Membrane solutions for historically unfilterable streams.

Expedition membranes are rugged, industrial products designed for years of service in the toughest wastewater and process applications. They are built to handle extreme levels of FOG, COD, and other organics and are backed by ZwitterCo’s unique extended warranties and comprehensive service plans.

With Expedition membranes, complex wastewater treatment and reuse applications can be simplified down to direct filtration solutions, dramatically lowering costs and increasing operating reliability.

Enable Wastewater Reuse

Expand water available for production by recycling wastewater with a simple, filtration-based approach.

Unprecedented Fouling Resistance

Treat previously unfilterable streams with membranes that can handle up to 5% FOG and other organics.

High Uptime and Easy Cleaning

Fast cleaning cycles with generic chemicals restore performance quickly and keep membranes operating for years.

Reliable Operations

Proven to recover from major water quality upsets and adapt easily to changing industrial environments.

Backed by ZwitterCo

The only membranes with a fouling guarantee. Extended warranties and service plans can offer greater peace of mind.

Built with ZwitterCore™

Uses revolutionary ZwitterCore™ technology to unlock new wastewater or process solutions.

Unlock new wastewater and process solutions

Superfiltration Membrane

Expedition SF

Ideal pre-treatment membrane to remove complex organics before polishing or discharge

Built with ZwitterCore™

>99% removal of FOG, turbidity, and compounds > 1 nanometer

handles up to 5% FOG, proteins, and other organics

Safe to clean with chlorine or other oxidizing agents

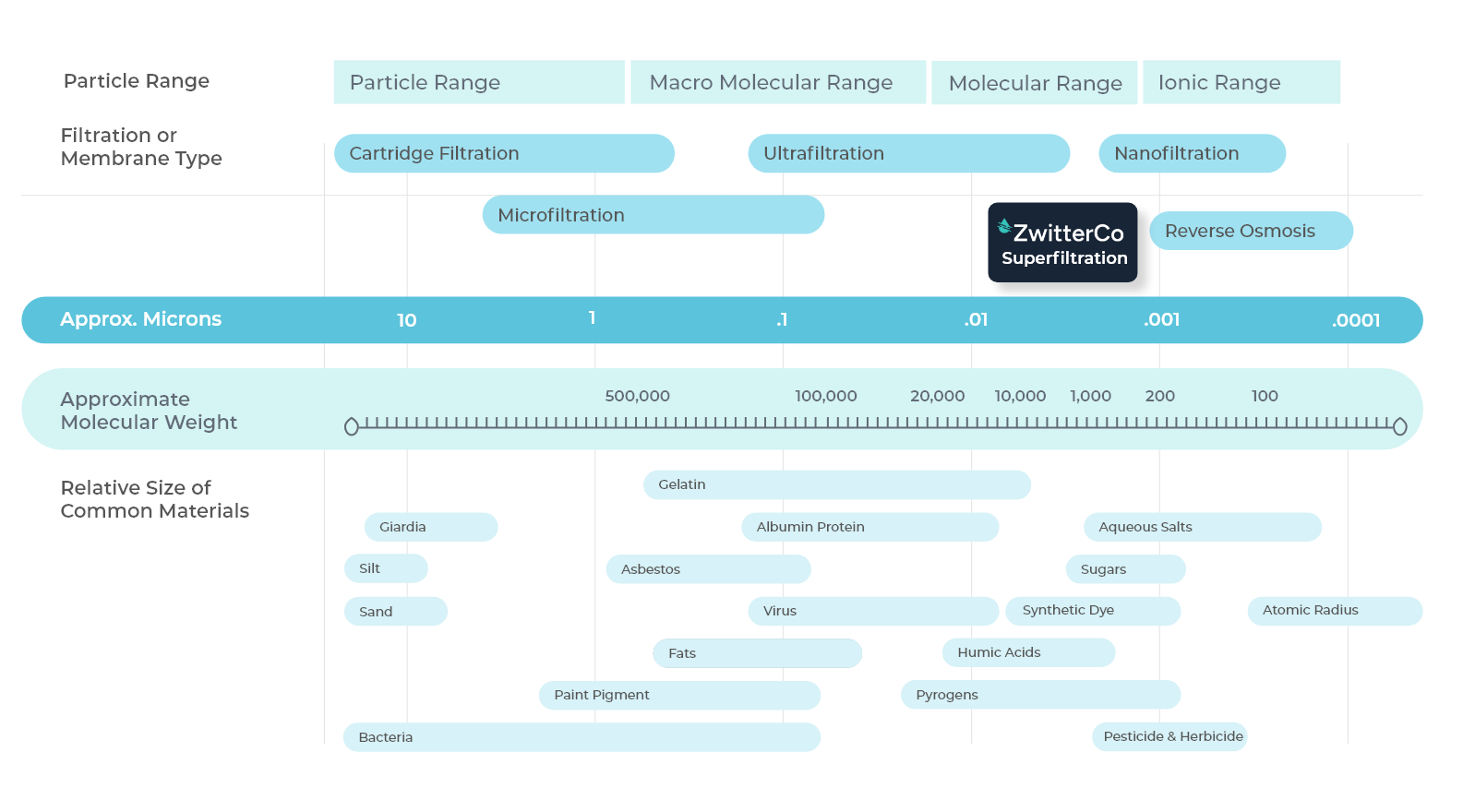

What is Superfiltration?

Membranes in this class may be described as “tight UF”, “open, non-softening NF”

Ideal Pre-treatment Membrane for Complex Streams

By completely removing of FOG, turbidity, and macro-molecular compounds, SF is an ideal pre-treatment ahead of polishing technologies like reverse osmosis to enable effluent reuse or compliant discharge.

