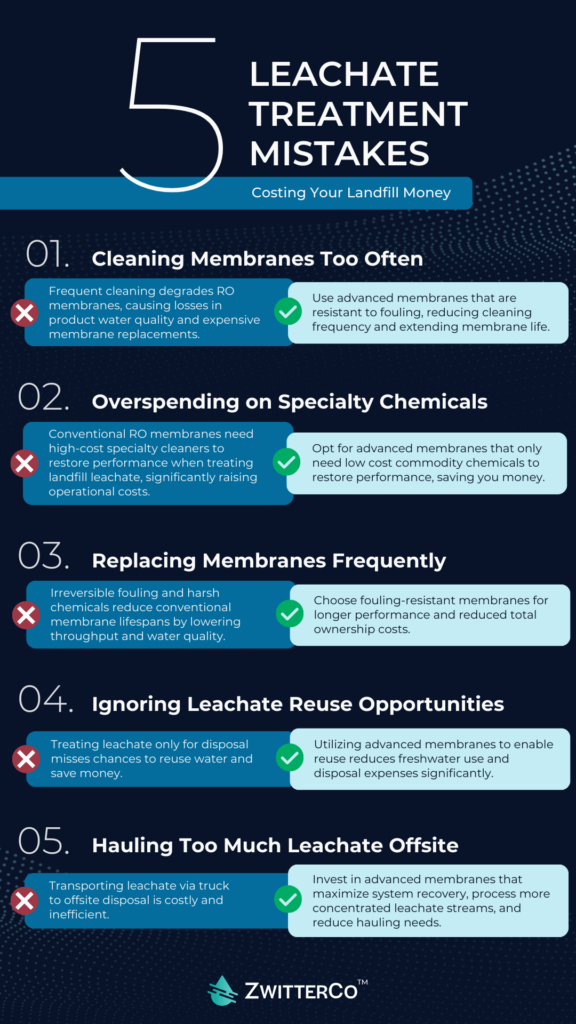

Landfill leachate treatment is a necessary but expensive part of waste management. Many landfill operators unknowingly make decisions that increase operating costs, shorten equipment life, and limit the potential for water reuse. Avoiding these common pitfalls can improve efficiency, extend membrane performance, and reduce overall costs. Here are five key mistakes to watch out for—and how to fix them.

1. Cleaning Too Frequently

RO membranes need regular cleaning to maintain performance, but cleaning too often can do more harm than good. Excessive cleanings degrade membrane materials over time, shortening their lifespan and requiring more frequent replacements.

The key is to clean at the right time—before irreversible fouling occurs but with as much time between cleanings as possible. Using durable, advanced membranes that resist fouling reduces the need for frequent cleanings.

Solution:

ZwitterCo’s zwitterionic RO membranes are designed with technology that is immune to irreversible organic fouling, maintaining high performance longer with fewer cleanings. This extends membrane life, improves uptime, and reduces OPEX associated with cleaning chemicals and labor.

2. Overspending on Specialty Chemicals

Formulated chemical cleaners are a major expense in landfill leachate treatment. Many conventional RO membranes require large amounts of expensive specialty cleaners to remove stubborn fouling. Over time, this leads to significant operational costs.

Solution:

Investing in membranes that require less aggressive cleaning chemicals can drastically lower costs without sacrificing efficiency.

Real-world example:

In a high-strength landfill leachate system, ZwitterCo RO membranes achieved 23 times cheaper cleanings than conventional RO. Instead of relying on large amounts of high-cost specialty cleaners, the ZwitterCo RO membranes were restored with far cheaper, commodity cleaning chemicals using a fraction of the specialty chemical dosing—all while maintaining high performance.

Read the full story here.

3. Replacing Membranes Too Frequently

RO membranes are a significant investment, and frequent replacements add considerable expense to your operating budget. Two major factors contribute to frequent replacements:

-

- Irreversible membrane fouling: Over time, fouling can permanently damage conventional RO membranes, making performance unrecoverable—even with strong chemical cleanings.

-

- Damage from excessive cleanings: Frequent chemical exposure degrades membrane materials, reducing filtration efficiency and product water quality, requiring more frequent replacements.

Solution:

ZwitterCo’s highly fouling-resistant RO membranes last longer in challenging landfill leachate environments, reducing replacement frequency and lowering total cost of ownership.

4. Ignoring Leachate Reuse Potential

Many landfills treat leachate only for disposal, overlooking opportunities for onsite water reuse. Reusing treated leachate can reduce both freshwater costs and waste hauling expenses. Common applications include:

-

- Dust control: Using treated water to suppress dust on landfill roads

-

- Equipment washing: Reducing reliance on freshwater for cleaning landfill machinery

-

- Surface water augmentation: Adding high quality product water to surface waters to improve local freshwater balances.

Tapping into these reuse opportunities can create cost savings and reduce environmental impact.

Solution:

Advanced membranes, like ZwitterCo RO, enable high-quality leachate treatment, helping water reuse become a more viable and cost-effective option.

5. Hauling Large Volumes of Leachate

Transporting untreated leachate offsite for disposal is becoming one of the most expensive solutions for landfill operators. The more leachate a landfill can treat and recover onsite, the less it needs to haul.

Many landfills struggle with high leachate volumes due to low system recovery rates and frequent cleaning and maintenance downtime. Conventional membranes often require conservative operation to prevent excessive fouling, leading to lower recovery and more leachate requiring disposal.

Solution:

Maximizing membrane system recovery is key to reducing hauling costs. Upgrading to advanced membranes like ZwitterCo RO enables landfill operators to process more concentrated leachate streams without excessive or irreversible organic fouling, allowing for higher recovery rates and more efficient onsite treatment.

Additionally, less system downtime for cleaning and membrane replacements means more leachate is treated per day—further minimizing hauling needs.

Avoiding these common landfill leachate treatment mistakes can result in significant cost savings, improved system efficiency, and longer-lasting membranes. Whether it’s reducing cleanings, cutting chemical costs, or increasing leachate reuse, upgrading to advanced membranes can make landfill leachate treatment more sustainable and cost-effective.

Want to learn how ZwitterCo RO membranes can optimize your landfill’s leachate treatment? Contact us today.

Click the Image Below to Download Graphic ⬇️