The only membranes that concentrate valuable FOG and protein, reuse water, and recover anti-microbial chemicals.

Meat & Poultry wastewater, as well as process effluents derived from scald tanks, IOBWs, chillers, and other processing steps, are rich with residual fats, oils, greases (FOG) and proteins. These organic compounds increase the cost and complexity of wastewater management, as conventional treatment solutions:

- Do not repurpose the organics as valuable brown or yellow grease

- Do not recover water or unspent anti-microbial chemicals like PAA or chlorine

- Require coagulation and flocculation chemicals to remove organics before discharge, resulting in expensive and troublesome sludge disposal

- High potential to exceed discharge standards, resulting in surcharges and potential non-compliance risk

Membrane technologies are the ideal tools to capture and concentrate valuable organics without chemicals, purify water and unspent anti-microbial chemicals for reuse, and achieve the highest quality of treated effluent. Organic fouling has historically prohibited membranes from being usable in meat and poultry applications, but ZwitterCo’s membranes have unprecedented fouling resistance and upend historical restrictions on filtering organic-heavy streams, making new wastewater and effluent recycle solutions practical.

Fouling resistant membranes built for the FOG and protein in meat & poultry effluent

Meat & Poultry Solutions

Are you looking to recover water, anti-microbial chemicals, or valuable organics during production?

Are you looking to improve wastewater discharge quality, reduce costs, and eliminate chemistry?

Anti-Fouling, Sanitary Membranes for Food Processors

Membranes Built with ZwitterCore™

Membranes built to handle up to 5% FOG and protein

>99% removal of FOG and bacteria; < 1% removal of PAA

Compact, automated, and designed for food-safe applications

Enable Treatment and Reuse of the Toughest Wastewater and Process Streams

Membranes Built with ZwitterCore™

Membranes built to handle up to 5% FOG and protein

>99% removal of FOG, Turbidity; 70-90% removal of COD

Compact, fast to implement, and no chemical or biological upsets

Chemical-free concentration of FOG and protein

Concentrate More. Dose Less.

During filtration, any compounds that are rejected by the membranes are captured and concentrated without relying on in-line coagulant or flocculant dosing. In a meat and poultry applications, ZwitterCo’s membranes can concentrate FOG and protein to 20x their initial concentration or higher. This has the two-fold benefit of:

Sanitary-style membrane system

- Successfully removing organics at a substantially lower operating cost, as no continuous chemical dosing is required. This can occur during production (i.e., at the IOBWs or chillers) to take organic load off of downstream wastewater operations or during wastewater treatment to ensure discharge compliance.

- Creation of a chemical-free FOG and protein concentrate stream that can be upgraded into valuable feedstocks. Once concentrated, the FOG and protein can be heated (so the fat, oil, and solids separate) and decanted to extract sellable yellow grease and brown grease byproduct streams.

(left to right) IOBW process water, SF permeate, SF concentrate

Did you know?

Salmonella and E-Coli bacteria measure between 0.7 – 1.5 microns and 0.25 – 1.0 microns on their narrowest dimensions. SF membranes have 1 nanometer pores, meaning that they remove compounds 100x smaller than a bacteria cell.

Recycle water and PAA during production

Save chemistry. Reuse water.

Evolution SF membranes can remove >99% of FOG, protein, and bacteria out of process water while removing < 1% of unreacted anti-microbial chemicals like PAA or chlorine. This enables the capture and reuse of process water and residual anti-microbial chemistry before these streams reach the floor drains. Ideal processing steps include:

- Inside out bird washers (IOBW)

- Chillers

- Parts-chillers

- Other process steps with heavy water and anti-microbial chemical use

By continuously filtering the water in chillers, scald tanks, and other production steps that hold large volumes of water, processors can improve the efficacy of antimicrobial chemicals and minimize the accumulation of organic contaminants and bacteria. Preventing the accumulation of bacteria during production can help processors make enormous gains on their health and safety goals.

