Reduce digestate volumes and future-proof your nutrient management strategy

Managing digestate is one of the most persistent and resource-intensive challenges for biogas plant operators generating renewable natural gas (RNG) from manure, food waste, liquid waste and other source separated organic feedstocks. Digestate treatment solutions must:

- Minimize liquid volumes, making it easier to store concentrated nutrients for use during ideal growing seasons and reducing the costs and logistical challenges of digestate hauling

- Meet treatment standards for environmental discharge or water recycling

- Ensure RNG plants comply with their nutrient management plans and are resilient against changes in local land application or discharge regulations

- Operate reliably, even as the composition of digestate changes seasonally and from variations in feedstock quality

- Be compact, especially for urban RNG plants with heightened space constraints

With their unprecedented fouling resistance, ZwitterCo’s membranes are the ideal tools for digestate pre-treatment or polishing, as they can operate reliably despite the high organic content present in digestate.

Quick Resources

Fouling resistant membranes built for high BOD / COD levels in digestate treatment

Digestate Solutions

Are you an existing membrane user looking to reduce costs and increase uptime?

Are you looking for a solution to reduce digestate volumes and meet discharge requirements?

Elevation membranes for leachate:

Membranes with the Highest Resistance to Organic Fouling

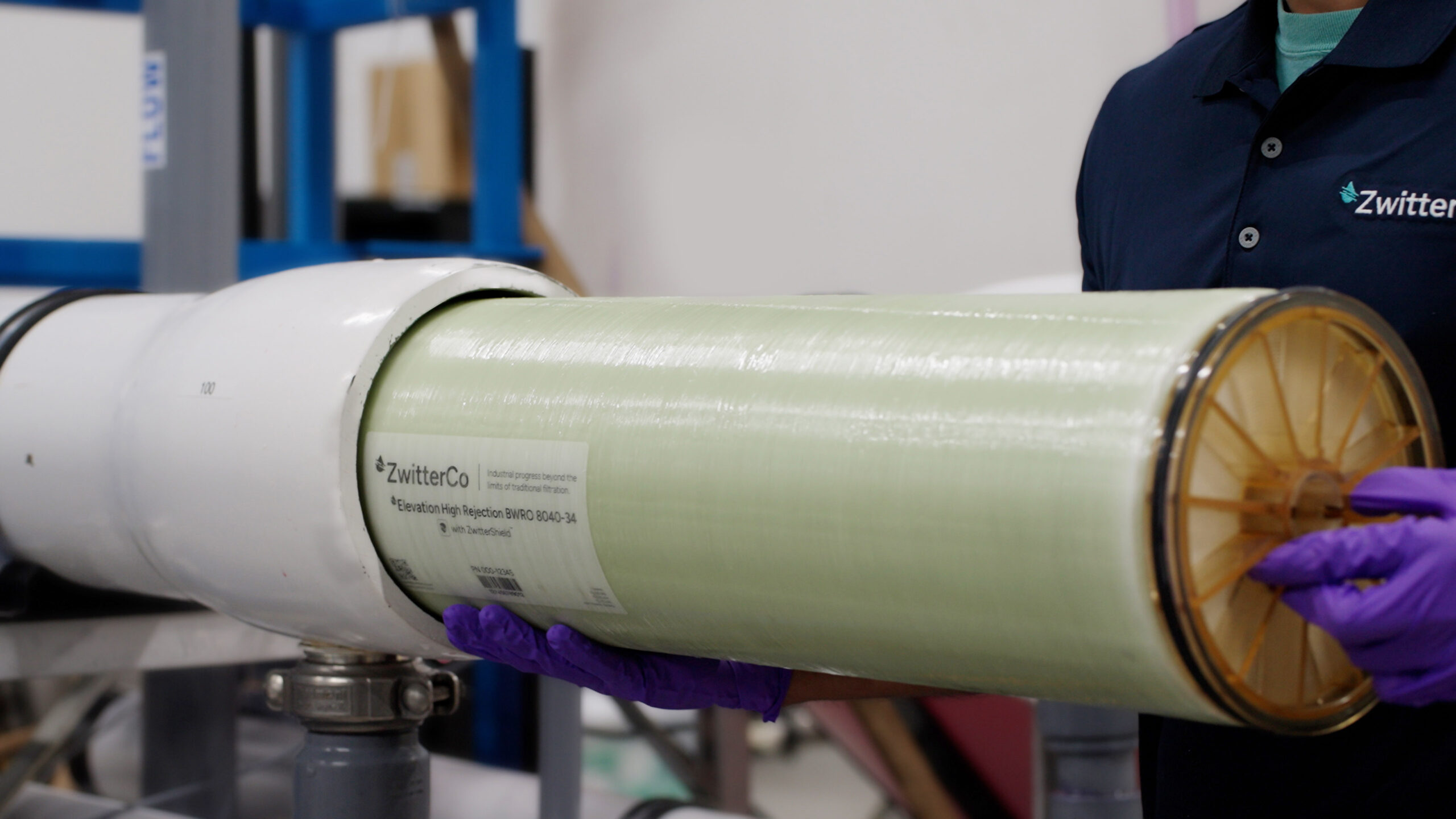

Membranes Built with ZwitterShield™

Shorten cleaning duration and extend time between cleaning cycles

Clean with simple chemicals instead of expensive, formulated cleaners

Save money with reduced membrane operating costs

Enable Treatment and Reuse of the Toughest Wastewater and Process Streams

Membranes Built with ZwitterCore™

Reliable pre-treatment regardless of variable leachate composition

Removes suspended and dissolved contaminants larger than 1 nm

Membranes built to handle up to 5% FOG and COD / BOD

Minimize digestate volumes

Reduce Digestate. Recover value.

Direct filtration solutions using ZwitterCo’s membranes can reduce digestate volumes by 50-70%, significantly reducing storage and hauling costs. These solutions typically have three primary stages:

- Bulk solids removal remove and dewater large particles and fibrous material. Solids can be repurposed as animal bedding, compost, or fertilizer.

- Expedition SF membranes for pre-treatment, removing suspended and dissolved organics larger than 1 nanometer. Concentrated organics can be sent to the primary dewatering process.

- Elevation RO membranes for polishing and nutrient concentration to achieve discharge-safe effluent. Concentrated Nitrogen, Phosphorus, and Potassium can be used as a nutrient-rich organic fertilizer.

meet discharge requirements

Effluent that meets standards.

Achieving effluent quality that complies with environmental discharge standards or is eligible for reuse in livestock watering or irrigation is the critical final step in a digestate treatment process. Typically, this requires:

- Total Dissolved Solids (TDS) < 1,000 - 1,500 mg/L

- BOD < 10 - 30 mg/L

- Ammonia < 5 - 10 mg/L

- Total Phosphorus (TP) < 2 - 10 mg/L

- Turbidity < 2 - 5 NTU

ZwitterCo’s Elevation RO membranes, which may be used in combination with ammonia stripping or final biological treatment depending on local standards, can remove TDS and nutrients while maintaining the highest organics tolerance of any reverse osmosis product.

Reduce membrane operating costs

Run Longer, clean less.

With ZwitterCo’s fouling resistant, Elevation RO membranes, biogas facilities that currently use traditional RO products can reduce utility and operating costs through multiple mechanisms, including:

- Switching from formulated cleaners to generic chemicals

- Less downtime and higher system productivity

- Less cleaning means less water and energy during CIP

- Less wear & tear from cleaning yields longer membrane life

Formulated cleaners are expensive. By switching to Elevation RO, which only uses generic caustic and acid during CIP, operators can eliminate formulated cleaners and reduce their chemical OPEX by 95%.

Ensure steady, reliable operations

Handle variability. Maintain flow.

By changing from conventional reverse osmosis to ZwitterCo’s Elevation RO membranes, biogas plant operators can increase their limits and tolerance for TOC, O&G, and COD and the membranes will be more adaptive to changes in digestate composition.

For digestate that needs more robust pre-treatment, ZwitterCo’s Expedition SF membranes remove contaminants larger than 1 nanometer, can handle up to 5% FOG, and can be cleaned with chlorine, maximizing treatment efficiency and producing ideal feedwater for downstream RO