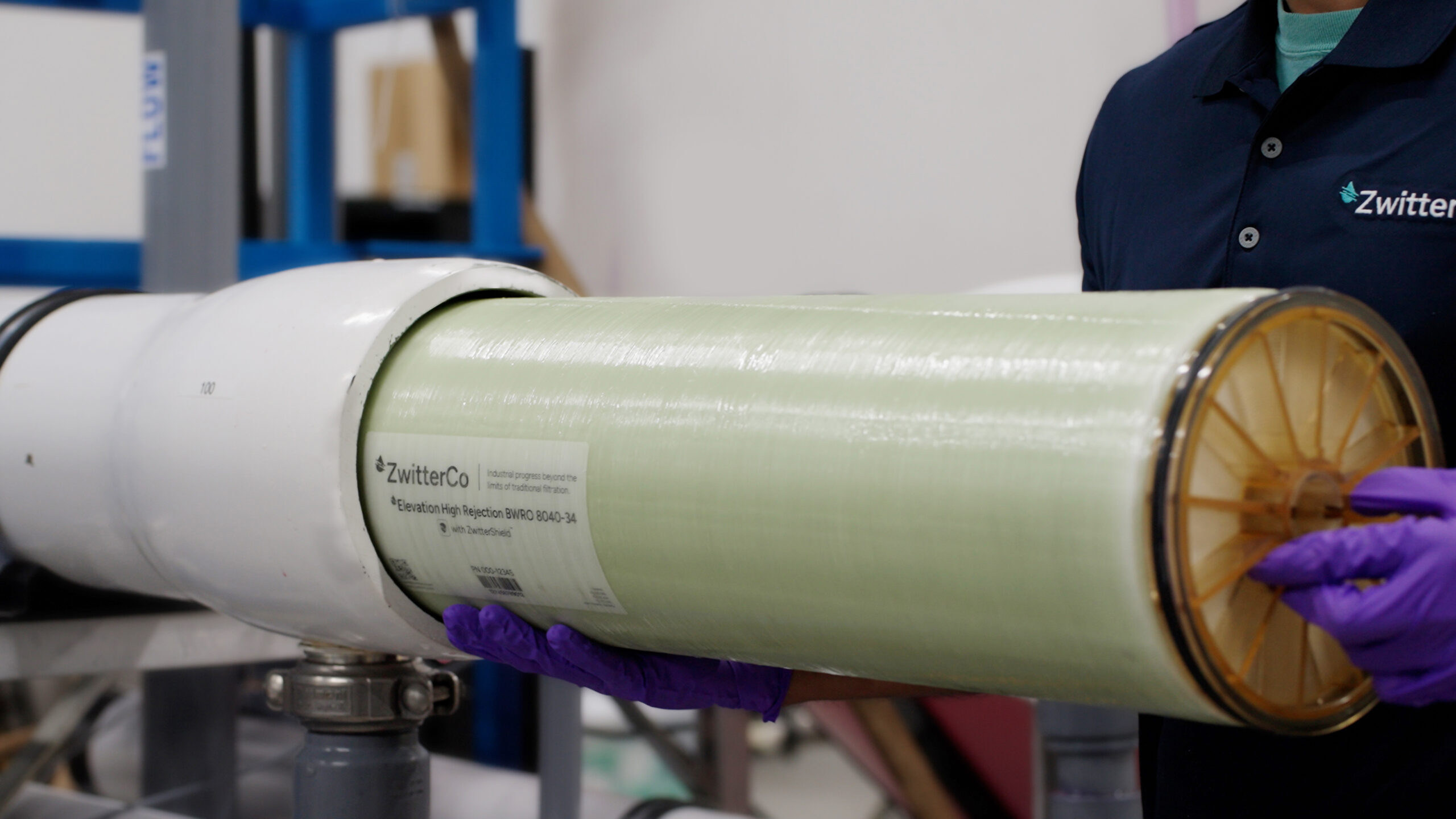

ZwitterCo Expands Portfolio of the Industry’s Most Fouling-Resistant Membranes with Elevation, Evolution, and Expedition

Introducing a new era of sustainable membranes for food processing and industrial water reuse & wastewater treatment Woburn, MA – July 23, 2025. ZwitterCo, a global leader in advanced membranes for challenging separations, has unveiled three…

ZwitterCo™ Introduces New FDA Compliant Anti-Fouling Membranes for Whey Processing

Originally posted by FoodBev Media WOBURN, Mass., | April 14, 2025 – ZwitterCo is proud to announce the availability of a new product line of sanitary superfiltration (SF) spiral membrane elements featuring its second-generation SF technology.…

The Price of Performance: Understanding Dairy Membrane Costs

Membrane technology has become indispensable in the dairy industry, enabling processes from milk concentration to whey fractionation. Despite their many advantages, membrane systems come with a variety of operational costs: high specialty chemical…

Lower Costs, Less Hassle: How Two Dairy Processors Improved Their Wastewater Treatment

Lower Costs, Less Hassle: How Two Dairy Processors Improved Their Wastewater Treatment Two whey processing facilities were operating as usual—regular membrane cleaning cycles, chemical costs adding up, and normal membrane replacements due to wear…

Evolution Product Introduction Webinar

WEBINAREvolution Anti-fouling Membranes: The Next Evolution in Food, Dairy, and Biotech Processing

How Solugen, A Bioprocessing Manufacturer, Increased Efficiency with ZwitterCo

Download Case Study Case Study: The Impact of ZwitterCo Membranes at Solugen Solugen, a leading biotech and clean technology company, has revolutionized the chemical industry through its innovative chemi-enzymatic processes. Their…