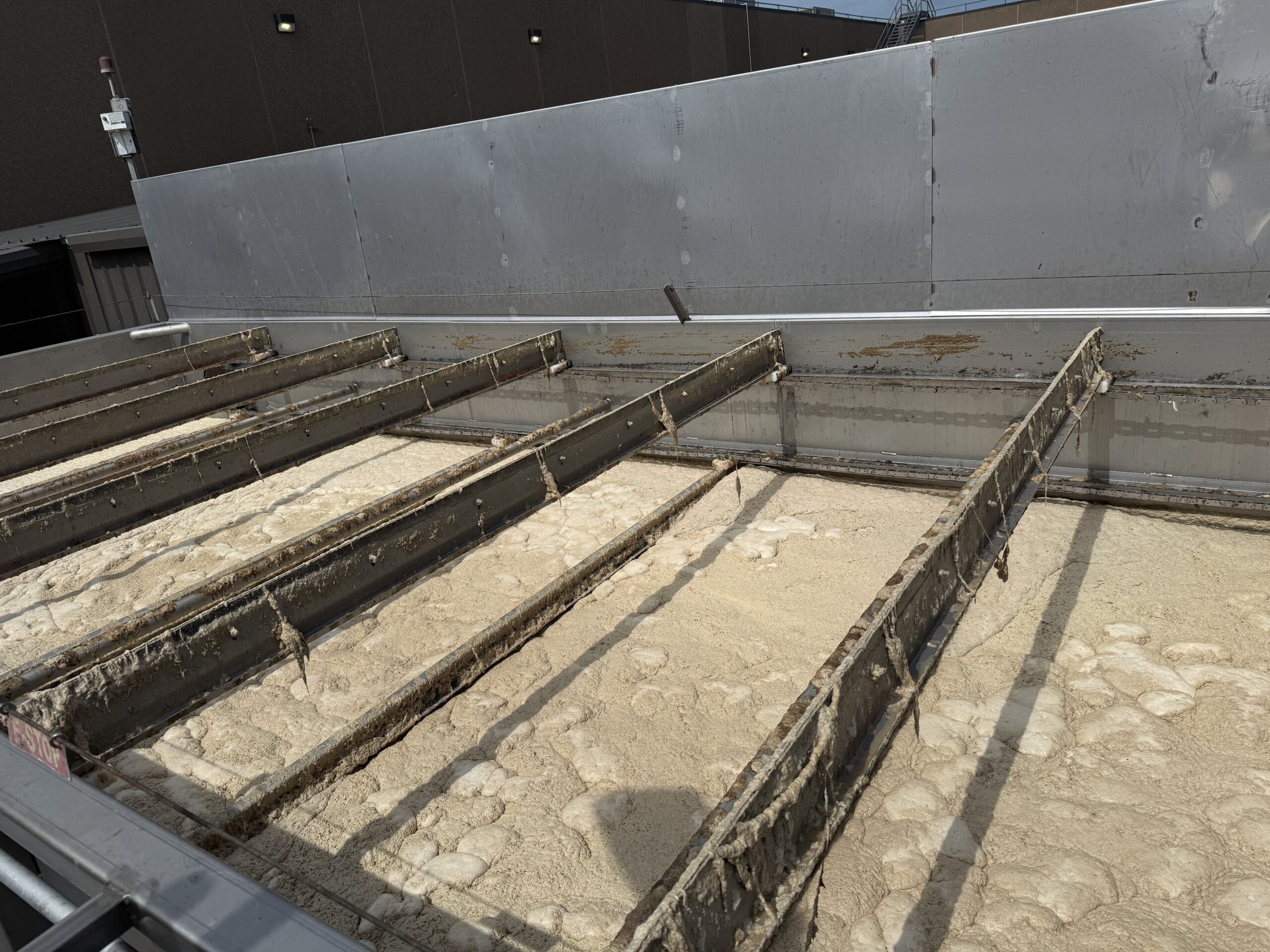

Eliminate DAF chemistry and chemical-laden sludge disposal

DAF without the dose.

When Expedition SF membranes polish DAF effluent, meat and poultry processors can eliminate the use of coagulation and flocculation chemistry in their DAF. The DAF can operate in “air-only” mode to remove fat, oil, and larger solids that naturally float or settle, letting the membranes remove contaminants larger than 1 nanometer.

The DAF float and membrane concentrate, which contain valuable fat, oil, and protein and are free of any chemicals, can be upgraded as a yellow or brown grease and converted to feed material. By finding a valuable outlet for these organics, plants can eliminate the disposal challenges that come with chemically-laden DAF sludge. This is especially important in jurisdictions that are increasing the scrutiny and restrictions around land-application of waste.

Chemical DAF common to many meat & poultry wastewater plants

(left to right) “Air-only” DAF effluent (3 different times of day), SF concentrate, SF permeate

Meet discharge requirements and eliminate surcharges

Lower Surcharges. Cleaner Water.

ZwitterCo’s Expedition SF membranes remove suspended and dissolved contaminants larger than 1 nanometer. In meat and poultry wastewater treatment, this yields:

- >99% removal of FOG

- >99% removal of TSS and turbidity

- 70-90% removal of BOD / COD

- 50-70% removal of TKN

Depending on the initial concentration, filtering wastewater with Expedition SF will minimize or eliminate discharge surcharges related to organics. It also creates opportunities for non-potable reuse (i.e., truck & floor washing, meat screen flushing, etc.) or final wastewater polishing with reverse osmosis to remove chlorides and ammonia.

WATCH

ZwitterCo's Game Changing Membrane Filtration for Meat & Poultry Processing

Discover how ZwitterCo membranes reduce chemical usage and enable water reuse in meat and poultry operations.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.