Reduce Cleaning Costs and Maximize Uptime

Built with ZwitterShield™ technology, Elevation High Rejection and Low Energy BWRO membranes are one-for-one substitutes for conventional RO elements that deliver unmatched reliability, reduced chemical costs, and faster cleanings, empowering industrial users to operate with confidence even when feed water is affected by organics.

Reduce Chemical Costs

Clean with commodity chemicals and cut cleaning costs by up to 90%.

More System Uptime

Achieves full performance recovery fast, simplifying cleaning and maximizing uptime.

Most Organic Tolerant

Offers the highest feedwater tolerance for organics (TOC, BOD, COD) and oil & grease, making it an ideal one-for-one replacement with significantly greater fouling resistance.

Faster Cleaning Cycles

Operates with up to 80% less frequent cleaning, lowering OPEX and boosting reliability.

It's time to elevate your membrane performance.

Elevation

High Rejection BWRO

Delivers high purity and excellent fouling resistance for demanding applications.

Built with ZwitterShield™

99.5% Stabilized Salt Rejection

99.2% Minimum Salt Rejection

10,000 gpd permeate flow

Elevation

Low Energy BWRO

Optimized for general use with lower energy demands and strong fouling resistance.

Built with ZwitterShield™

99.3% Stabilized Salt Rejection

99.0% Minimum Salt Rejection

10,800 gpd permeate flow

CASE STUDY

HIGH REJECTION BWRO

Learn how a landfill cut cleaning costs and membrane replacements with Elevation membranes

At a landfill leachate treatment facility in France, severe organic fouling led to daily cleanings and membrane replacements every 2–3 months, driving up OPEX and downtime. By switching to ZwitterCo Elevation High Rejection BWRO membranes, the operator achieved:

~50% reduction in cleaning cost per m³

43% reduction in cleaning water usage

Operational for >1 year with strong performance

CASE STUDY

LOW ENERGY BWRO

Learn how a U.S. based powerplant reduced RO cleaning frequency by over 70% with ZwitterCo

More uptime due to less cleaning

Consistently high permeate flow

Just 2 cleanings per year vs. 7 for conventional membranes

CASE STUDY

HIGH PRESSURE RO

See how a biorefinery achieved discharge compliance despite high feed variability with Elevation Membranes.

Stable permeate quality under wide feed variability

Reduced chloride load ahead of biological treatment

High recovery maintained across conductivity swings

CASE STUDY

HIGH PRESSURE RO

Learn how a landfill reduced cleaning costs by 96% by eliminating formulated cleaners with Elevation Membranes.

Cleaning with commodity cleaners only

96% reduction in cleaning chemical cost

No irreversible fouling; full recovery after each clean

Top Applications

Industrial Tertiary Wastewater

Landfill

Leachate

Food & Beverage

Chemical Processing & Refineries

High-fouling Surface Waters

Faq

FAQs for Elevation

Here you’ll find clear answers to the questions we get most often from customers in the field.