High Organic / Low Salt Rejection

SF membranes demonstrate high NF-like organic rejection and low UF-like salt rejection (< 10% rejection of divalent ions).

One Nanometer, Size Selective Separation

SF membranes demonstrate size-selective removal of compounds larger than 1 nanometer, like dissolved proteins, starches, and humic acids.

Where to apply Expedition SF membranes

SF IS USED FOR

Pretreating streams with heavy or non-biodigestable organics

Conventional technologies used to pretreat reverse osmosis – including DAF + UF, multi-media + UF, and MBR – experience operating cost spikes, upsets, and fouling challenges in applications with hard-to-break-down or highly concentrated organics. Expedition SF provides adaptive and easy to maintain pre-treatment solutions, regardless of the organic composition of feed water.

SF IS USED FOR

Concentrating valuable organics without in-line chemicals

In many food processing and industrial applications, valuable organics that can increase product yields (i.e., oil or starch) or be valorized (i.e., converted to animal feedstocks or renewable natural gas) are discharged in wastewater. Expedition SF can concentrate these valuable organics without in-line coagulant or flocculant dosing, creating new revenue streams from waste.

SF IS USED FOR

Wastewater concentration before hauling or evaporation

In liquid organic waste management – whether through offsite hauling or in Minimum or Zero Liquid Discharge (MLD, ZLD) processes using thermal technologies – removing excess water is a major cost driver. Expedition SF is designed to dewater organic streams efficiently and without costly membrane fouling, delivering the lowest total cost solution.

SF IS USED FOR

Industrial process effluent reuse

In many food and industrial processes, effluent streams like evaporator condensate, cooling tower blowdown, and equipment wash water have residual organic contaminants that make them difficult to recycle. Expedition SF can remove trace organic contaminants without desalinating, providing a low-cost, low energy means to make these effluents eligible for non-potable reuse.

Top Applications

Faq

FAQs for Expedition

Here you’ll find clear answers to the questions we get most often from customers in the field.

Superfiltration membranes are a new separation class between ultrafiltration and nanofiltration. ZwitterCo superfiltration membranes deliver high fouling resistance, low energy requirements, wide pH tolerance, and the ability to be cleaned with chlorine. ZwitterCo’s Superfiltration delivers permeate quality beyond conventional UF, including partial removal of dissolved organics. It can operate as a standalone system or serve as a robust pretreatment to RO in demanding wastewater applications.

ZwitterCore™ is a new type of membrane technology using ZwitterCo’s patented zwitterionic chemistry. ZwitterCore membranes use water-permeable zwitterionic copolymers with precise selectivity to enable new paradigms in membrane processes. ZwitterCore membranes are composite materials built for the toughest organic fouling challenges, with high chemical resistance and extreme fouling resistance. ZwitterCo Expedition membranes are built from revolutionary ZwitterCore technology, enabling the treatment of previously untreatable wastewater streams.

ZwitterCo Superfiltration has a nominal pore size of 1.5 nm (0.0015 micron), corresponding to a nominal molecular weight cut-off (MWCO) of 1,000 Da (1 kDa). Rejection of suspended or emulsified materials including oil, grease, turbidity and suspended solids is virtually 100%. In addition, this pore size is small enough to reject even larger dissolved organic molecules such as protein, polysaccharide, and lignins. For more specific guidance on your particular water chemistry, speak with a ZwitterCo Sales Representative.

We offer fiber-glassed spiral-wound membrane elements built with oil-resistant components in standard industrial sizes 8”, 4” and 2.5” with 46 mil diamond-type feed spacers. These membranes are most commonly used in membrane processes with high crossflow designs and operate at relatively low pressure (typically 5-10 bar).

ZwitterCo Expedition SF membranes are designed to resist fouling and are easy to clean, even when treating extraordinarily difficult feed streams Expedition SF membranes use a fast maintenance wash procedure to restore performance when necessary, which takes about an hour and can be used anywhere from once per day to once per week, depending on the water chemistry. Unlike a traditional clean-in-place (CIP) procedure which can take an entire workday, maintenance wash procedures can be automatically completed in a fraction of the time.

Yes – Expedition SF membranes provide a permeate quality that is superior to even ultrafiltration pretreatment. Superfiltration can resolve water quality issues like SDI, turbidity, TSS, and oil & grease, and reduce TOC, BOD, and COD. Please note that Expedition SF is not a “softening” membrane, and care must be taken in downstream RO to address any risks related to scaling from mineral hardness.

- Landfill Leachate

- Food & Beverage

- Meat & Poultry

- Seafood

- Potato & starch

- Oil & Gas

- Heavy industry

- Untreated industrial wastewater

- Process effluent

- Primary or secondary treated industrial wastewater

- Secondary or tertiary effluent as feedwater

ZwitterCo stands by its technology and is proud to offer several options for reducing customer risk exposure. For Superfiltration systems purchased from ZwitterCo, comprehensive service plans are available that include membrane replacements as well as cleaning costs. For membranes contained in certified systems purchased from ZwitterCo partners, extended warranties that guarantee element life (including failure due to organic fouling) are available.

Expedition SF membranes are designed for the heavy demands of wastewater use, while Evolution SF is a food-grade filtration product held to strict regulatory requirements. These membranes and elements are not interchangeable.

Let's talk.

Whether you’re curious about our membrane technology, want to conduct a feasibility study, or are ready to get started on a project, we’re excited to speak with you and your team.