Lower operating expenses.Higher productivity.

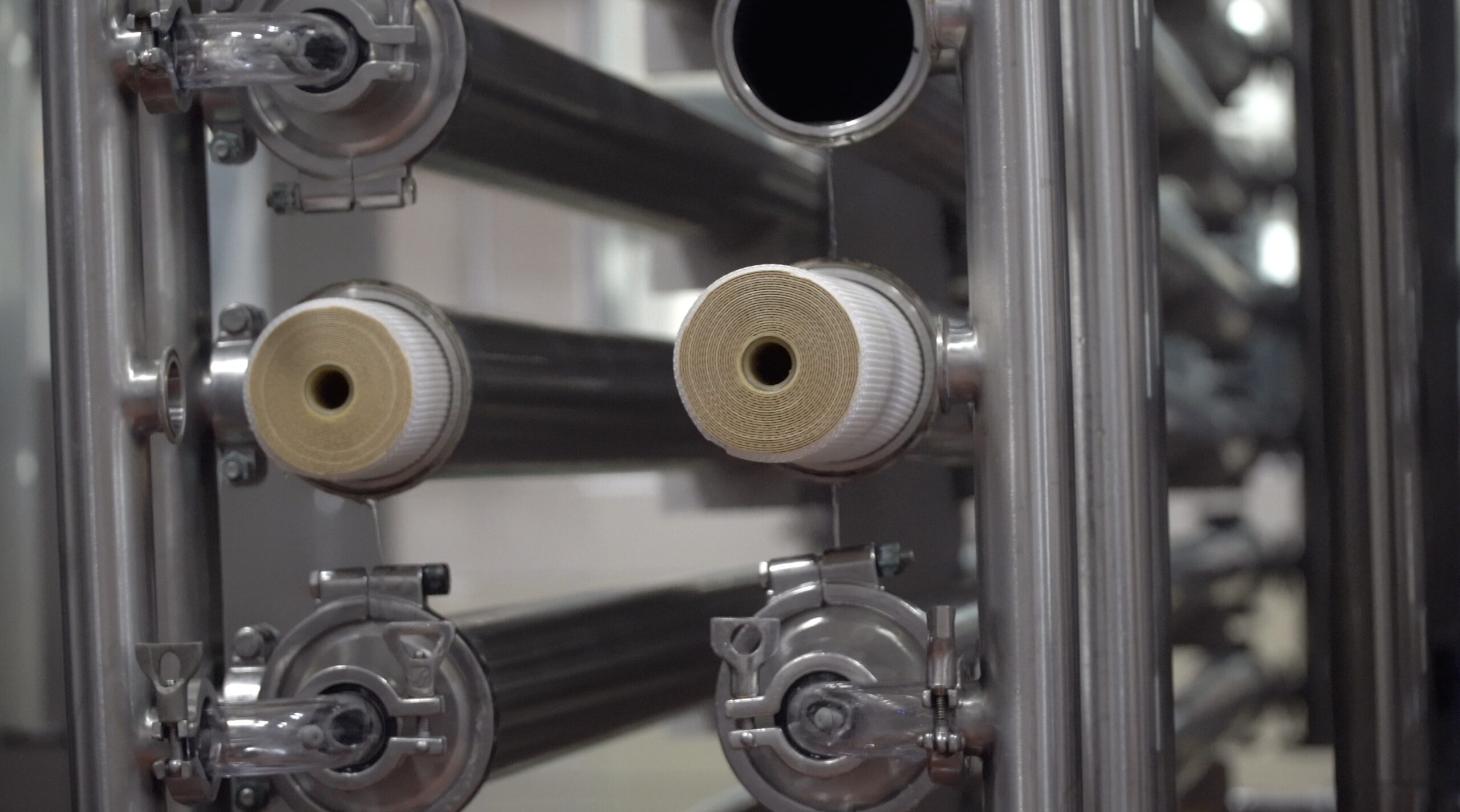

Evolution sanitary membranes handle foulants in food processing streams with ease while maintaining a higher average flux. Users save money and time while reducing chemical and freshwater usage through simpler and faster cleaning programs.

Zwitterionic Technology Unlocks Anti-Fouling Membranes for Food Processing.

Evolution membranes feature a patented zwitterionic chemistry which serves as a permanent barrier to irreversible organic fouling, making them perfect for gelatin, plasma, plant protein, starch and other food processing streams. This proprietary anti-fouling chemistry is extremely hydrophilic while actively displacing or repelling organic compounds so they cannot adhere to and foul the membrane.

These membranes offer the highest resistance to organic fouling, minimizing gel layer formation and maximizing productivity. Users benefit from a higher sustainable average flux, simpler cleaning programs, and more time for production.

What Challenges Can ZwitterCo Solve for You?

Now that we are introducing FDA-compliant products, we are ready to help you.

Plant protein concentration

Simplify Cleaning. Face Foulants.

Evolution membranes tackle organic foulants with ease while enabling easier and shorter cleaning programs. With simplified cleanings that use less energy and chemicals, users are given back one of their most valuable commodities: time.

Effluent water reuse

Reuse water and save money.

Processes like diafiltration or washing produce large quantities of water with the potential for reuse. Evolution RO membranes can polish this water with a faster and simpler cleaning program than conventional membranes can provide.

Save on operating expenses while achieving sustainability targets with Evolution RO membranes.

starch derivatives processing

Clean less, produce more.

With simpler cleaning programs than conventional membranes offer, Evolution membranes result in less time cleaning and more time producing. The easier and faster cleanings offered by Evolution membranes decrease OPEX by:

- Lowering cleaning costs

- Decreasing water usage

- Generating less wastewater

- Lowering energy requirements

gelatin concentration

Use fewer chemicals and less water.

By reducing cleaning duration with their anti-fouling chemistry, Evolution membranes save money on water and chemicals. In addition, the shorter cleaning programs allow users to gain more production time for concentrating gelatin.

Blood plasma processing

Maximize productivity with less OPEX.

Experience a higher average sustainable flux on this high fouling stream with Evolution anti-fouling membranes. Along with faster and easier cleaning programs, Evolution membranes save users money.

sugar processing

Save time and money? Sweet deal.

Evolution membranes feature a permanent barrier to irreversible organic fouling, allowing them to increase productivity in sugar processing applications. This leads to a simpler and lower-cost cleaning program that uses less chemicals and water, which can considerably support sustainability initiatives.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.