Save Time and Money While Maximizing Productivity

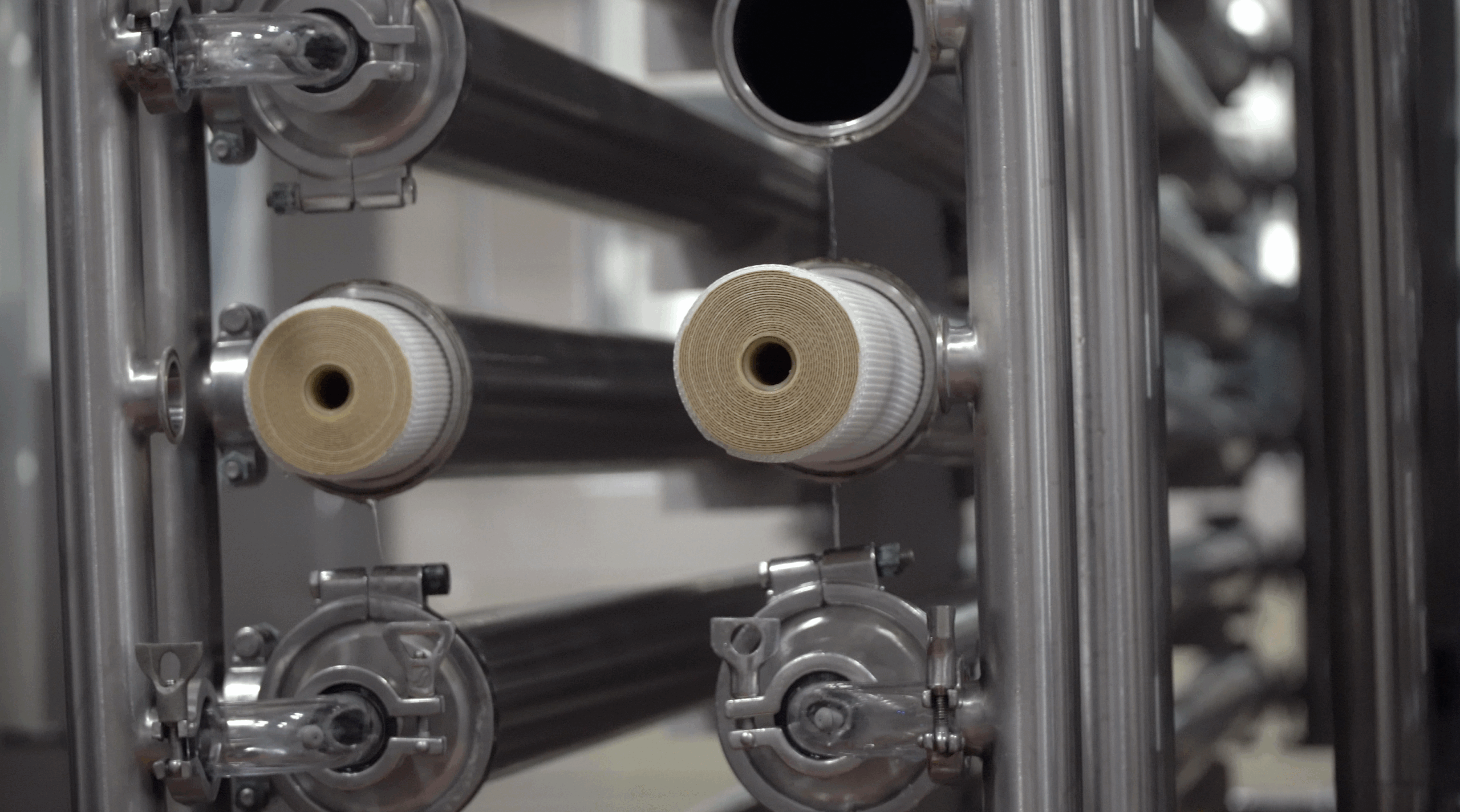

Evolution sanitary membranes minimize gel layer formation to maximize productivity during operation and fully recover their performance with a shorter, faster, lower-cost cleaning program that saves an hour or more every day.

Zwitterionic Technology Unlocks Anti-Fouling Membranes for Dairy Processing.

Evolution membranes feature a patented zwitterionic chemistry which serves as a permanent barrier to irreversible organic fouling, making them perfect for whey, milk, and other dairy streams. This proprietary anti-fouling chemistry is extremely hydrophilic while actively displacing or repelling organic compounds so that they cannot adhere to and foul the membrane.

By offering the highest resistance to organic fouling, these membranes minimize gel layer formation, resulting in higher productivity for dairy processors. Evolution membranes also simplify cleaning programs so that users can save over an hour of time each day and cut cleaning costs by over 50%, all without making system modifications.

Dairy Processing Applications

What challenges can ZwitterCo Evolution membranes solve for you?

whey & milk protein concentration

Reduce your cleaning costs by 50%.