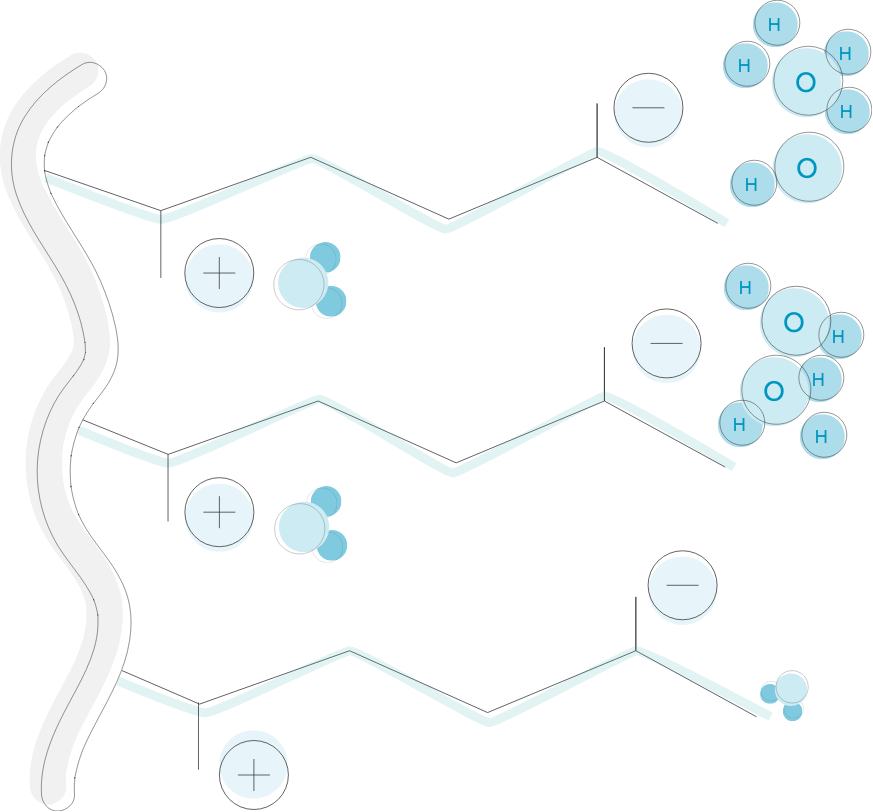

ZwitterShield™ is an additive membrane technology using ZwitterCo’s patented zwitterionic chemistry that may be bonded to various proven membrane chemistries to equip them with a permanent barrier to irreversible organic fouling. ZwitterCo Elevation membranes leverage industry-standard and proven membrane chemistries while featuring ZwitterShield technology to offer increased protection against irreversible organic fouling.

Yes. ZwitterCo Elevation 8” Low Energy BWRO 8040-34 and High Rejection BWRO 8040-34 are certified under NSF/ANSI/CAN 61: Drinking Water System Components – Health Effects, which means they meet the health-based requirements for materials that come into contact with drinking water.

Please refer to our official NSF website listing : https://info.nsf.org/Certified/PwsComponents/Listings.asp?Company=C0831746&Standard=061

Yes. ZwitterCo offers high-pressure, fouling resistant Elevation RO membranes that are specifically engineered to tolerate high concentrations of COD and other challenging contaminants commonly found in landfill leachate. Their robust performance makes them an ideal choice for reliable operation in difficult-to-treat industrial wastewater streams.

ZwitterCo membranes deliver superior value through performance and operational advantages. They offer:

- Reduced chemical cleaning costs

- Faster and easier cleaning cycles

- Increased system uptime

- High reliability in challenging applications

- Easier and safer plant operations

- Best-in-class organic fouling tolerance

These benefits make ZwitterCo membranes ideal for industrial applications where consistent performance, ease of maintenance, and operational efficiency are critical. Consult our sales experts to learn how these benefits can apply to your system.

ZwitterCo Elevation RO membranes are engineered for applications with high organic loading and challenging wastewater conditions.

They are an excellent fit if you operate in industries such as:

- Landfill Leachate Management

- Food & Beverage

- Chemical Processing & Refineries

- Heavy Industry

They perform reliably with feedwaters like:

- Wastewater or Leachate

- MBR Effluent

- Industrial Process Water

- High-Fouling Surface Waters

If your current system requires alkaline cleaning monthly or more often, or you’re replacing elements every 2 years or less, it may be time to consider ZwitterCo. Contact our team to assess the membrane fit for your specific operation.

ZwitterCo Elevation RO membranes are designed to be cleaned using commodity cleaners (e.g. caustic soda), making maintenance simple, cost-effective, and operator friendly. Elevation membranes respond quickly to cleaning, typically requiring shorter cleaning cycles and less aggressive protocols than conventional RO membranes. This ease of cleaning helps reduce downtime, improve membrane longevity, and lower operating costs. For specific cleaning recommendations, refer to ZwitterCo Elevation RO Cleaning Guide or speak with our technical team.

The following element diameters are currently offered for 40” long brackish water High Rejection and Low Energy elements with 34 mil feed spacers:

- 8.0” (8040)

- 4.0” (4040)

- 2.5” (2540)

The following element diameters are currently offered for 40” long High-Pressure RO elements with 34 mil and 50 mil feed spacers:

- 8.0” (8040)

- 4.0” (4040)

While membrane lifespan depends on system design, feedwater quality, and operating conditions, ZwitterCo Elevation RO is engineered for extended durability in tough applications. The leading cause of membrane failure is frequent chemical cleaning. Thanks to its high resistance to irreversible organic fouling, Elevation RO enables full performance recovery with fewer and simpler CIP steps, reducing membrane stress and extending membrane life. ZwitterCo is confident that Elevation RO membranes last longer than conventional RO membranes, helping reduce lifecycle costs and improve system reliability.

Let's talk.

Whether you’re curious about our membrane technology, want to conduct a feasibility study, or are ready to get started on a project, we’re excited to speak with you and your team.