With Evolution membranes, your cleaning programs are easier and shorter, enabling more uptime for operators to focus on other important tasks. With easier cleanings and less chemicals, plants enjoy significantly reduced time and labor required for maintenance.

Minimize gel layer formation, maximize productivity.

Evolution membranes feature the highest resistance to organic fouling, which reduces gel layer formation at the membrane surface and leads to higher sustainable average flux. This leads to more output, more uptime, more time for maintenance, and protection against equipment failure for dairy processors.

Simplified & sustainable operations.

Evolution membranes simplify cleaning programs and require fewer chemicals, while also reducing freshwater demand, energy consumption, and amount of wastewater generated.

- Reduced pumping

- Less water

- Less heating of CIP solutions

- Decreased chemical usage

- Reduced energy requirements

Improve your OPEX.

In whey protein concentration applications, Evolution membranes significantly reduce freshwater demand through their simplified cleaning process.

Reduced Operating Costs

With lower cleaning costs, decreased water usage, less wastewater generated, and lower energy requirements, Evolution membranes offer a significant decrease in OPEX.

Increase in Uptime

Evolution membranes offer more uptime due to shorter cleaning programs, freeing operators to work on other priorities.

Product Concentration

Simplify cleanings & reduce chemical usage.

Evolution membranes offer easier and quicker cleaning programs that require fewer chemicals, aligning with sustainability goals and cutting operational expenses for dairy processing companies.

Review our on-demand webinar to learn more about increased productivity with Evolution membranes.

Achieve a higher average flux.

Evolution membranes contribute to increased productivity by simplifying cleaning programs and achieving a higher sustainable average flux, which has been observed in multiple tests.

Because the anti-fouling nature of the membranes minimizes foulant build-up at the membrane surface, operators can experience a higher membrane flux.

Meet sustainability goals.

Evolution membranes help dairy processors meet sustainability targets thanks to the benefits provided by a shorter and simpler cleaning program. These benefits include:

- Less freshwater demand

- Decreased energy requirements

- Reduction in chemical usage

- Less wastewater generation

Brochure

What would you do with more time?

Think about it – every step of your daily cleaning program takes about an hour. Each step uses chemicals and make-up water, creates wastewater to treat, and requires energy for heating, pumping, and recirculating the cleaning solution.

What if you could eliminate one or more steps?

Effluent Polishing

Eliminate the costly enzyme cleaning step.

Integrating Evolution RO membranes is proven to eliminate the use of enzymes, which is the most expensive step in a cleaning program. This cuts chemical costs by over 50% and saves about an hour of cleaning time.

Decrease freshwater consumption.

By eliminating cleaning steps and associated flushing steps, Evolution RO membranes reduce freshwater demand for dairy processors. Users can reduce freshwater consumption for cleaning by 40% or more by switching to Evolution RO.

A Midwestern US whey processor saved over 1,000,000 gallons (3785 m3) over 10.5 months of operation by switching to Evolution RO.

Save time and money.

Evolution RO membranes increase productivity in effluent polishing systems by creating a higher sustainable average flux and simplifying cleaning programs.

Dairy processors can reduce overall cleaning costs by more than 50% and give valuable time back to operators to focus on production with these revolutionary anti-fouling membranes.

Mott Case Study

Speak with our engineers to discover ways that ZwitterCo can support positive changes at your plant. With our help, you can reduce your hauling and avoid heavy OPEX spend on plant expansion.

Learn More

Industrial Wastewater Reuse

ZwitterCo has only polymeric membranes that can filter high strength organic streams without rapid and irreversible fouling. More description here to describe the kind of solutions we offer for NMP.

Learn More

Challenging Surface Water Treatment

Write a description about how we solve challenging surface water treatment problems. EMP for pure water.

Learn More

High Value Protein & Co-Product Separation

Write copy about our solution for protein bioprocessing co-product creation – EMP Process.

Remove Bulk Organics

Remove tough to fight organics, such as fats, oils, grease, and protein.

Fully Chlorine-Intolerant

Can endure aggressive cleaning without wear and tear

Runs at Low Pressure

Runs at low pressure by not removing salt, sugar, alcohol’s or other small molecules.

Replaces Biological Systems

Replace biological systems or coagulation/flocculation processes commonly used to treat organics.

CASE STUDY

Optimizing Cleaning in a Dairy Effluent Polishing System

Proving ZwitterCo Evolution RO simplifies cleaning programs

Shorter and faster cleaning program by eliminating the enzyme step

Greater than 50% reduction in membrane cleaning costs

Operations with like-new performance since August 2024

CASE STUDY

The Impact of Evolution Membranes at Solugen

Discover how Evolution SF membranes saved time and money at a Houston bioprocessing facility

Greater than 400% cost savings in just nine months

Over 100% improvement in cycle times

Full flux recovery with simple cleanings